About weld repair of aluminium wheels

Understand the risks and limitations of welding repairs on aluminium wheels. Explore the impact of welding on critical areas and why it is prohibited by industry standards.

Subject the use of repair weld in aluminium discs is highly relevant. Below we present information, which explains features and complexity repair welding aluminum wheels. This information is not intended to be a complete statement of the topic under discussion and not an instruction for welding aluminium wheels.

Regulations

Wheels are heavy duty vehicle components, of which largely depends on its safety. That’s why leading automobile manufacturers and the wheels are not allowed to perform them any repairs, including repair welding.

- Standard ISO 14400 clearly indicates, that the repair welding wheel drive should not be made, since this can introduce additional stresses in its critical regions [1].

- Organization EUWA (Association of European Wheel Manufactures) strictly prohibits the repair of damaged rims and disks of automobile wheels using heat, welding or adding any additional material [2].

At the same time,

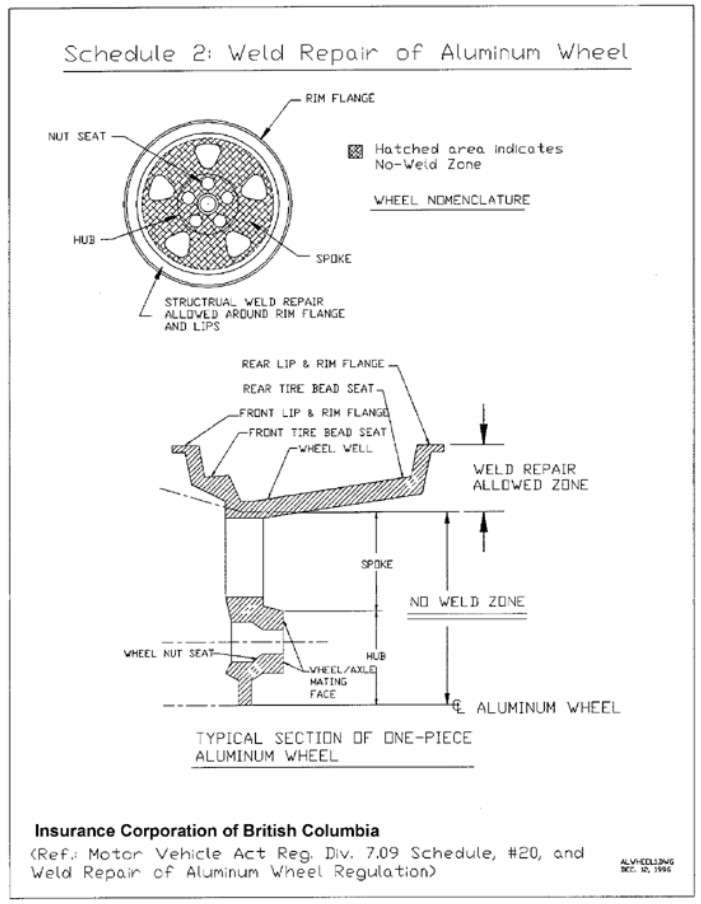

- Regional regulations in the Canadian province of British Columbia allow limited use of welding for wheel rim repairs [3] (Figure 1).

Figure 1 – Weld repair allowed and not allowed zones

Figure 1 – Weld repair allowed and not allowed zones

of typical of one-piece aluminium wheel [3]

Strength loss due to welding

The heat of the welding operation is conducted into the parent metal such that in any welded joint there are three distinct areas – the weld metal in a fusion welded joint, the HAZ in the parent material and the unaffected parent metal [4].

As-cast and annealed tempers

Aluminium alloys in the as-cast or annealed condition (F and O tempers) may be welded without any significant loss of strength in the HAZ. The strength of the weldment matching that of the parent metal.

