Ultrasonic welding of aluminium

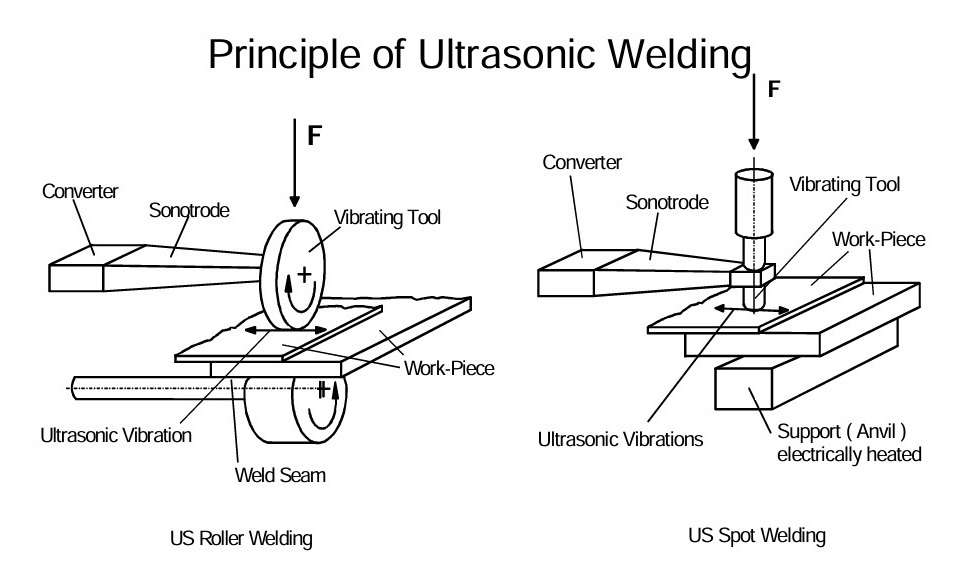

Principle of Ultrasonic Welding

In ultrasonic welding, frictional heat produced by the ultrasonic waves and force is used for the joining process. Ultrasonic waves (15 to 60 kHz) are transferred to the material under pressure with a sonometer. Welding times are lower than 3 s. The welding can proceed with or without the application of external heat (Figure 1).

Figure 1 – Principle of ultrasonic welding

Figure 1 – Principle of ultrasonic welding

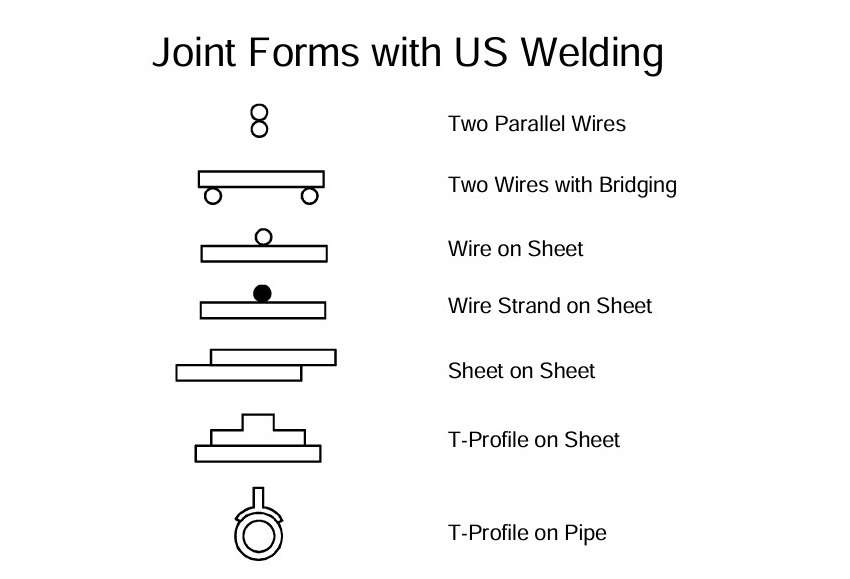

Joint Forms with Ultrasonic Welding

The principle of the process limits the allowable mass of material on the sonotrode side to a maximum of 10 g. The maximum thickness that can be welded, depends on the selfdamping characteristics of the work-piece material. A main advantage while welding aluminium is the fact that the vibrations break the oxide layer and transport it to the boundary regions. As a result, mechanical and chemical surface cleaning is not necessary. Surface coatings (e.g. coated wire) and impurities behave in a similar manner. Consequently, a main application area for ultrasonic welding is the contact joining of wires (Figure 2).

Figure 2 – Joint forms with ultrasonic welding

Figure 2 – Joint forms with ultrasonic welding

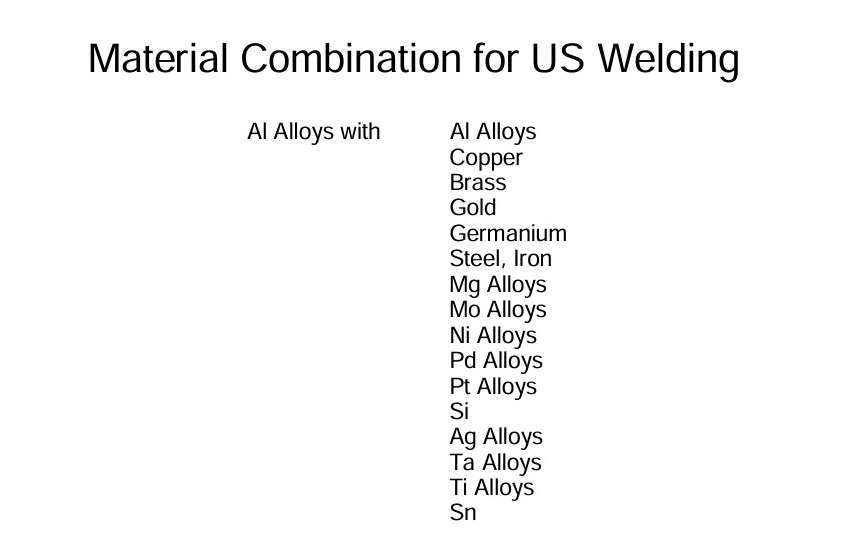

Material Combinations for Ultrasonic Welding

Ultrasonic welding is particularly suitable for joining aluminium and its alloys with each other as well as for producing composite joints with other materials (Figure 4400.03.03). In electrical and electronic applications, the frictional energy creates clean welding zones with low contact resistances. Hardness influences the weldability of composite joints with steel. Hard alloys are less suitable, since the plastic formability required for the joining is not sufficient. Very often an intermediate layer is used to overcome this deficiency.

Figure 3 – Material combination for ultrasonic welding

Figure 3 – Material combination for ultrasonic welding

The source:

TALAT Lecture 4400 – Friction, Explosive and Ultrasonic Welding Processes of Aluminium / Ulrich Krüger – European Aluminium Association – 1994