Ten Rules for Good Aluminium Casting

Casting is a manufacturing process in which molten metal alloy is poured or otherwise caused to flow into a shape that approaches that of the finished component. In creating

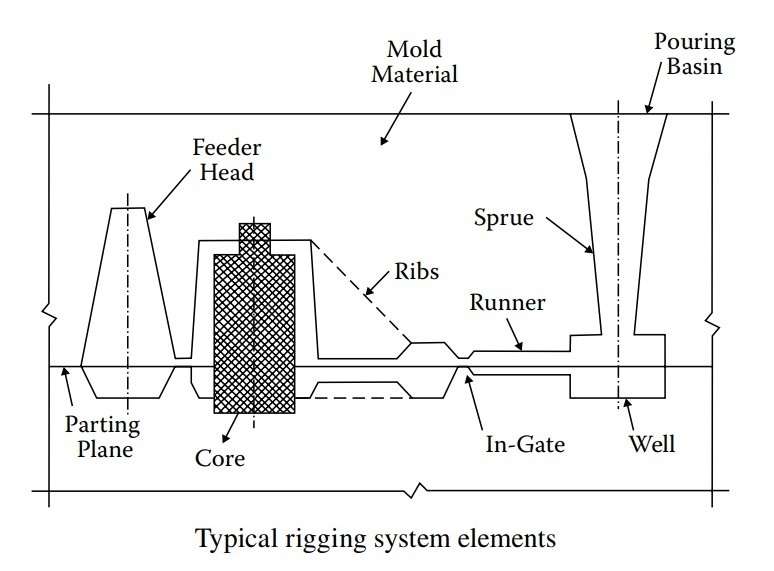

the casting, the melt is conducted to the cavity in a highly controlled manner using a system of channels, reservoirs, and other flow elements, which we will collectively refer to as the rigging system. The shape is provided by the mold, which is, in essence, a cavity having the negative shape of the component and sized to compensate for dimensional changes (shrink) that occur as the alloy solidifies and cools to room temperature.

The rigging system

Proper design of the casting system is essential. The filling function is performed by the running system, which includes the pouring cup, sprue, runners, in-gates, and other channeling and flow control elements.

The feeding system helps avoid flaws such as porosity and shrinkage cavities by locating feeders at one or more locations around the casting. Feeders (also called risers or feeder heads) are reservoirs of molten metal that continue to supply the casting with metal until it is completely solidified.

Figure 1

The Ten Casting Rules

The Ten Rules are a checklist of the fundamental requirements for the manufacture of a successful metal casting, including aluminium casting. Because of the immense complexity of the casting process, these Rules are necessary but not exclusive. Many factors are already on the known list of requirements, representing the normal preoccupations of the foundry, such as the alloy composition and its temperature. The Ten Rules are those additional fundamental requirements, many of which happen to be frequently overlooked.

Casting Rule 1

Immediately prior to casting, the melt shall be prepared, checked, and treated, if necessary, to bring it into conformance with an acceptable minimum standard. Preferably, prepare and use only near-defect-free melt.

For the dense metals and their alloys based, for example, on steel, the population of entrained defects, bubbles and bifilms, detrain quickly by flotation. Bifilms in Al alloys have nearly neutral buoyancy, taking hours or days to settle out. A good quality melt is therefore much more difficult to achieve for Al than for steel It is easy to fail the first Rule when attempting to make aluminum alloy castings.

Casting Rule 2

The liquid metal front should not go too fast The safe maximum meniscus velocity is 0,5 m/s for Al and its alloys. At this velocity, the melt has just insufficient energy to damage itself. Flow takes place quiescently. At any higher speed, the melt has enough energy to create surface turbulence, jumping sufficiently high to fold in its own surface

as it falls back under gravity.

Casting Rule 3

No part of the liquid metal front should come to a stop prior to the complete filling of the mould cavity. In other words, the liquid metal front (the meniscus) should advance continuously.

Casting Rule 4

No bubbles of air entrained by the filling system should pass through the liquid metal in the mould cavity.

Casting Rule 5

No bubbles from the outgassing of cores or molds should pass through the liquid metal in the mould cavity. Cores to be demonstrated to be of sufficiently low gas content and/

or adequately vented to prevent bubbles from core blows. Chills require to be warm and dry, and/or preferably coated with a permeable paint plus venting grooves. No use of clay-based core or mold repair paste can be allowed.

Casting Rule 6

Feed the casting to avoid solidification shrinkage problems if necessary.

Casting Rule 7

Avoid the damage caused by thermal convection during freezing. Convection in castings is not widely understood but can give serious production problems in the special cases where convection effects take place.

Casting Rule 8

Confirm macro segregation to be within limits of the specification, or agree out-of-specification compositional regions with customer. This is especially true for aluminium alloys that contain copper.

Casting Rule 9

No quenching of light alloy castings into water (cold or hot) following solution treatment. Stress well over the yield stress is generated in castings, especially those with internal cavities formed by cores.

Casting Rule 10

All castings to be provided with agreed location points for pick-up for dimensional checking and machining. The agreement on location points needs to include patternmakers (tool makers), foundry personnel, and machinists.

The sources:

1. Casting: Ten Rules for Good Casting / John Campbell // Encyclopedia of Aluminum and Its Alloys – 2019

2. Casting Design / Henry W. Stoll // Encyclopedia of Aluminum and Its Alloys – 2019