Shrinkage Porosity: A Casting Defect

Solidification defects in metal castings

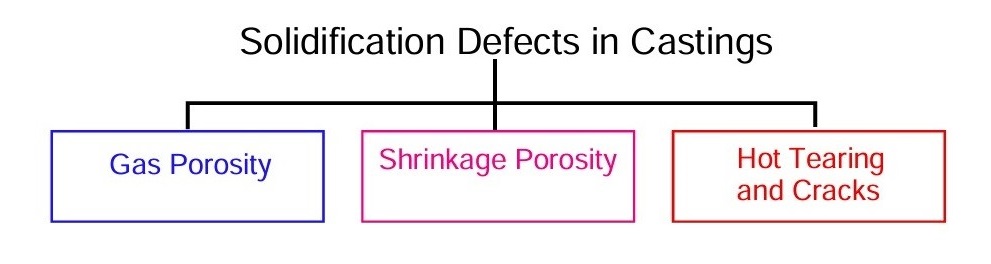

Solidification defects in metal castings can be sub-divided into three main categories:

- Gas porosity.

- Shrinkage porosity.

- Hot tearing and cracks.

In this post, we will consider the second type of solidification defects in castings – Shrinkage porosity.

Figure 1 – Solidification defects in casting

Figure 1 – Solidification defects in casting

The defect “Shrinkage porosity”

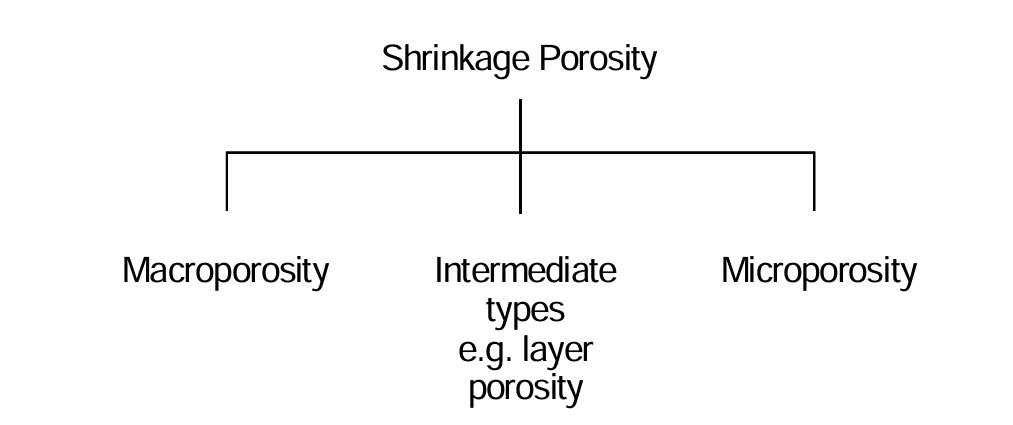

The defect “Shrinkage porosity” is conventionally sub-divided into macroporosity and microporosity. It is also possible to identify intermediate types of shrinkage porosity, notably layer porosity in long freezing range alloys.

