How Welding Heat Affects Aluminium

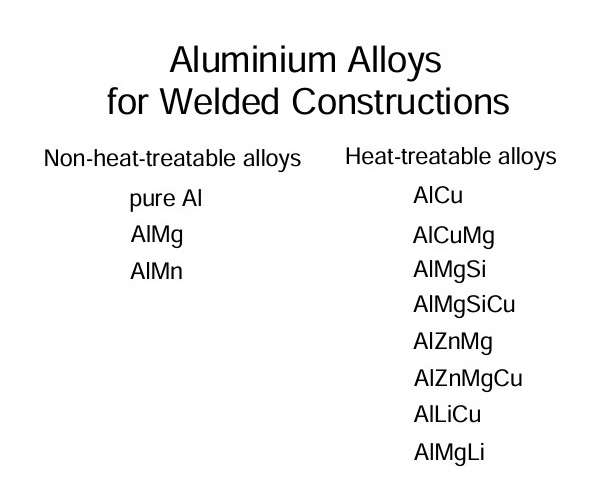

Aluminium Alloys for Welded Constructions

The strength of non-heat-treatable alloys is not affected by the welding heat. However, for cold worked alloys, the strength at the joint is reduced to that of the annealed state. The loss of strength depends on the heat input, which in turn depends on the process. Al-Mg types of alloys are more sensitive in this respect than the Al-Mg-Mn types of alloys. The heat-treatable alloys also lose their strength at the weld zone. However, the behaviours of Al-Mg-Si alloys and Al-Zn-Mg alloys should be differentiated.

Al-Mg-Si alloys

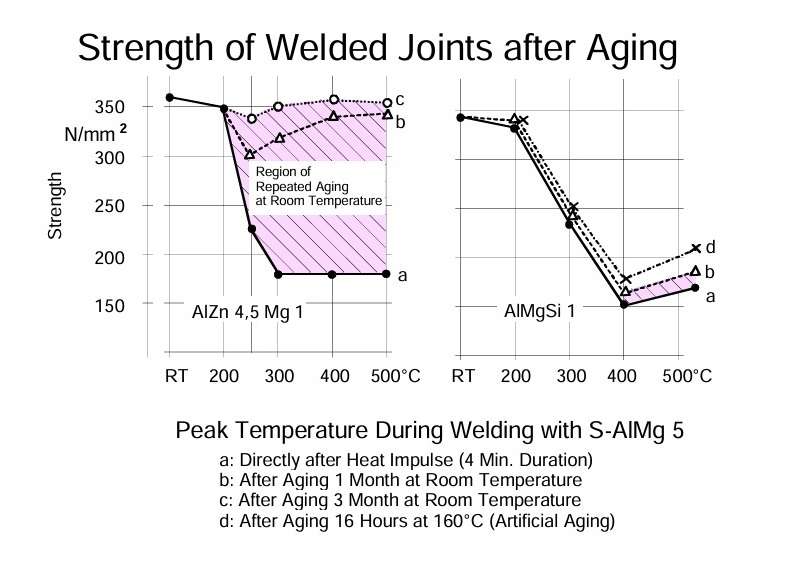

Al-Mg-Si alloys can be reversed to their original hardness only by repeating the solution treatment, quenching and ageing steps. This can, however, be seldom applied in practice due to the size of the constructions and the expected distortion.

Al-Zn-Mg alloys

Al-Zn-Mg alloys, on the other hand, require lower solution treatment temperatures and lower quenching rates for repeating the heat treatment. This behaviour is utilised for regaining the strength loss in the heat-affected zone. The welding heat itself is sufficient for solution treatment and the cooling that follows is sufficiently rapid for the quenching step. The fast cooling is a result of the heat being conducted rapidly away from the heataffected zone due to the good thermal conductivity of aluminium. The joint can then be aged at room temperature (natural ageing) or at elevated temperatures of up to 160 °C (artificial ageing).