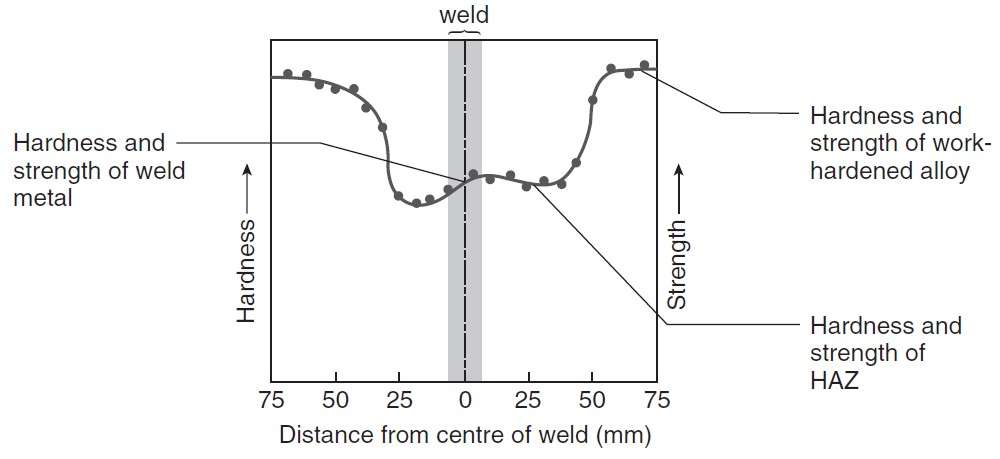

Cold-worked tempers

The cold worked alloys will experience a loss of strength due to recrystallisation in the HAZ. Recrystallisation begins to take place when the temperature in the HAZ exceeds 200 °C and progressively increases with full annealing taking place over 300 °C. Figure 2 shows a cold worked 5XXX alloy after TIG welding.

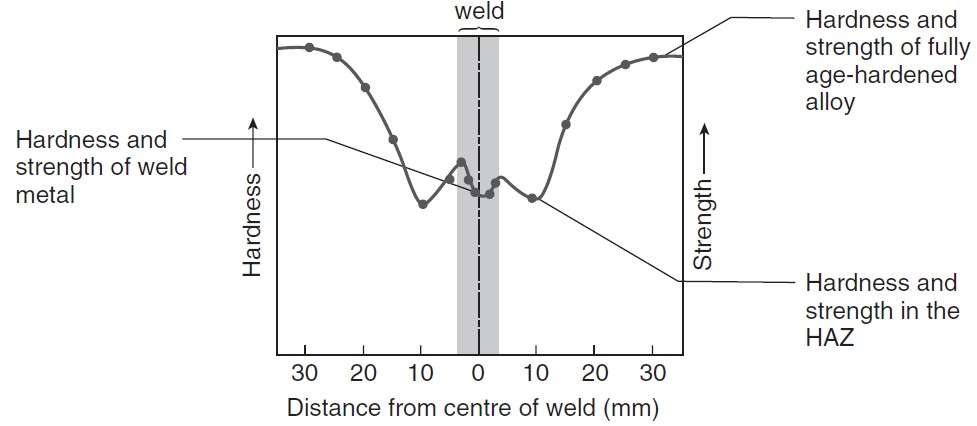

Heat-hardened tempers

In the heat-treatable alloys, the strength losses are caused by a dissolution of the precipitates in the 2XXX series alloys and a coarsening or overageing of the precipitates in the 6XXX and 7XXX alloys.These effects are illustrated in Figure 3.

Figure 2 – Effect of welding on strength in cold worked alloy [4]

Figure 2 – Effect of welding on strength in cold worked alloy [4]

Figure 3 – Effect of welding on 6061 T6 age-hardened alloy – as welded [4]

Figure 3 – Effect of welding on 6061 T6 age-hardened alloy – as welded [4]

Conclusion

When deciding on the application of repair welding aluminium wheels should be taken into account, in the HAZ of welding, mechanical properties of the base metal may be reduced.

For the purpose of a wheel disk and changes the mode of welding necessary, least, consider:

- wheel area: critical or non-critical

- alloy type: wrought or cast

- the chemical composition of the aluminum alloy;

- aluminum alloy temper (cast or annealed, heat-hardened, cold-worked).

Sources: