TIG welding of aluminium: equipment and materials

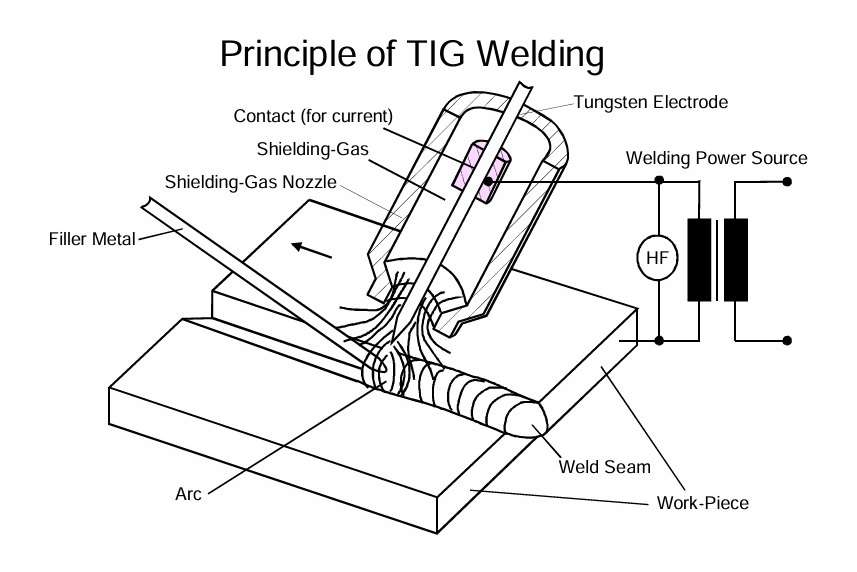

Inert-gas tungsten-arc welding (TIG) is the most widely used fusion welding process for aluminium. During TIG welding, an arc is maintained between a tungsten electrode and the workpiece in an inert atmosphere (Ar, He, or Ar-He mixture).

Depending on the weld preparation and the work-piece thickness, it is possible to work with or without a filler. The welding power source delivers direct or alternating current. A major difference between the welding of steel and the TIG welding of aluminium is the adhering oxide film on the aluminium surface which influences the welding behaviour and has to be concerned. This oxide film has to be removed in order to prevent oxides from being entrapped in the weld. The oxide film can be removed by varying the current type or polarity or also through the use of suitable inert gases.

Figure 1

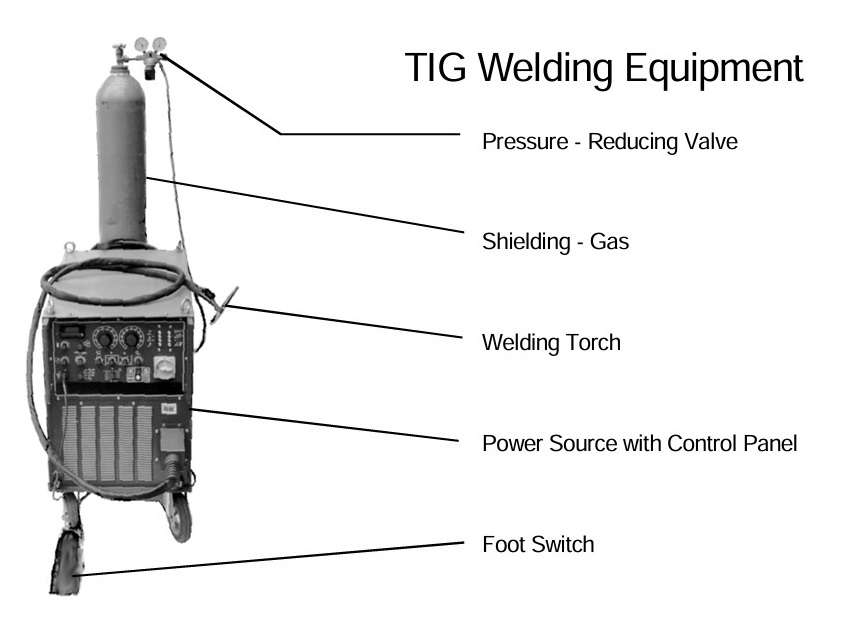

TIG welding equipment consists of the following components: Source of welding current, Torch unit with hose packet, Gas cylinders with pressure-reducing valve and flow meter. Modern welding power sources can deliver both direct and alternating current.

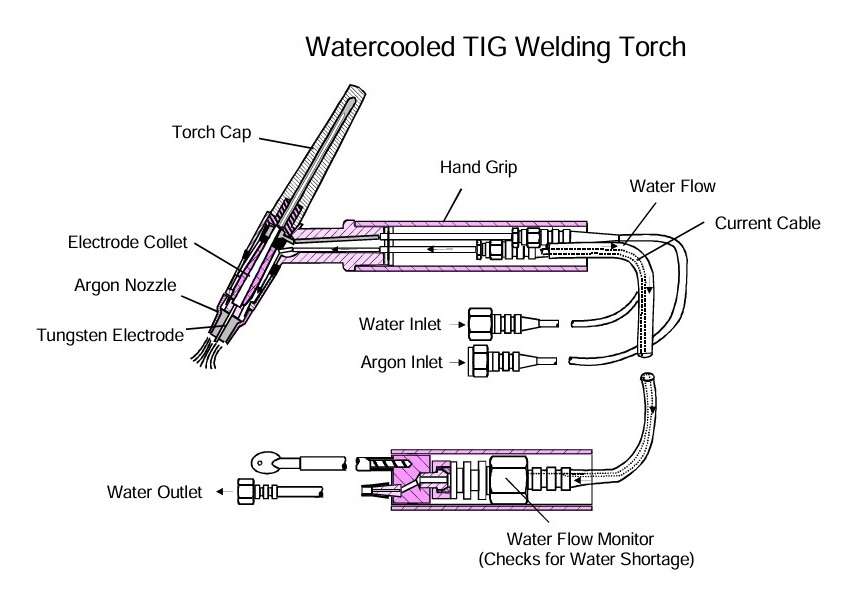

Depending on the magnitude of thermal stressing, the torches can be air or watercooled. The watercooling cools both torch and current cable. A flow meter registers any water shortage, switching off the current in this case and thus preventing torch overheating. In the region of the gas nozzle and the arc burning location, the cooling action is provided by the inert gas. The tungsten electrode has a protrusion length of 2 to 4 mm. A torch cap prevents any inadvertent contact with the electrode.

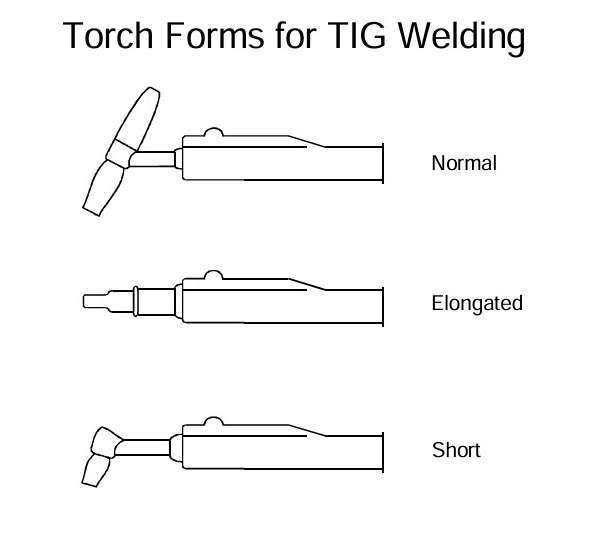

Torches of different configurations are necessary to allow for the different accessibilities of the weld seams. Welding at locations which are difficult to access can be made easier by using the short or elongated torch forms. The torch design and size also depend on the type of cooling, air or water cooled.

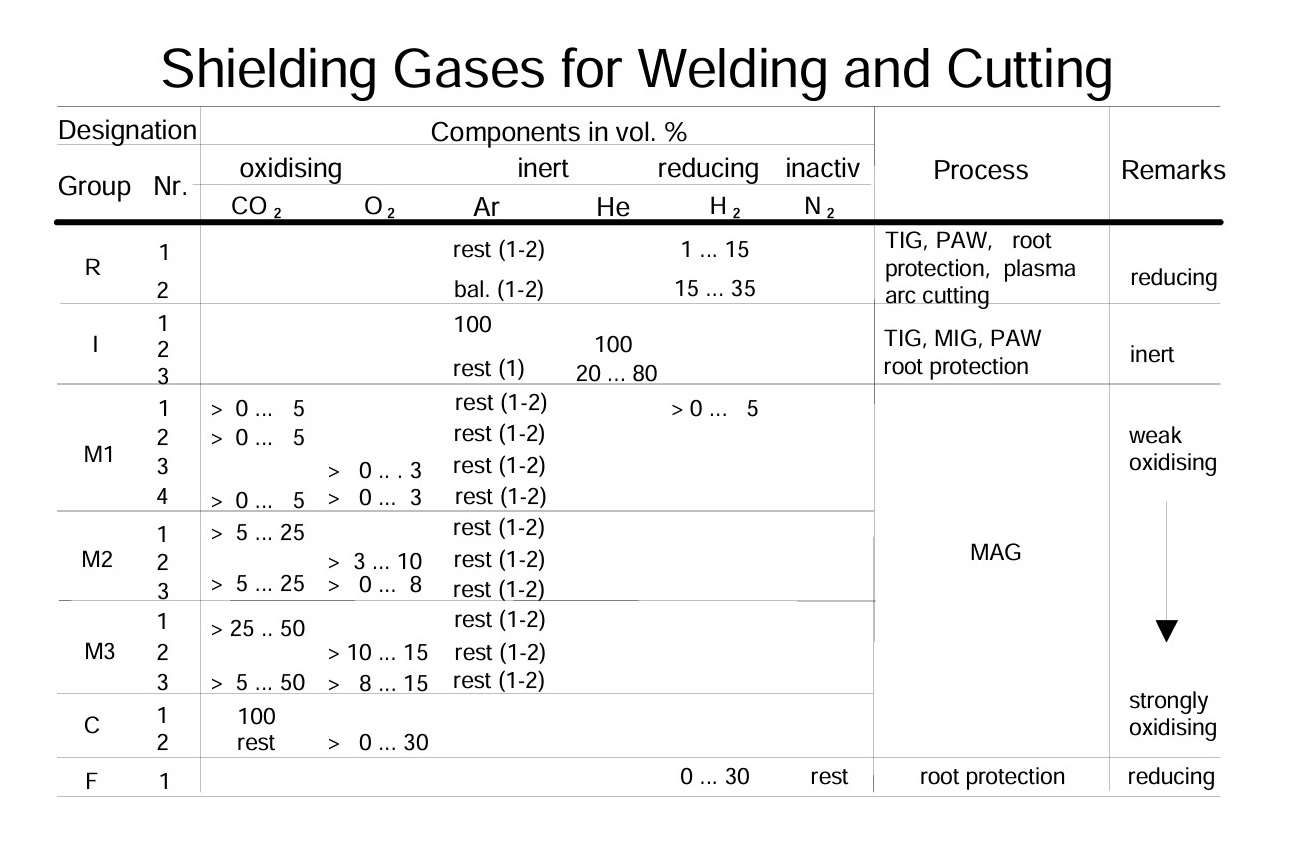

The type of shielding gas used has a major influence on the weld quality. Only inert gases and their mixtures are utilised for welding aluminium, as opposed to the welding of steel. The required purity of the gases must be guaranteed. It is most important that the limiting value for humidity is not exceeded. The gases are either delivered in compressed form in cylinders or obtained by a vaporisation process (liquefied gas) through pipe lines.

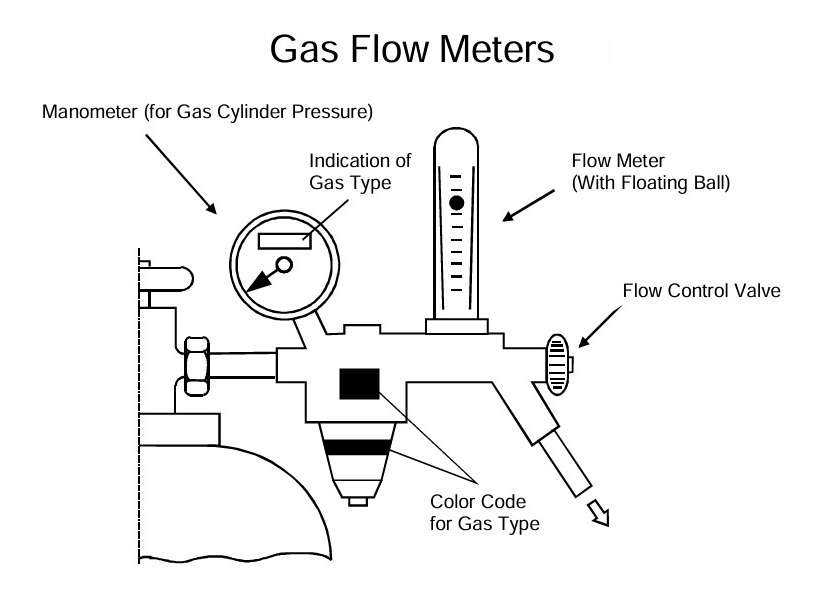

The pressure of the gas contained in cylinders is reduced by pressure-reducing valves. The amount of gas flowing in l/min is controlled via a regulating valve and indicated by the flow meter.

