Design properties of aluminium

Learn about the practical applications of useful properties of aluminium. Among many other important properties, the most useful properties of aluminium are the following:

- Corrosion resistance

- Thermal conductivity

- Specific Heat Capacity

- Electrical properties

- Specific strength

- Cold resistance

- Processibility

- Joinability

- Recyclability

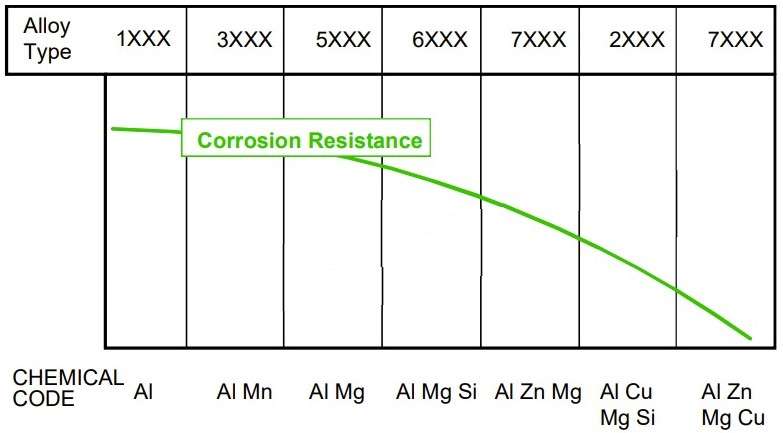

Corrosion resistance

- The thin natural oxide film is firmly “bonded” to the base metal.

- This provides many aluminum alloys with the property of significant resistance to corrosion in many atmospheric and chemical environments.

- The alloys of the 1xxx, 3xxx, 5xxx and 6xxx series are especially noted in this (Figure 1).

Figure 1 – The effects of alloying elements of aluminium alloys

Figure 1 – The effects of alloying elements of aluminium alloys

on their corrosion resistance [1]

Thermal conductivity

- Aluminum and aluminum alloys are good heat conductors.

- Thermal conductivity of aluminium is more than four times higher in aluminum alloys than in carbon steels.

- Aluminium has a high thermal conductivity, which means it can quickly transfer heat from one area to another.

- This property makes it suitable for applications where heat needs to be dissipated efficiently, such as in heat sinks or automotive radiators [5].

Figure 2 – Thermal conductivity of aluminum compared with other metals [1]

Figure 2 – Thermal conductivity of aluminum compared with other metals [1]

Specific Heat Capacity

- Aluminum has a relatively low specific heat capacity, which means it heats up and cools down quickly when exposed to heat sources.

- This property is advantageous for applications where rapid temperature changes are required, such as in cooking utensils or certain industrial processes [5].

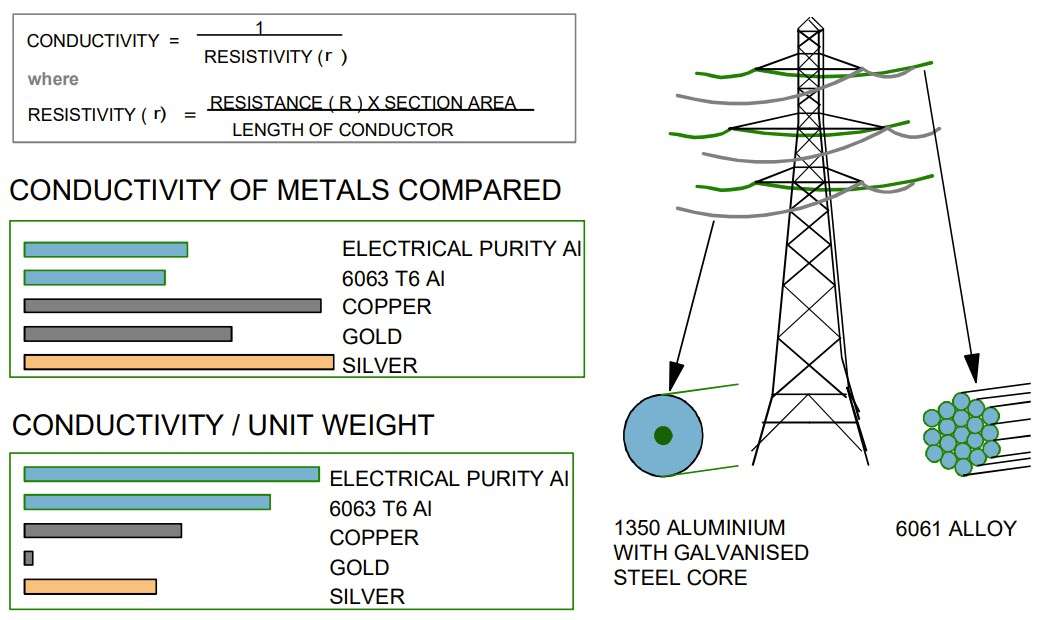

Electrical properties

- Pure aluminium and some of its alloys have very high electrical conductivity, second only to copper among metals used as conductors of electricity.

- Almost all high-voltage power lines use aluminium wires.

- They have a larger cross-section than equivalent copper wires, but also have half the weight.

- This allows to install supports less frequently and reduce their height (Figure 3).

Figure 3 – Electrical properties of aluminium [1]

Figure 3 – Electrical properties of aluminium [1]

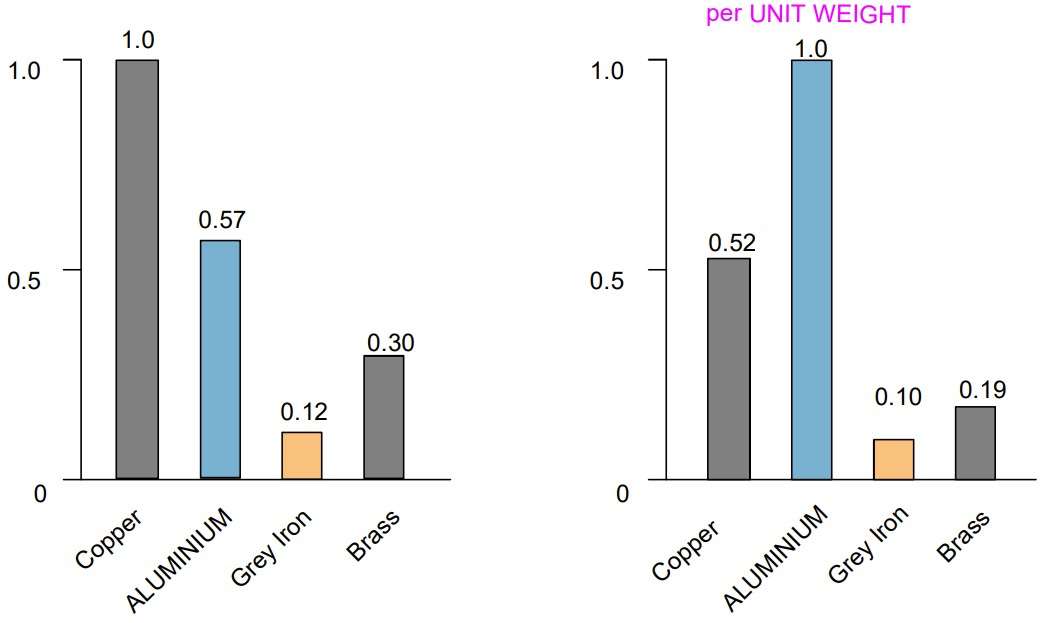

Specific strength

- Aluminium have high ratio of volume per unit weight (Figure 4). This ensures a high strength/weight ratio. This unit is called specific strength.

- It opens up many opportunities for replacing heavier metals without losing (or perhaps increasing) the load-bearing capacity of a product or part.

- This is the one of most useful properties of aluminium. Combined with good corrosion resistance, this propertiy ensures the widespread use in transport engineering (airplanes, cars, passenger cars).

Figure 4 – Volume per unit weight of aluminium compared to other metals [1]

