Tools for Machining Aluminium

Tools suitable for machining aluminium differ from those required for machining steel. Aluminium cannot be worked with tools which are used for steel. This video specifies the cutting materials and tool forms most suitable for machining aluminium.

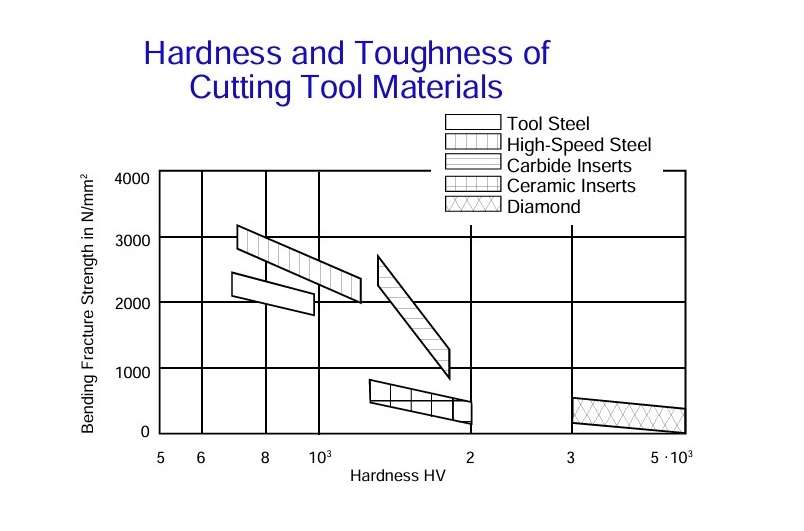

Aluminium is machined using tools made of tool steel, high-speed steel, cemented carbides and diamond. Ceramic cutting materials are not recommended for machining aluminium. Synthetic cutting materials which can be successfully used for machining steel, are not suitable for aluminium.

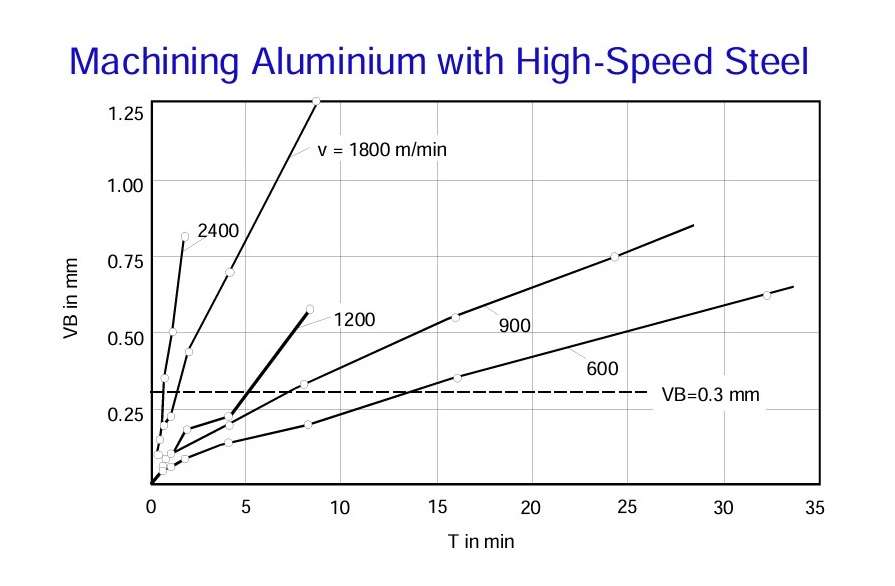

High-speed steels offer the following advantages: high toughness, high bending strength, ease of working, low price. For machining aluminium, the following main types of tools are used: twist drills, taps, milling cutters, form turning tools, profiling tools. These are mostly made of steel with 12 percent tungsten. HSS tools are used almost only for wrought aluminium alloys since wrought alloys contain only few hard inclusions and thus cause little tool wear.