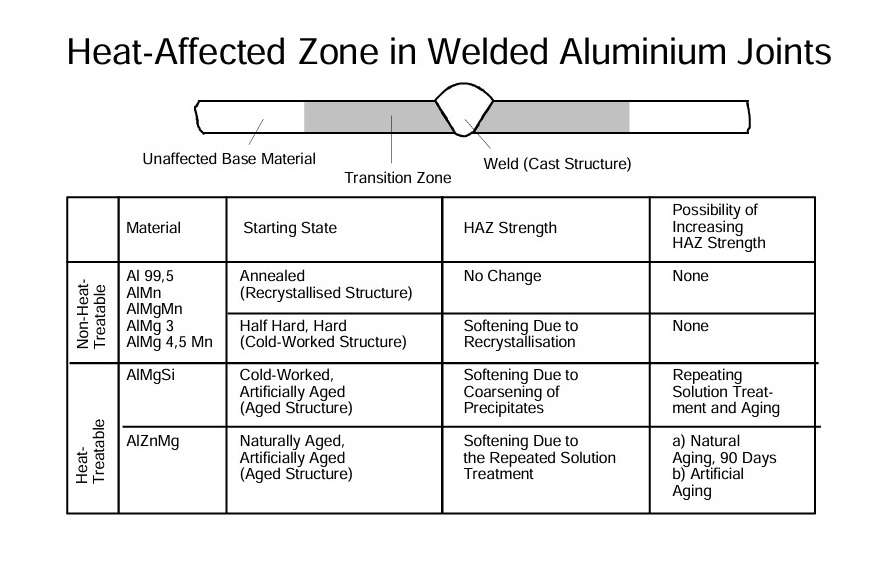

Heat-Affected Zone in Welded Aluminium Joints

The type of the material to be welded, i.e., whether or not it is a heat-treatable alloy, is decisive for the strength attained after welding. Non-heat-treatable cold-worked alloys cannot be reverted to the original cold-worked state (e.g. hard) after welding. The joint strength always corresponds to that of the annealed state. A different situation exists for the heat-treatable alloys. In principle, the weld zone which is in the annealed state after welding, can be reverted to the original aged condition by repeating the ageing steps of solution treatment, quenching and ageing. There are usually two problems: the large size of the welded constructions and the distortion which accompanies the quenching. The welding heat produces the self-ageing effect in the Al-Zn-Mg types of alloys. The welding heat suffices for the solution treatment and the fast cooling is equivalent to a quenching. The joint then ages at room temperature.

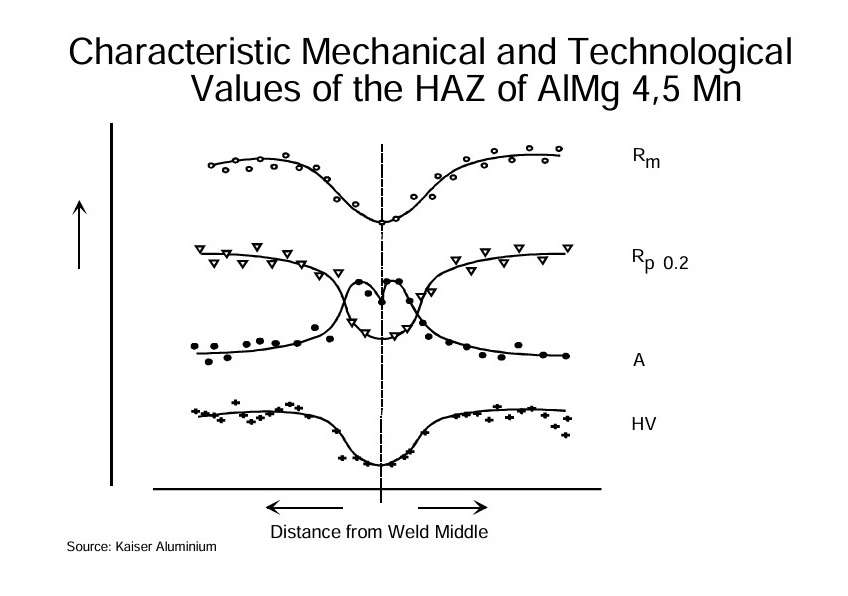

Characteristic Mechanical and Technological Values of the HAZ of AlMg4,5Mn. The loss in strength and hardness in the weld region is typical for aluminium and its alloys. The elongation values increase at first but then fall slightly at the weld middle, this fall being caused by precipitations. This loss of strength must be considered in designing the welded construction. Calculations should then be based on the reduced allowable stress.

Strength of Welded Joints after Ageing. The weldable, self-hardening Al-Zn-Mg alloys have to be handled differently than the other heat-treatable alloys. The reason for this is the relatively large solution treatment range (350 – 500 °C) and the slow ageing effect at room temperature (natural ageing). The solution treatment and quenching occur at much lower levels than for the other heat-treatable alloys. The full strength is regained after a room temperature ageing time of 90 days. This effect cannot be attained without additional heat input and quenching for Al-Mg-Si types of alloys. A slight increase of strength can be attained by artificial ageing.

With respect to cracking, the Al-Mg-Si types of alloys are better than the Al-Zn-Mg types of alloys, being less crack sensitive.

The source:

TALAT Lecture 4204 – Design Aspects / Ulrich Krüger – European Aluminium Association – 1994