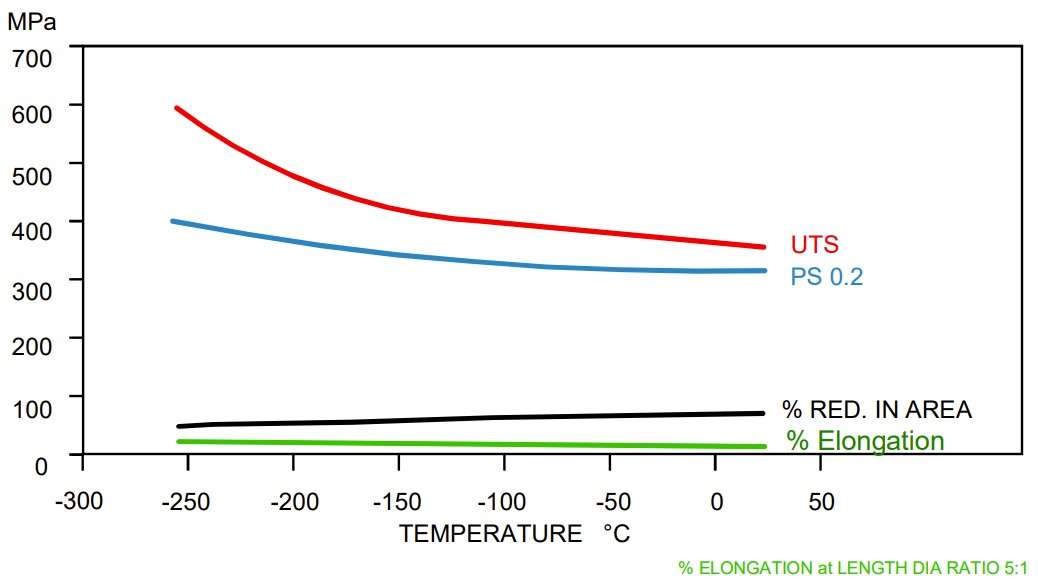

Cold resistance

- Aluminium alloys, especially the 3xxx, 5xxx and 6xxx series alloys, are ideal for low temperature applications.

- Numerous data confirm that their plasticity and viscosity, as well as strength, are higher at low temperatures, down to absolute zero, than at “room” temperature.

Figure 5 – Strength properties of aluminum alloy 6061,

Figure 5 – Strength properties of aluminum alloy 6061,

heat treated, artificially aged [1]

Processibility

- Aluminium alloys are easily machined by most known metalworking technologies and are particularly easy to extrude.

- Extrusion is the process of pressing heated metal through a matrix, forming profiles with a complex cross section.

- This usuful property of aluminum alloys makes it possible to produce extruded profiles from them with an almost unlimited variety of cross-sectional shapes.

- This allows the metal to be placed in those places and in such a way as to provide the profile with maximum load-bearing capacity under the influence of specified loads.

Figure 6 – Aluminium production processes [4]

Figure 6 – Aluminium production processes [4]

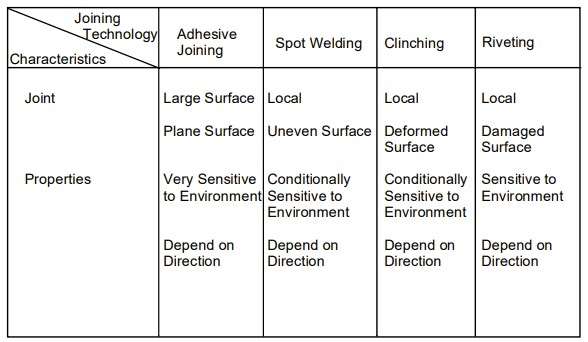

Jointability

- Parts made of aluminum alloys are connected using a large number of methods, including welding, soldering, riveting, screw connections, not to mention a wide variety of mechanical methods (Figure 7).

- Welding aluminum may seem difficult for those who only have experience with steels and try to transfer that experience to aluminum.

Figure 7 – Comparison of Properties of

Figure 7 – Comparison of Properties of

Different Joining Technologies [3]

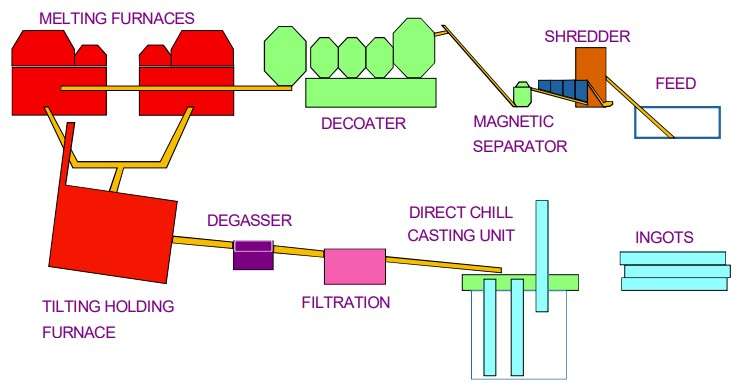

Recyclability

- One of the most useful properties of aluminium is that its life cycle is almost completely closed. Aluminium can be easily recycled and processed into almost the same high-quality products.

Figure 8 – A line for recycling used aluminium cans

Figure 8 – A line for recycling used aluminium cans

into ingots for rolling thin sheets to make new cans [2]

Sources:

1. TALAT 1501

2. TALAT 1102

3. TALAT 4105

4. https://www.researchgate.net/figure/Flow-sheet-of-the-aluminum-production-process

5. Aluminum vs Steel, thermal characteristics /Jeff Short