A review of wrought aluminium alloys

Discover the characteristics and uses of wrought aluminium alloys. From high corrosion resistance to excellent formability, these alloys have a wide range of applications.

Wrought and cast alloys

All aluminium alloys fall into two main categories:

- wrought aluminium alloys

- casting aluminium alloys.

Wrought aluminium alloy is alloy primarily intended for the production of wrought products by hot and/or cold working [1].

Casting aluminium alloy is alloy primarily intended for the production of castings [1].

Wrought aluminium alloys series

According to the international designation system, all wrought aluminum alloys are subdivided into eight series (groups), depending on the alloying system of these alloys.

1xxx Series

- Includes unalloyed aluminum with a purity 99,00 % and higher (Table 1).

- Characterized by high corrosion resistance, high thermal and electrical conductivity, low mechanical properties and very good formability.

- Iron and silicon are the major impurities.

- Used mainly at electrical and chemical industries.

Table 1 – Chemical composition of 1xxx series aluminium alloys [3]

2xxx Series

- Copper is the principal alloying element, often with magnesium as a secondary addition.

- These alloys require solution heat treatment to obtain optimum properties; in the solution heat-treated condition, mechanical properties are similar to those of low-carbon steel.

- In some instances, precipitation heat treatment (aging) is employed to further increase mechanical properties.

- The alloys in the 2xxx series do not have as good corrosion resistance as most other aluminum alloys, and under certain conditions they may be subject to intergranular corrosion.

- These alloys in the form of sheet usually are clad with a high-purity aluminum, a magnesium-silicon alloy of the 6xxx series, or an alloy containing 1% Zn. The coating, usually

from 2 to 5% of the total thickness on each side, provides galvanic protection of the core material and thus greatly increases resistance to corrosion. - Alloys in the 2xxx series are particularly well suited for parts and structures requiring high strength-to-weight ratios.

- They are commonly used tomake truck and aircraft wheels, truck suspension parts, aircraft fuselage and wing skins, structural parts, and those parts requiring good strength at temperatures up to 150 °C.

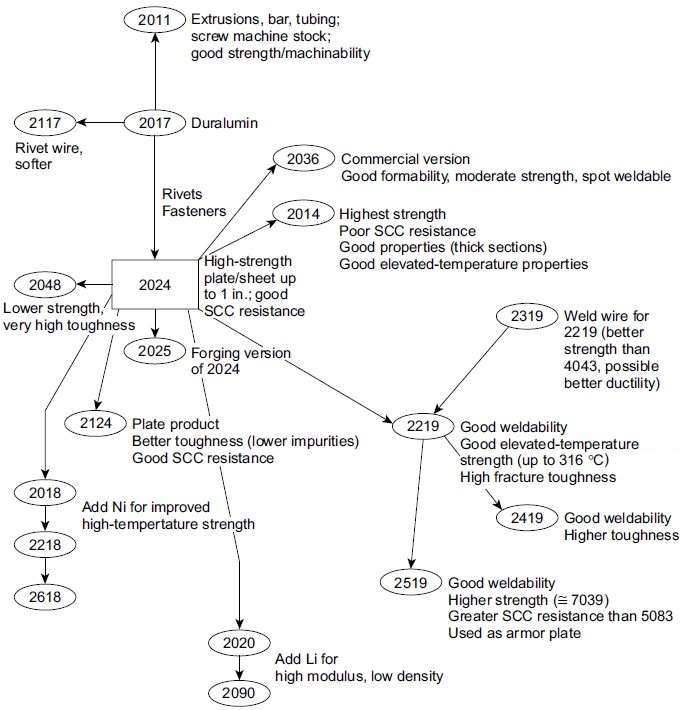

- Figure 1 shows the relationships between some of the more commonly used alloys in the 2xxx series.

Table 2 – Chemical composition of 2xxx series aluminium alloys [3]

Figure 1 – Relationships among commonly used alloys in the 2xxx series (Al-Cu) [2]

Figure 1 – Relationships among commonly used alloys in the 2xxx series (Al-Cu) [2]

3xxx Series

- Manganese is the major alloying element.

- These alloys generally are non-heat-treatable but have about 20% more strength than 1xxx series alloys.

- Only a limited percentage of manganese (up to about 1.5%) can be effectively added to aluminum. Therefore, manganese is used as a major element in only a few alloys.

- The popular 3003 alloy is widely used as a general-purpose alloy for moderate-strength applications requiring good workability.

- Alloys 3004 and 3104 are also popular. They are used for the manufacture of beverage can bodies

Table 3 – Chemical composition of 3xxx series aluminium alloys [3]

4xxx Series

- The major alloying element in 4xxx series alloys is silicon.

