1050A aluminium

Learn about 1050A aluminium grade and its properties. Find out how this low mechanical strength alloy is processed and used in different industries.

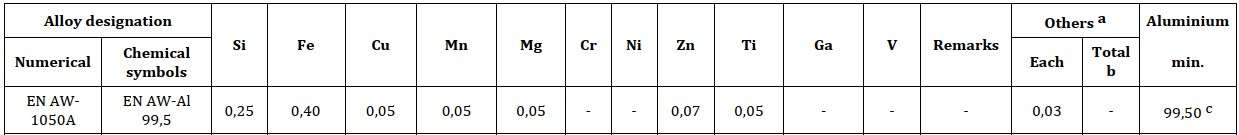

Chemical composition

Nominal chemical composition

99,5Al

Normalized chemical composition

Table 1 – Chemical composition of 1050A aluminium grade (EN 573-3)

Designations

- EN 573-3: EN AW-Al 1050А or 99,5

- International Registration (Teal Sheats) – Aluminum Association: 1050A

- Unified Numbering System (UNS): A91050A

- ISO 209: 1050A

- DIN 1725-1 (canceled): Al99.5 and 3.0255

See also: Aluminium grades

Characteristcs

- Wrought aluminium grade

- Aluminium content of not less than 99,5 %

- No special alloying elements.

- Belongs to 1xxx series

- Low mechanical strength

- High plasticity and formability

- Processed by extrusion, drawing, hot and cold rolling

Standard tempers

Extruded products – rods, tubes, profiles (EN 755):

- F

- O

- H111, H112

Cold-Products – Rods, tubes, profiles (EN 754):

- O

- H111

- H14, ःL6, H18

Rolled products – sheets, stripes, slabs (EN 485):

- F

- O

- H111, H112

- H14, ःL6, H18, H19

- H22, H24, H26, H28

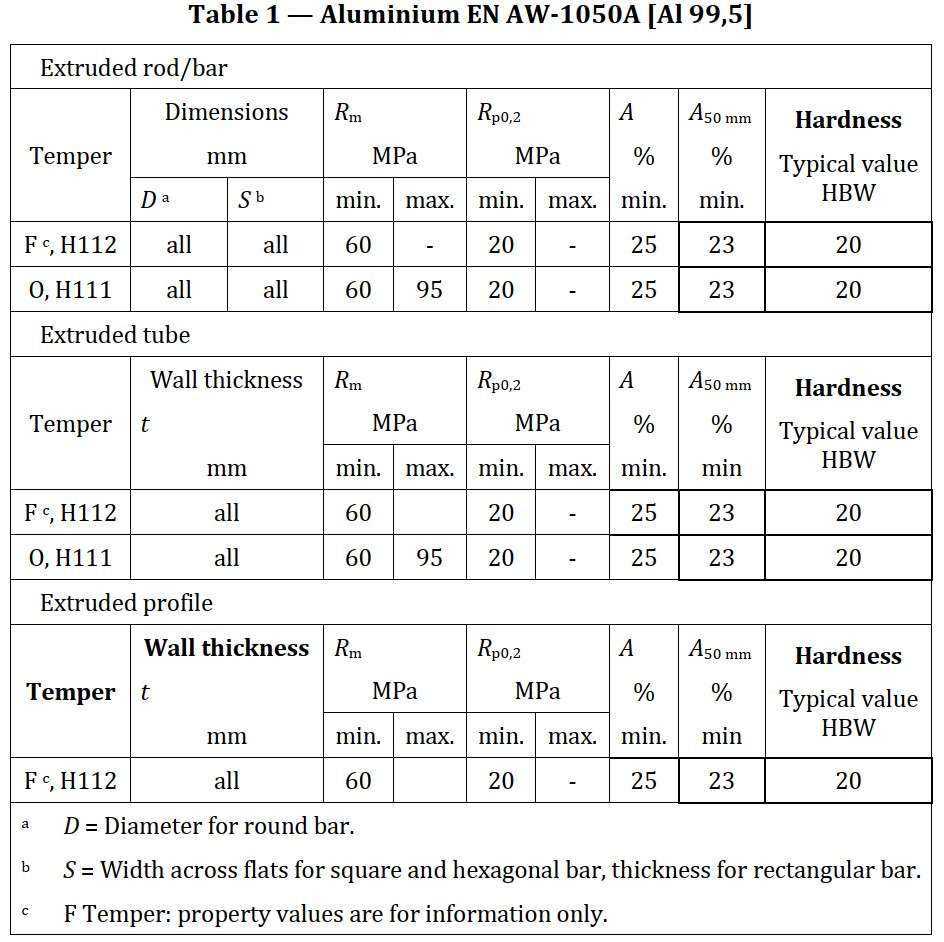

Mechanical properties

See also:Properties of aluminium

Mininal mechanical properties

Table 2 – Mechanical property limits (EN 755-2)

Physical properties (Temper O)

- Interval melting temperature, ºC: 650-658

- Density at 20 oC, kg /dm2: 2,705

- The linear expansion coefficient in the range 20-100 oC, μm / (m K): 23,8

- Thermal conductivity at 20 oC, W / (m K): 209

- Electric conductivity at 20 ºS: 61,3 % from the conductivity of the copper standard (IACS)

Technological properties

- The ability to cold-forming – High

- The ability to mechanical machining – low

- Weldability gas welding – High

- Weldability arc welding – high

- Weldability welding resistance – high

- The solderability – high

Application of 1050A aluminium

Examples:

- extruded pipes in bays, including, for heat exchangers

- fin

- chemical equipment

- food containers

- reflector lamps

- outer sheath of electric cables

- aluminium powder

Sources:

- International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys – Aluminum Association, 2015

- Aluminium & Cars. Design – Techology – Innovation, Edimet Spa, 2005

- Aluminum and Aluminum Alloys, ASM International, 1993.

- EN 573-3

- EN 755-2