Sheet Metal Forming with Compressive Stresses

Sheet metal forming, including aluminium forming, is widely used in industry. The most rational way to classify metal sheet forming processes is to follow a stress state systems.

The main sheet metal forming groops are processes by:

- forming with compressive stresses,

- forming with combined compressive and tensile stresses,

- forming with tensile stresses,

- forming with bending, and

- forming with shear.

Predominantly compressive stresses

Now we will look at the first of these groups. To this groop belong processes where the flow in the deformation zone mainly is established by a compressive load from the surroundings. Examples are:

- Stretching.

- Dome forming.

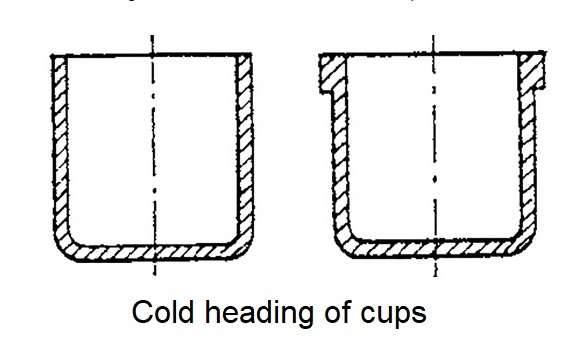

- Cold heading of cups.

- Flanging

- Coining

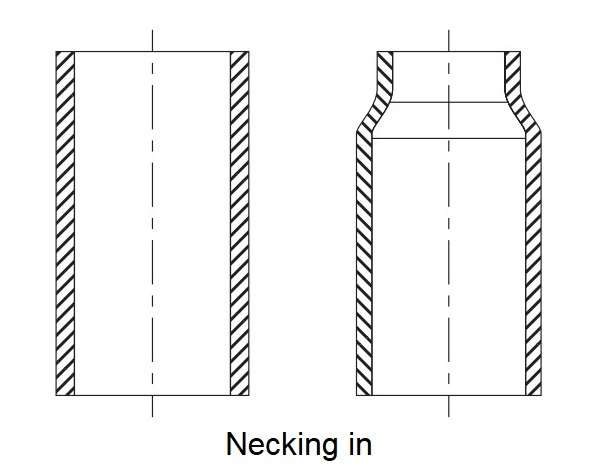

- Necking-in.

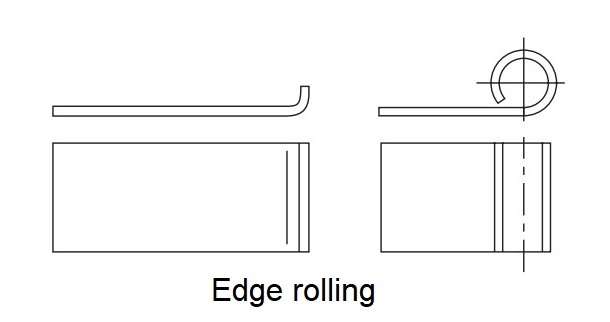

- Edge rolling.

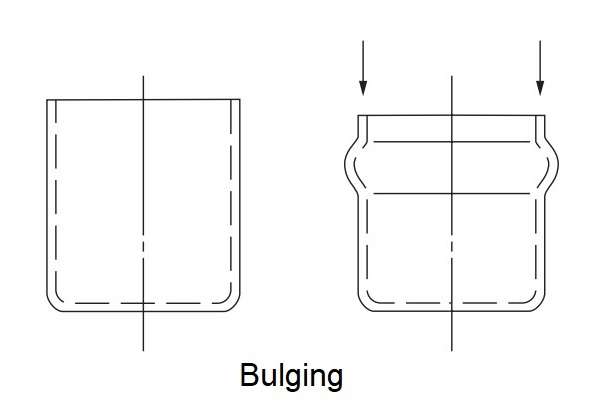

- Bulging.