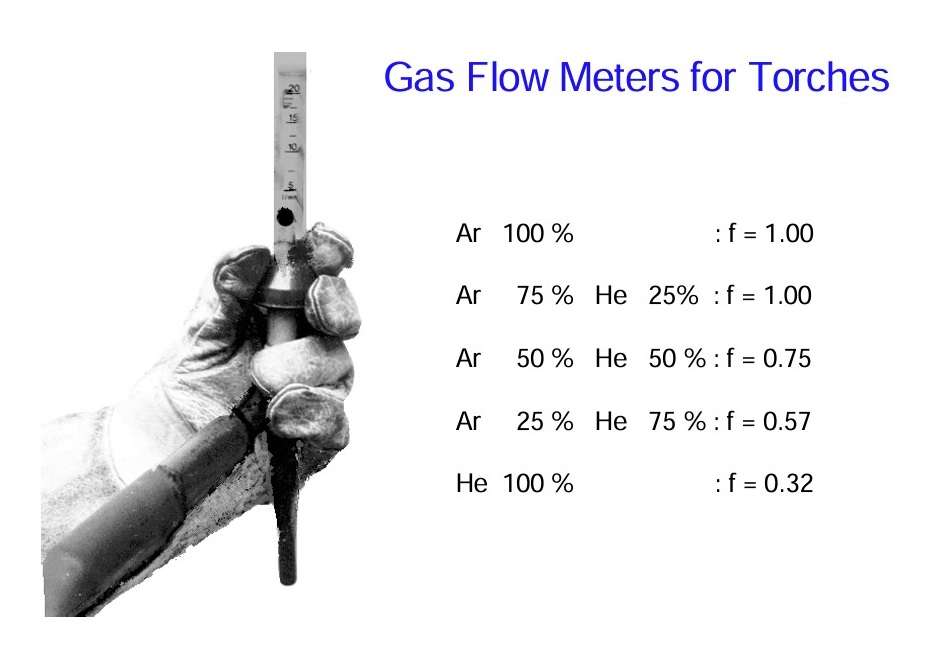

Flow meters which can be fixed directly to the torch nozzle have proved to be very practical. This shows the amount of gas actually passing through the torch in l/min. A correction factor has to be used for the varying gas densities of the Ar-He mixtures or the pure helium used.