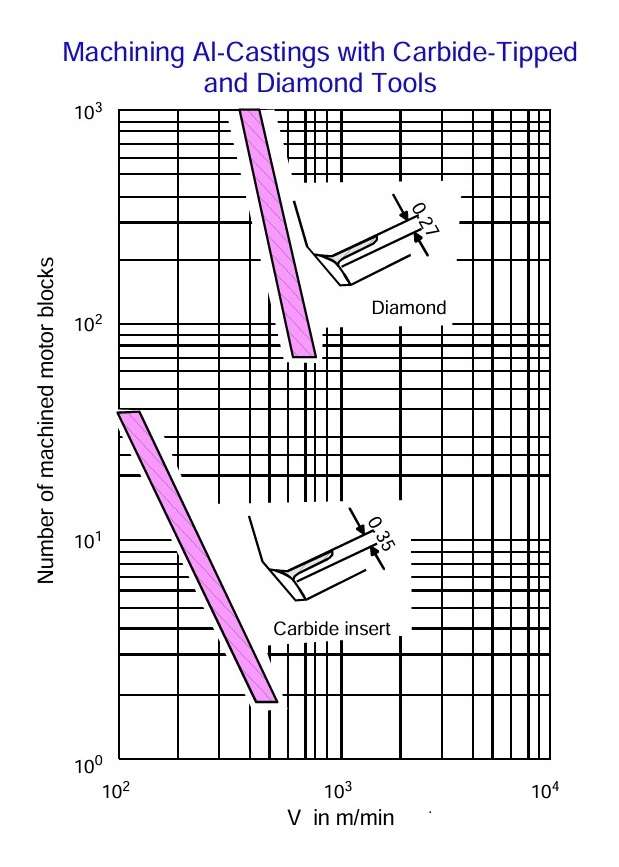

Casting alloys which have a relatively high abrasive action are mostly machined using carbide-tipped tools. High cutting speeds which are characteristic for machining aluminium, cannot be used with HSS tools. For economic reasons, carbide-tipped tools are being increasingly used for machining the less abrasive wrought alloys also. The extremely long tool operating life – of one week or more – and the high cutting speeds attainable, more than compensate for the higher price of carbide-tipped tools.

The extremely high hardness of diamond makes it a very suitable material for cutting tools. Such tools are used especially for machining hypereutectic aluminium-silicon alloys which, due to the coarse silicon inclusions present, are extremely abrasive and thus very difficult to machine. Compared to carbide-tipped tools, diamond tools have longer operating lives, higher precision and better operating stability.

Tools have to be designed keeping the processes which occur at the cutting edge in mind.

- A positive cutting angle should be used for tools for machining aluminium.

- The cutting edge should be smooth. Tools with polished cutting and free surfaces deliver very good results.

- The tool construction should be such as to allow sufficient stability even at the extremely high speeds used nowadays for machining aluminium.

These general comments pertain only to the turning process which is characterised by a clearly defined arrangement of tool and workpiece. For the other cutting processes, a number of other process parameters, which influence the tool design and construction, have to be considered.

During drilling, the chips cannot be transported freely but are instead forced out through the relatively narrow flute by frictional forces causing the chips to glide along the inside surface of the hole. When drilling aluminium, the drill used must take the deviation of diameter caused by the expansion of the material on one hand, and the differing amounts of expansion of tool and workpiece on the other into consideration.

