Principles of designing a good window

In order that windows may be able to resist wind and weather expose them, windows must include in their design certain characteristics which make them sufficiently resistant to:

- rain, especially driving rain, to prevent leakage and damage caused by damp;

- wind, to prevent draughts and reduce insulation efficiency.

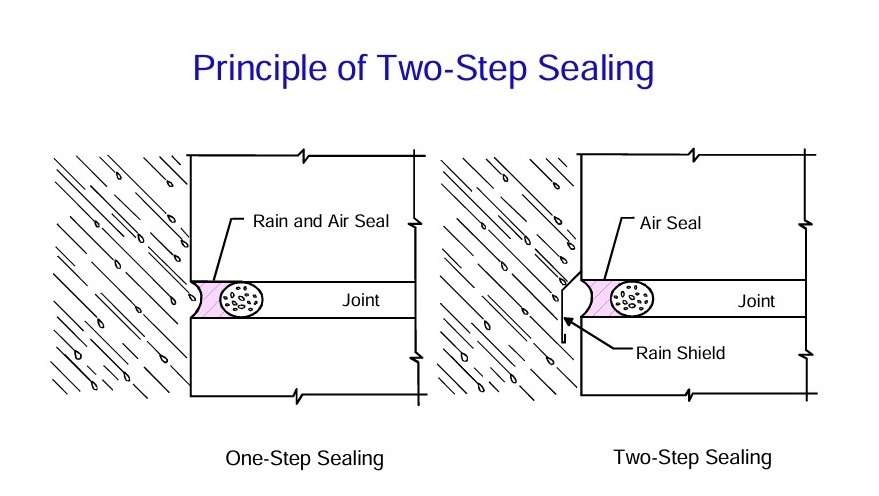

It is thus especially important for windows to be designed precisely with these factors in mind. This requires that they be built on the lines of two-stage sealing.

Two-stage sealing means that:

- The construction has an outer rain seal (first stage) and

- A separate inside wind seal (second stage).

The rain shield should prevent rain from coming into contact with the wind seal.

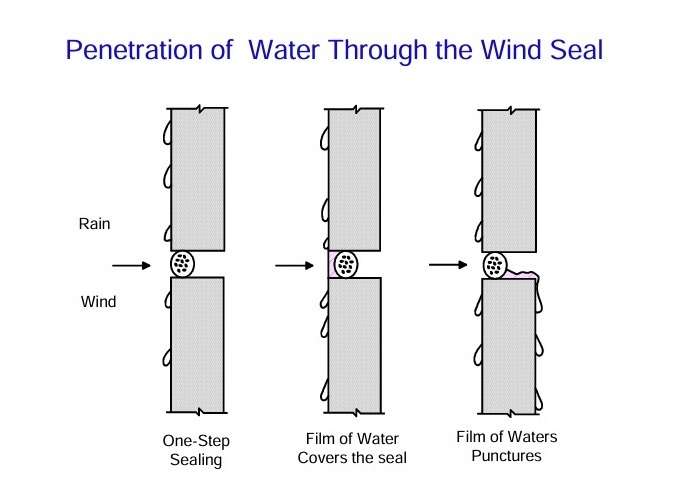

The total pressure difference between the outer and inner side of a building under wind stress will always be above the wind seal itself in the wall or windows.

Should the wind seal get wet by rain, the pressure difference will be on the film of water covering the wind seal.

This film has no strength to resist the fall in pressure and will rupture at the weakest point in the wind seal itself. Water leakage is thus almost guaranteed through the wind seal and thence towards the inside of the window. Provided the rain does not come into contact with the air seal no such leakage is likely to occur. A gap between the rain-seals and air-seals which is also drained and ventilated will form a pressure equalising chamber, hence reducing the air pressure on the wind seal.