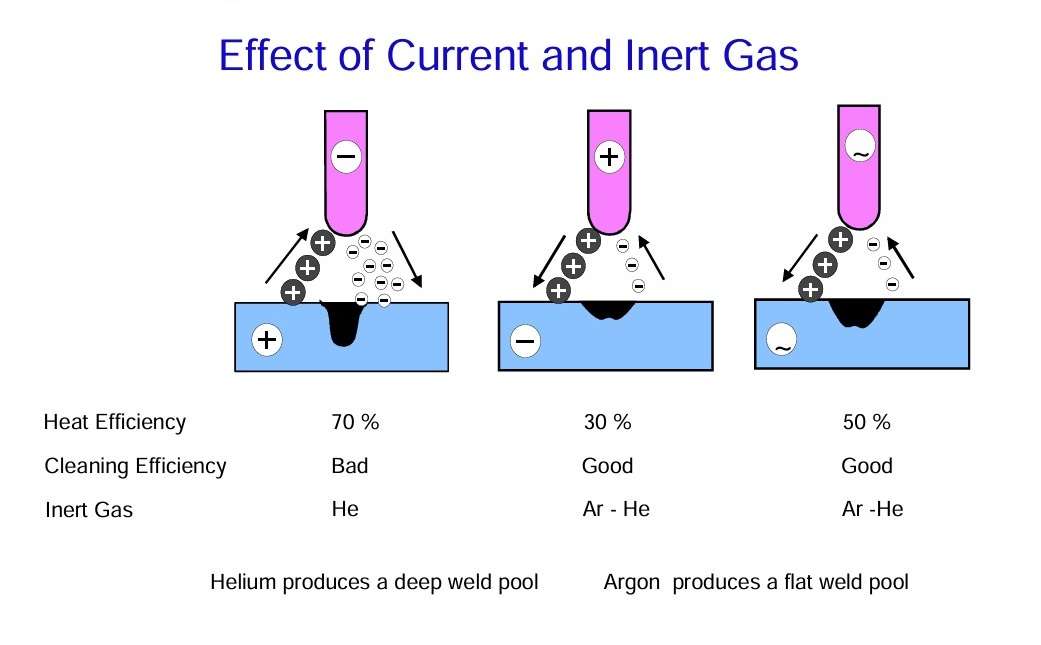

Both direct and alternating currents are used for welding aluminium. When direct-current reverse-polarity is used (electrode is positive with respect to aluminium), excessive heating of the electrode occurs, so that the electrode life is reduced or, as in some cases, even melting of the electrode end can occur. The reverse polarity (electrode positive) has a lower energy density so that the weld pool is shallower than in the case of straight polarity (electrode negative). Thus it is only used for welding thin-walled parts with low currents. However, good cooling and largediameter electrodes are necessary. The alternating-current welding is a compromise solution.

Figure 8

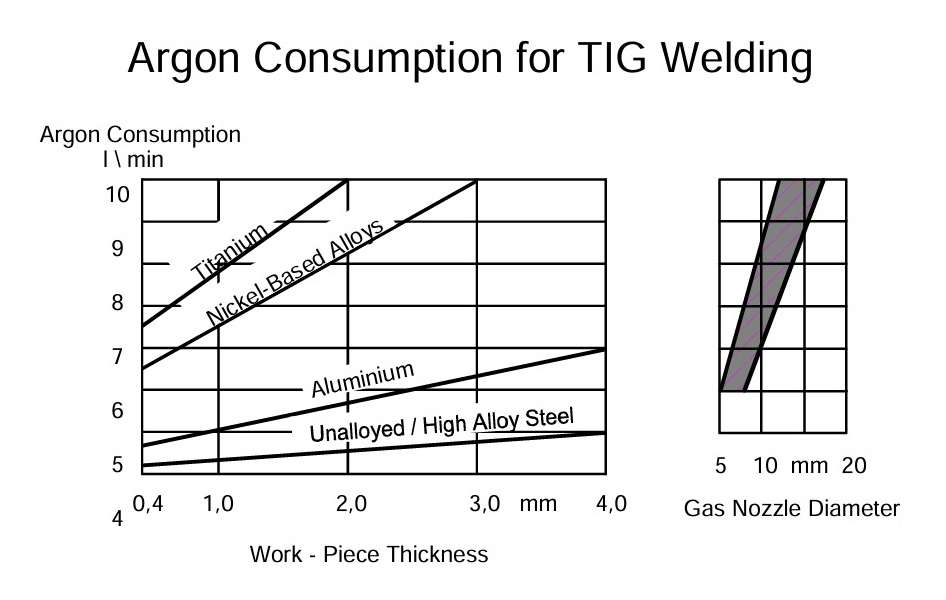

The amount of shielding gas required depends on the material used and its thickness. The gas nozzle diameter has to be optimised for the electrode diameter used. Because of its lower density, the amount of argon required is larger than the helium amount needed.

