Sand mold for casting aluminium

Learn about the production process and benefits of aluminium sand casting mold. Find out how this method is used to create automobile components and more.

Sand casting

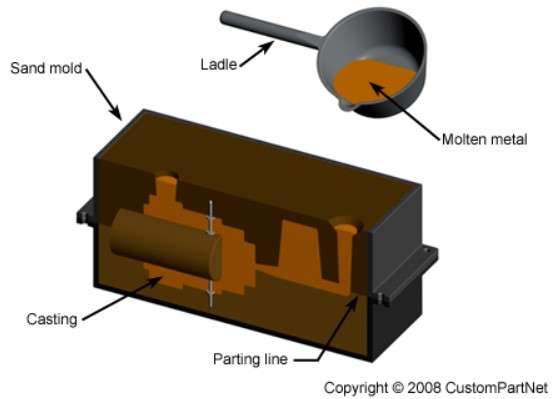

Sand casting is the most widely used aluminium casting process. It utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy, including casting aluminium alloys. Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate.

The sand casting process involves the use o (Figure 1):

- a furnace,

- metal,

- pattern,

- sand mold.

The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line and the solidified casting can be removed [1].

Aluminium sand casting is common in producing automobile components, such as engine blocks, engine manifolds, cylinder heads, and transmission cases.

Figure 1 – Sand casting process [1]

Figure 1 – Sand casting process [1]

Sand casting mold

The cope and the drag

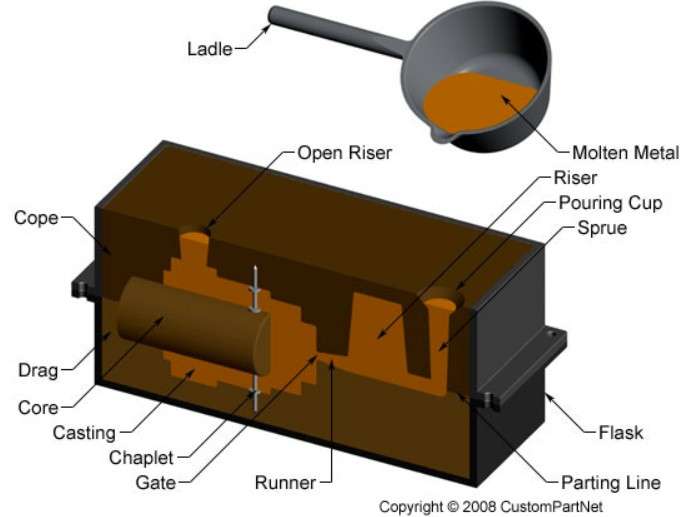

In sand casting, the primary piece of equipment is the mold. The mold is divided into two halves – the cope (upper half) and the drag (bottom half). They meet along a parting line (Figure 2).

The pattern

The mold cavity is formed by packing sand around the pattern in each half of the flask. After the sand has been packed and the pattern is removed, a cavity will remain that forms the external shape of the casting. Some internal surfaces of the casting may be formed by cores.

Cores

Cores are additional pieces that form the internal holes and passages of the casting. Cores are typically made out of sand so that they can be shaken out of the casting, rather than require the necessary geometry to slide out. Each core is positioned in the mold before the molten metal is poured.

A pouring basin

The molten metal is poured into a pouring basin, which is a large depression in the top of the sand mold. The molten metal funnels out of the bottom of this basin and down the main channel, called the sprue.

The sprue

The sprue then connects to a series of channels, called runners, which carries the molten metal into the cavity. At the end of each runner, the molten metal enters the cavity through a gate which controls the flow rate and minimizes turbulence. Often connected to the runner system are risers.

Risers

Risers are chambers that fill with molten metal, providing an additional source of metal during solidification. When the casting cools, the molten metal will shrink and additional material is needed. This strategy prevents early solidification of the molten metal and provides a source of material to compensate for shrinkage.

Venting holes

Small channels are included that run from the cavity to the exterior of the mold. These channels act as venting holes to allow gases to escape the cavity. The porosity of the sand also allows air to escape, but additional vents are sometimes needed. The molten metal that flows through all of the channels (sprue, runners, and risers) will solidify attached to the casting and must be separated from the part after it is removed.

Figure 2 – A closed casting sand mold [2]

Figure 2 – A closed casting sand mold [2]

Casting aluminium alloys

As casting materials, aluminium alloys have the following favorable characteristics [2]:

- Good fluidity for filling thin sections.

- Low melting point.

- Rapid heat transfer from the molten aluminium to the mold, providing shorter casting cycles.

- Hydrogen is the only gas with appreciable solubility in aluminium and its alloys. Hydrogen solubility in aluminium can be readily controlled by processing methods.

- Many aluminium alloys are relatively free from hot-short cracking and tearing tendencies.

- Chemical stability.

- Good as-cast surface finish with lustrous surfaces and little or no blemishes.

Sources:

- custompartnet.com

- Aluminum Shape Casting / ASM Handbook – Volume 15 – Casting – 2008 ASM International