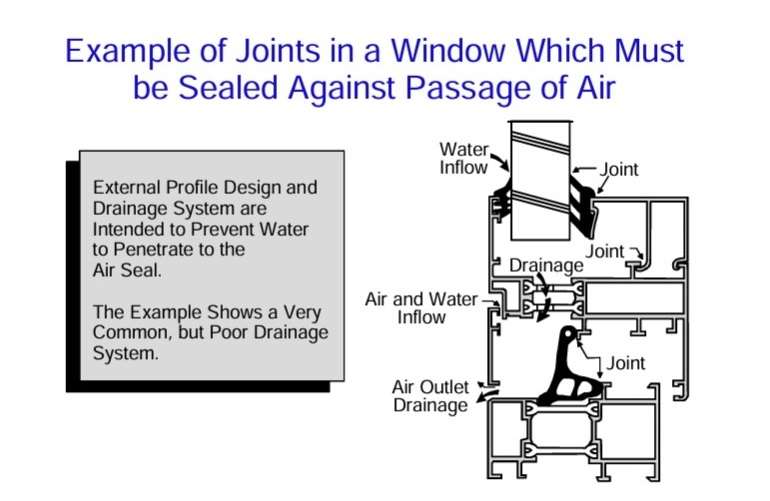

A window has several types of joints which must all be supplied with two-stage sealing. These are joints between glass and sash, joints between sash and frame, joints between glass and any crossbars, and for fixed windows, joints between glass and frame.

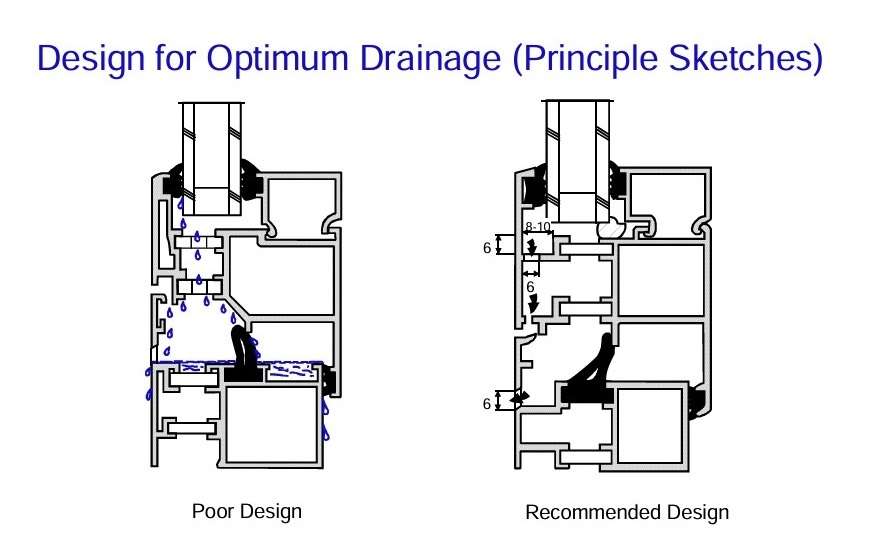

During periods of simultaneous wind and rain some water will pass the outer rain shield both between the window sash and frame and into the glass rebates. The space behind the shield must therefore be equipped with a drainage system which conducts the water out to the exterior again before it comes in contact with the air seal.

Generally speaking, the drainage system will consist of a collection channel on the sill and lower window profile, which must have a minimum dimension. Likewise the drainage holes which will conduct the water away, should have a minimum dimension.

The dimensions are determined by the size of a water drop which is approximately 4,5 millimeters in both the horizontal and vertical planes. A drainage channel or hole must therefore be larger than 4,5 millimeters such that the surface tension in the drop does not cause it to adhere to the sides of the channel or holes, and thus prevent satisfactory flow before it has built up a water level within the channel which then may push the water towards the air seal.

It is recommended, therefore, that the collection channel should have a width and height of 5 millimeters minimum and that drainage holes should also be 5 millimeters minimum in diameter. A drainage slot of for example 5 by 10 millimeters is better than a round hole.