Figure 9

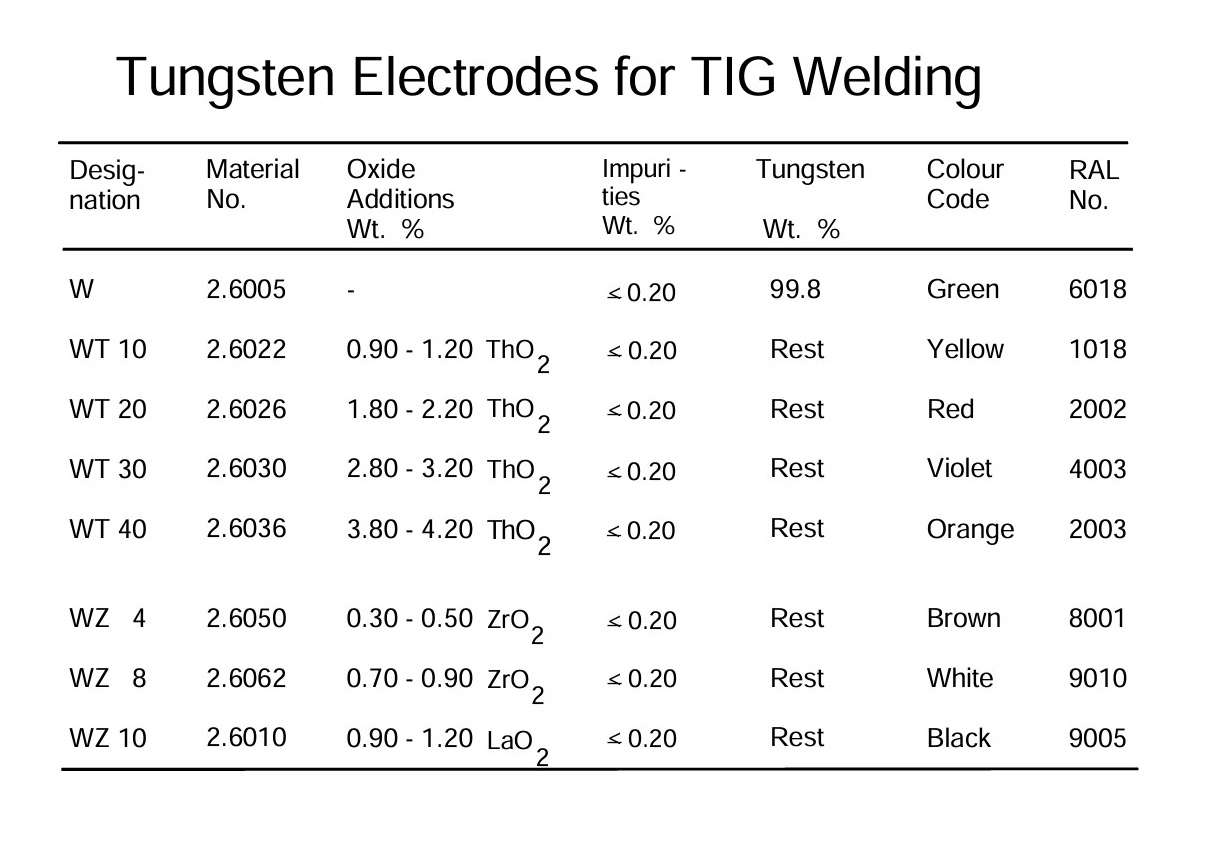

Now about Tungsten Electrodes for TIG Welding. Oxide additions (oxides of thorium, zircon, lanthan and cer) to the tungsten electrode reduce the electron emission energy. This improves: the arc stability, electrode life, current loading capacity and arc igniting properties. Thorated tungsten electrodes are most commonly used.

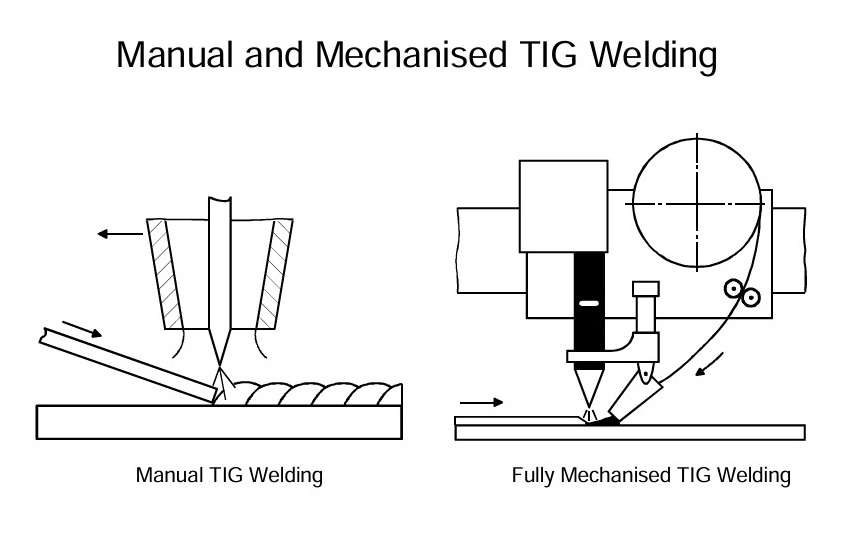

Depending on the torch manipulation and the filler metal introduction, one refers to manual welding (torch and filler metal are manipulated by hand, as in gas welding) or fully mechanised welding (torch and filler metal are manipulated mechanically).

The source:

TALAT Lecture 4201 – Arc Welding Processes: TIG, Plasma Arc, MIG / Ulrich Krüger – European Aluminium Association – 1994 .