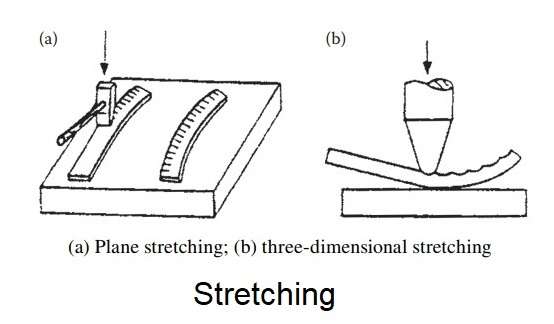

Stretching

In this process, a sheet metal work piece is shaped by stretching one of its sides by means of hammer blows or by notching with a wedge-shaped tool. The process, which is very flexible, can be carried out as well by hand as in special machinery.

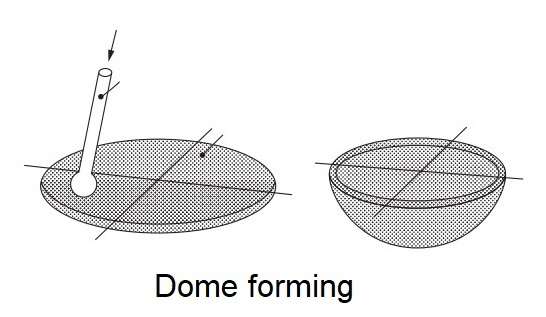

Dome Forming

In this process, a dome is formed from a sheet metal blank by local stretching made by multiple blows from a rounded hammer-shaped tool. The process, which is very flexible, can be carried out as well by hand as in special machinery.

Cold Heading of Cups

In this process, the rim of a cup is reduced in length and increased in thickness with the aid of two counteracting tools.

Figure 3 – Cold heading of cups

Figure 3 – Cold heading of cups

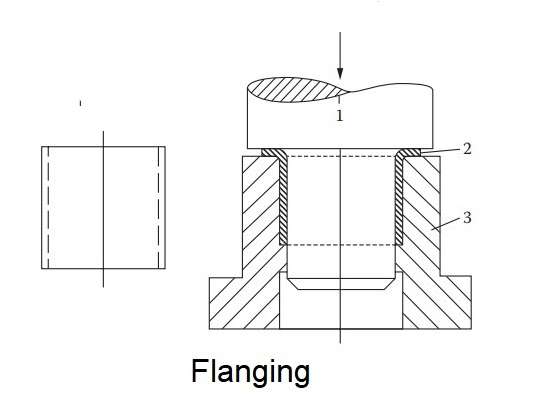

Flanging

In this process, a flange is formed on a hollow component by means of a punch and a die.

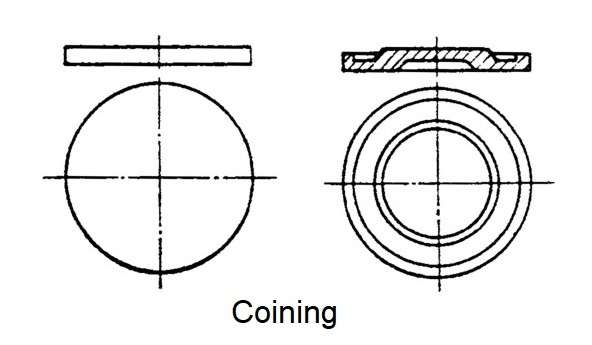

Coining

The manufacture of coins, tokens, etc , can be considered as well a sheet metal forming process as a bulk process The process takes place in special presses and highly loaded tools, often with a ring around the upper and lower coining tool, to increase the hydrostatic pressure in the process and to improve the coining precision.

Necking In

In this process, the open-end diameter of a hollow component is reduced.

Edge Rolling

In this process, the edge of a sheet or a sheet component is rolled back upon itself, usually by means of a punch and guide to give rigidity or a better appearance to an article.

Bulging

In this process, an outward channel is formed in a hollow component by the application of axial pressure to the rim of the wall.

The source:

Design of Forming Processes: Sheet Metal Forming / T. Wanheim // Encyclopedia of Aluminum and Its Alloys – 2019