Figure 2 – Types of shrinkage porosity

Figure 2 – Types of shrinkage porosity

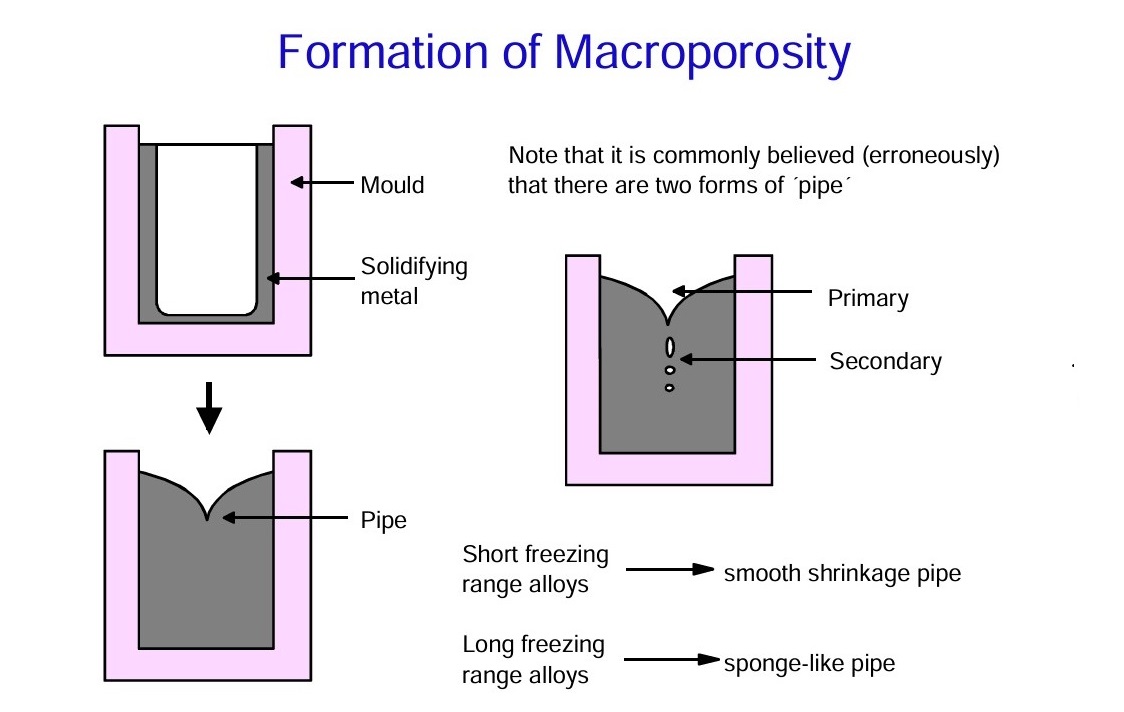

Macroporosity

The best known form of macroporosity is the ‘pipe’ formed as a simple ingot of a short freezing range alloy solidifies. Solidification starts along the walls and at a slower rate on the top surface. As progressively more metal solidifies, the volumetric contraction is compensated for by the concurrent sinking of the liquid surface, forming a smooth conical funnel or long ‘tail’ inside the ingot known as shrinkage pipe or piping.

There is a difference in appearance only between the shrinkage porosity found in short and long range freezing alloys. In a short freezing range alloy, a shrinkage cavity will take the form of a shrinkage pipe, which can have a mirror-smooth finish. In a long freezing range alloy, the shrinkage pipe takes on the character of a sponge, in which the appearance on a polished section is of separate, isolated interdendritic microporosity.

Figure 3 – Formatopn of macroporosity

Figure 3 – Formatopn of macroporosity

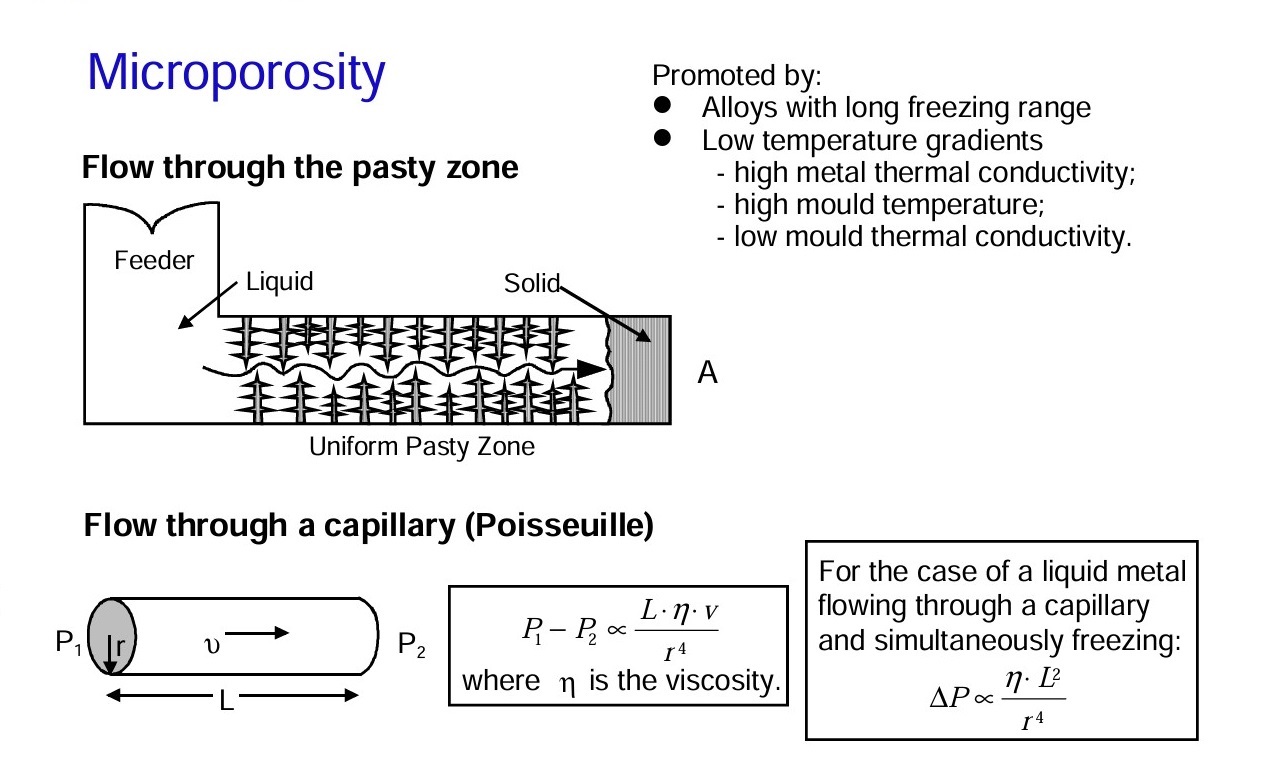

Microshrinkage porosity

This is particularly a problem in long freezing range alloys and/or when the temperature gradient is low. These conditions create an extensive and uniform pasty zone. Such a zone is favoured by:

Metals of high conductivity, such as aluminium alloys.

High mould temperatures, as in investment casting.