- Silicon can be added in sufficient quantities (up to 12%) to cause significant lowering of the melting range without producing brittleness.

- For this reason, aluminum-silicon alloys are used in welding wire and as brazingalloys for joining aluminum.

- Most alloys in this series are non-heat treatable, but when used in welding heat-treatable alloys, they pick up some of the alloying constituents of the latter and so respond to heat treatment to a limited extent.

- The alloys containing appreciable amounts of silicon become dark gray to charcoal when anodic oxide finishes.

- Alloy 4032 has a low coefficient of thermal expansion and high wear resistance; thus it is well suited to production of forged engine pistons.

Table 4 – Chemical composition of 4xxx series aluminium alloys [3]

5xxx Series

- The major alloying element is magnesium.

- Moderate-to-high-strength workhardenable alloys.

- Alloys in this series possess good welding characteristics and good resistance to corrosion in marine atmospheres.

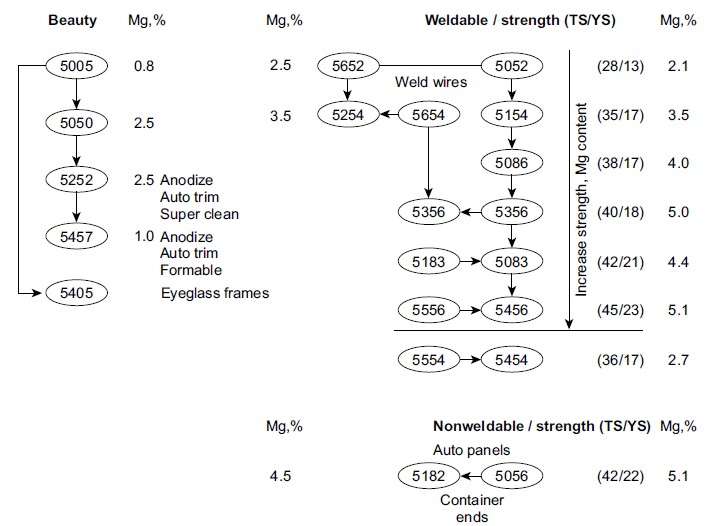

- Figure 2 shows the relationships between some of the more commonly used alloys in the 5xxx series.

Table 5 – Chemical composition of 5xxx series aluminium alloys [3]

Figure 2 – Relationships among commonly used alloys in the 5xxx series (Al-Mg).

Figure 2 – Relationships among commonly used alloys in the 5xxx series (Al-Mg).

Tensile strength (TS) and yield strength (YS) are in ksi units [2].

6xxx Series

- Alloys in the 6xxx series contain silicon and magnesium approximately in the proportions required for formation of magnesium

silicide (Mg2Si), thus making them heat treatable. - Not as strong as most 2xxx and 7xxx alloys.

- Have good formability, weldability, machinability, and corrosion resistance, with medium strength.

- Alloys in this heat-treatable group may be formed in the T4 temper (solution heat treated but not precipitation heat treated) (natural ageing).

- May be strengthened to full T6 properties by precipitation heat treatment (artifical ageing).

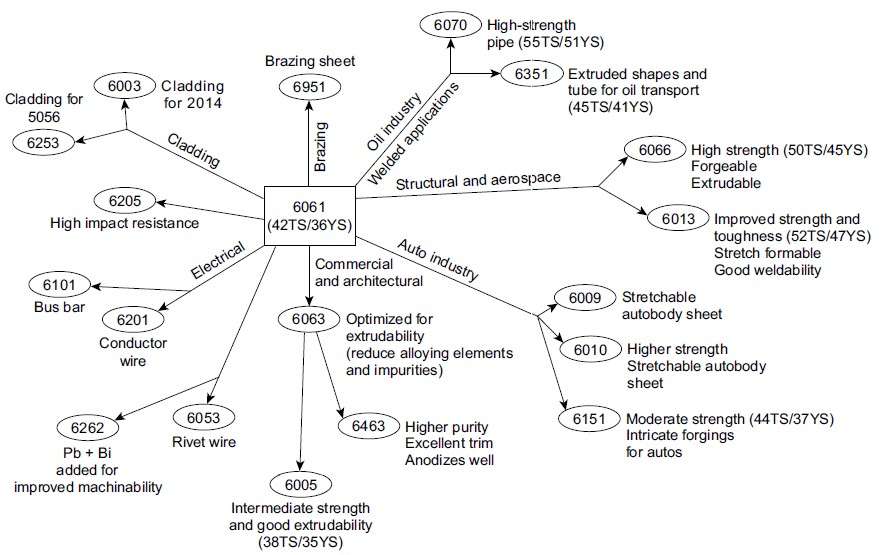

- Figure 3 shows the relationships between some of the more commonly used alloys in the 6xxx series.