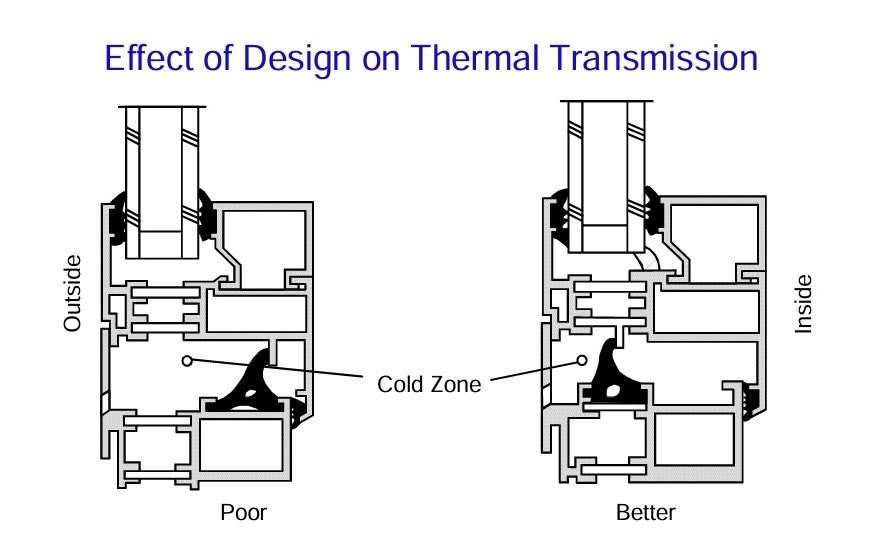

Air seals both round the glass and between the frames consist today of rubber or plastic based strips. These are fed into tracks in the aluminium profile and are placed differently dependent on the type of window. A central seal between sash and frame is most often used, as it improves the structure’s thermal characteristics at the same time by stopping outside air at the exterior part of the structure.

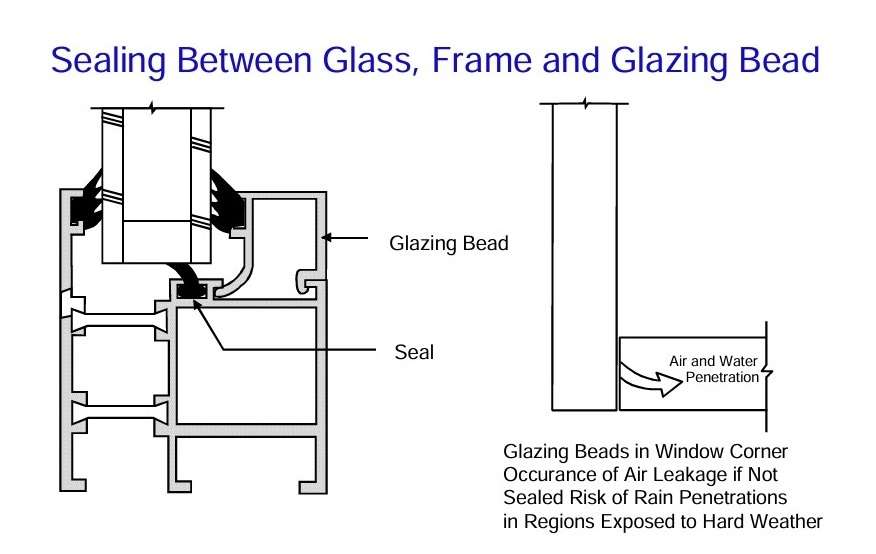

It is normally at the corners where problems arise and it is therefore vital to seal the corner joints either by gluing or welding the strips. Sealing round the glass is normally accomplished by cutting off the strips slightly overlong and pressing firmly together in all corners. This appears to be a sufficient and rational solution.

In regions which are especially exposed to wind it can be a good idea to lay in a seal in a rebate between glass and frame as aluminium windows usually have internal glazing beads which can never be completely sealed where they abut each other in the corners. The glass must thus be sealed all the way round.

Source:

TALAT Lecture 2104.02 – Building Products – Aluminium Windows / Carsten Dreier – European Aluminium Association – 1994