Thermal conductivity of the mould, as in sand, investment or plaster low moulds.

In such cases, towards the end of solidification, there will be a ‘pasty’ or ‘mushy’ zone consisting of a forest of dendrites enclosed in the remaining liquid. This figure shows a simple bar-shaped casting with a feeder at one end. At a late stage during solidification, liquid metal from the feeder will need to flow through the pasty zone to compensate for the contraction as an increasing amount of solid metal is formed at A. As the contraction tries to pull liquid metal through the pasty zone, it imposes a tensile force upon the liquid. This, without going into detail, ultimately leads to the formation of pores.

Layer porosity

Figure 5 shows a schematic view of the pressure in the liquid metal as a function of time. At time t0, everything is liquid and so there is no pressure gradient. Once solidification starts, there will be a parabolic pressure distribution through the pasty zone. As time progresses from t1 to t2, the gradual decrease in the capillary diameter will increase the tensile stress in the remaining liquid. The hydrostatic tension in the liquid in the pasty zone continues to increase until, at time t2, a critical fracture pressure Pf is reached at which a pore will nucleate.

Figure 5 – The formation of layer porosity – The begining

Figure 5 – The formation of layer porosity – The begining

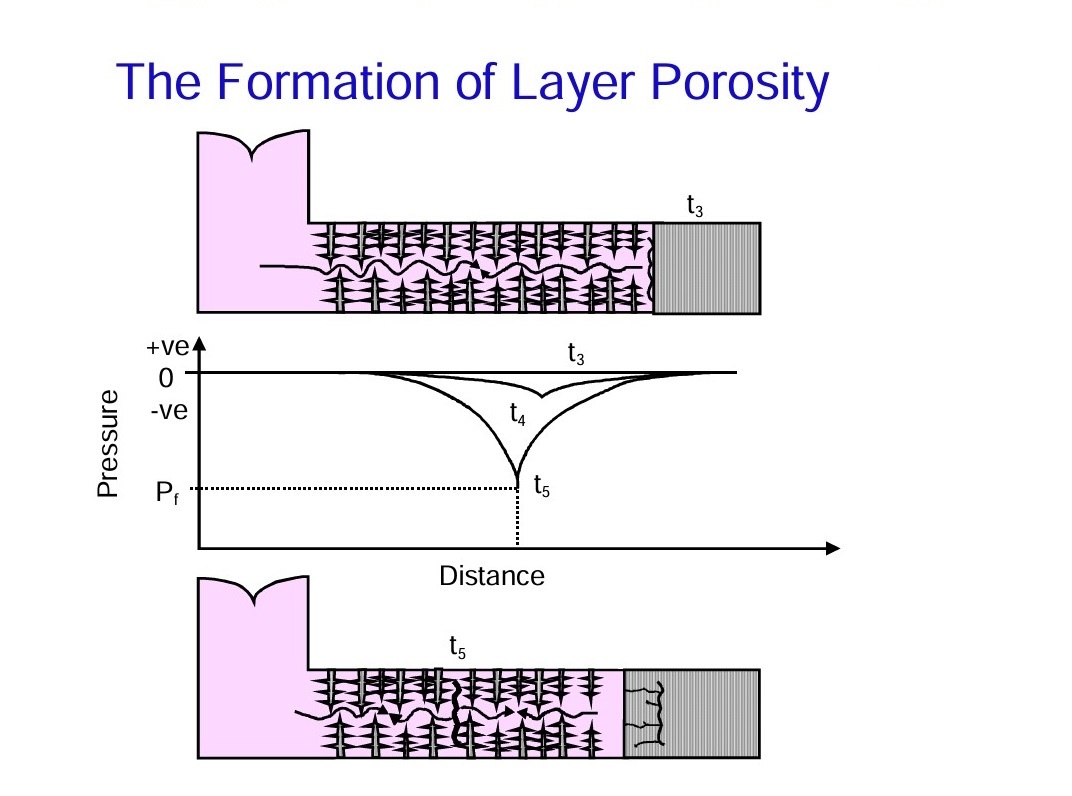

Immediately that the pore has formed, the pressure in the liquid metal is relieved and drops to zero at time t3. As solidification proceeds further, the contraction in the middle of the remaining liquid region is fed from both the feeder and by fluid from the surface of the newly created pore. Hence a parabolic pressure gradient develops from both ends (time t4) and after yet further solidification has taken place, the pressure in the liquid will again reach the critical level of Pf at time t5. A further pore will then nucleate and grow.

Figure 6 – The formation of layer porosity – The end

Figure 6 – The formation of layer porosity – The end

This process repeats until the whole of the casting has solidified. Porosity therefore occurs in a sprinkled array of fine pores, or, if the shrinkage conditions are more severe, in an array of layers. This is shown schematically here in the final casting. The dendrites tend to bridge a region of layer porosity, effectively sewing it together with closely-spaced threads. As a result, layer porosity does not have a dramatic effect on tensile strength.

The source:

TALAT Lecture 3207 – Solidification Defects in Castings / John Campbell and Richard A. Harding – European Aluminium Association – 1994