Table 6 – Chemical composition of 6xxx series aluminium alloys [3]

Figure 3 – Relationships among commonly used alloys in the 6xxx series (Al-Mg-Si).

Figure 3 – Relationships among commonly used alloys in the 6xxx series (Al-Mg-Si).

Tensile strength (TS) and yield strength (YS) are in ksi units [2]

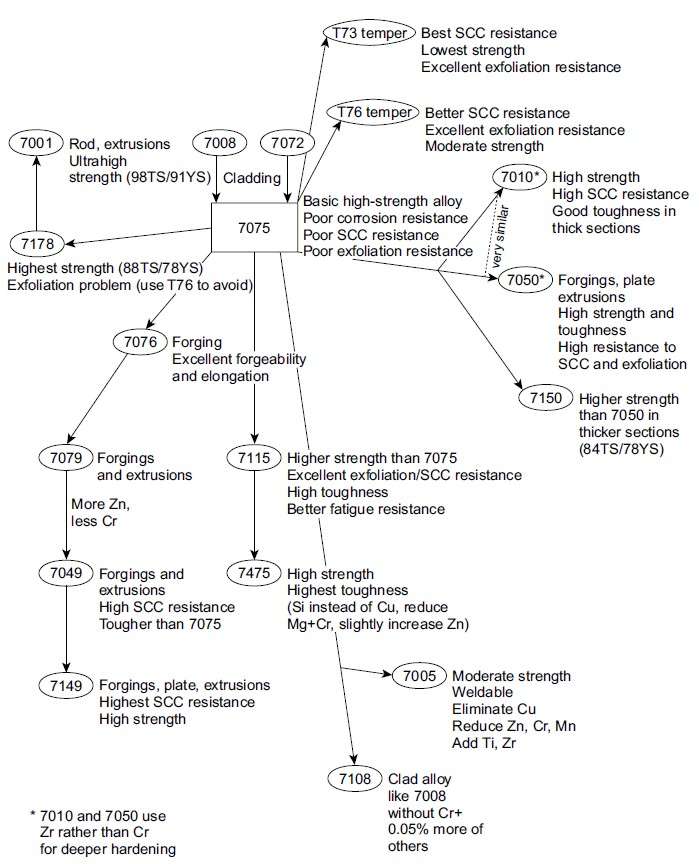

7xxx Series

- Zinc, in amounts of 1 to 8%, is the major alloying element.

- A smaller percentage of magnesium results in heat-treatable alloys of moderate to very high strength.

- Usually other elements, such as copper and chromium, are added in small quantities.

- Dilute additions of scandium also improve properties.

- 7xxx series alloys are used in airframe structures, mobile equipment, and other highly stressed parts.

- Higher strength 7xxx alloys exhibit reduced resistance to stress corrosion cracking and are often utilized in a slightly overaged temper to provide

better combinations of strength, corrosion resistance, and fracturetoughness. - Figure 4 shows the relationships between some of the more commonly used alloys in the 7xxx series.

Table 7 – Chemical composition of 7xxx series aluminium alloys [3]

Figure 4 – Relationships among commonly used alloys in the 7xxx series.

Figure 4 – Relationships among commonly used alloys in the 7xxx series.

Tensile strength (TS) and yield strength (YS) are in ksi units [2]

8xxx Series

- The 8xxx series combines alloys with different types of chemical composition (Table 8).

- Increased resistance to high temperatures is achieved through the use of dispersion-hardening Al-Fe-Ce alloys (example – alloy 8019) or Al-Fe-V-Si alloys (example – 8009), which are produced using powder metallurgy technologies.

- Reduced density and higher rigidity can be achieved in alloys containing lithium (example 8090). Alloy 8090, which is heat-hardening through aging, has replaced the medium- and high-strength 2xxx and 7xxx series alloys in some aerospace products (eg, helicopter components).

- Alloys 8030 and 8176 are designed specifically for aluminum wire and cable.

Table 8 – Chemical composition of 8xxx series aluminium alloys [2]

European and American alloys

As you can see, not all aluminum alloys that are presented in Figures 1-4 are present in Tables 1-8. This is due to the fact that European and American approaches to alloying aluminum alloys are somewhat different. For example, alloys 6060 and 6082 are “European” and are rarely used in North America. On the other hand, alloys 6063 and 6061 are popular in North America and are much less common in Europe.

Sources:

1. GAG Guidance Document 001 – Terms and Definitions – 3rd Edition 2011-01

3. DIN EN 573-3:2009