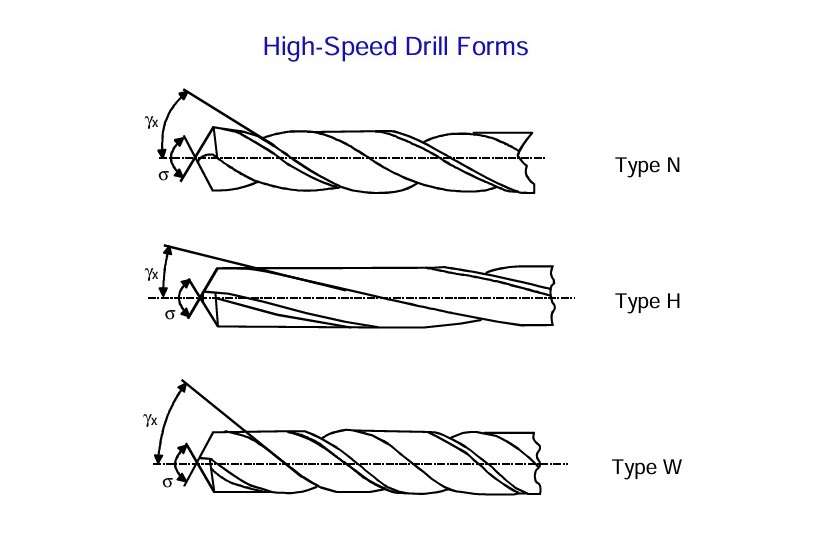

Twist drills are classified into three groups: N, H and W types. Each drill type has a different set of point and helix angles. The type W with a point angle of 140⁰ and a helix angle between 30⁰ and 40⁰ is suitable for aluminium.

Drills for aluminium differ from those for steel. One of the major differences is that they have the larger helix angle used (45⁰, compared to 25⁰ for steel).

It is generally recommended to use drills having keen cutting edges and polished surfaces for aluminium. A high polish in the flutes minimises friction and thus reduces material buildup.

Aluminium can be drilled using larger feeds than for drilling steel. Consequently, a much larger amount of chips has to be transported within the same period of time through the flutes.

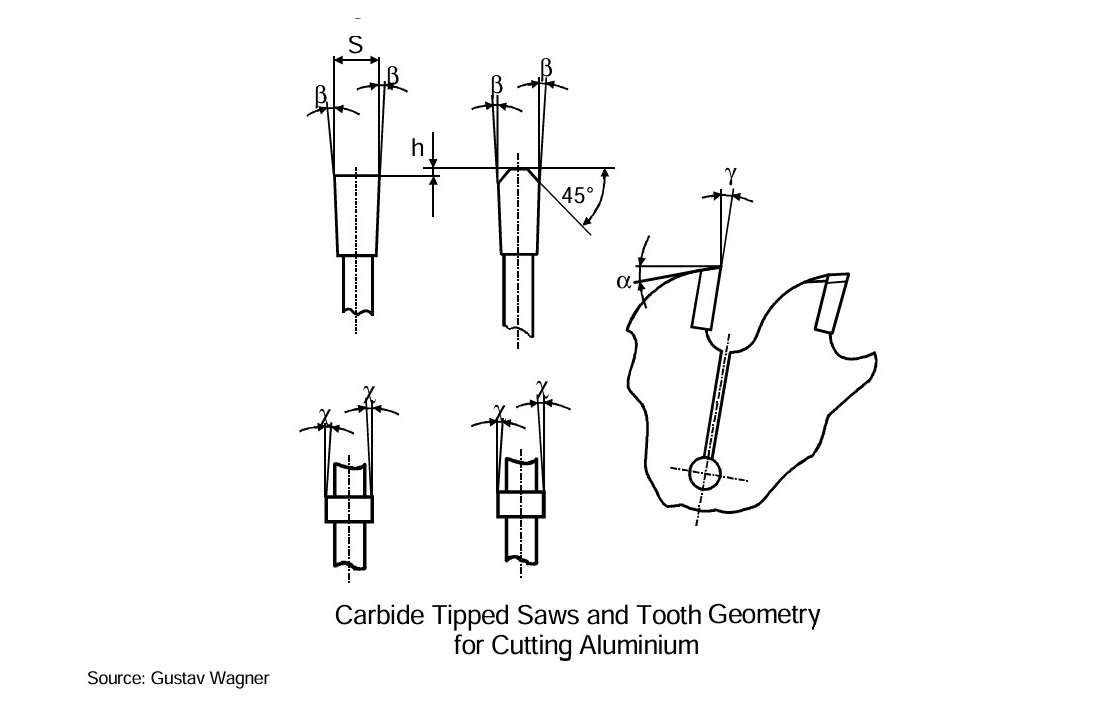

Either circular or bandsaws are used for cutting aluminium. The circular saws used are mostly carbide-tipped. Such saw blades are made of steel and have individually brazed carbide-tipped teeth. Chip-breaker and finishing teeth are arranged alternatingly on the circumference. The chip-breaker teeth are chamfered on both sides. The finishing teeth cut out the edges and a certain height difference.

The source:

1. TALAT Lecture 3100 – Machining of Products / P. Johne – European Alumnium Association – 1994