Pressure Counterpressure Casting of Aluminum

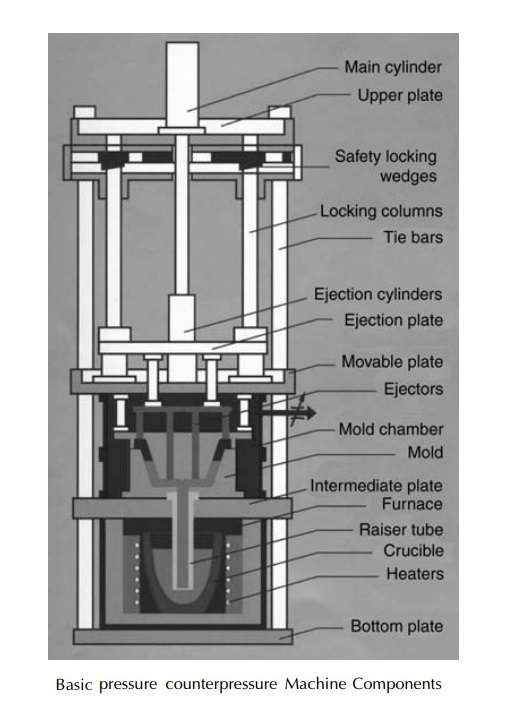

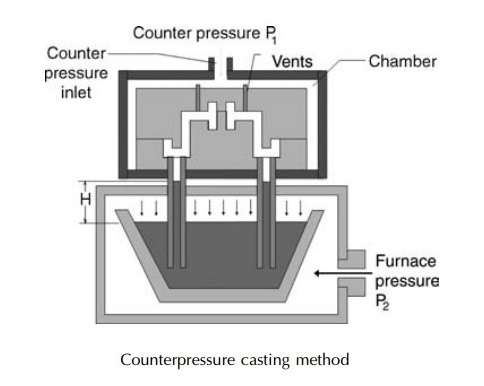

The counterpressure casting process is an evolution and extension of the basic low-pressure die casting process. The equipment used in the counterpressure casting process is similar to a low-pressure die casting machine and is essentially vertical press with a crucible furnace mounted under the press. The basic pressure counterpressure casting (PCPC) machine is shown in Figure 1. A unique feature of the PCPC process is that the horizontally parted die is surrounded by an airtight mold chamber.

The PCPC process is capable of producing high-quality, cost-effective aluminum castings if proper attention is paid to critical aspects of the process. Usually, this aluminum casting that are to be used in safety-critical automotive applications or military applications. The counterpressure castings is capable to replace aluminum forgings and squeeze castings, with significant savings to the customer.

The following describes the basic counterpressure casting cycle steps.

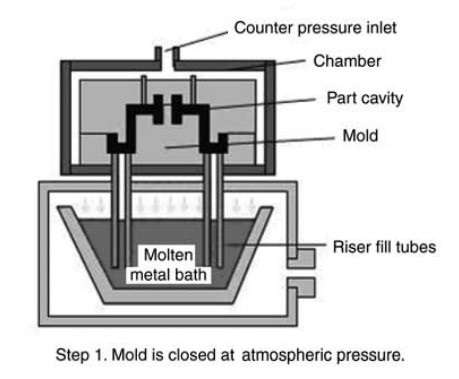

Step 1. The die closes to initiate the casting cycle. The mold chamber is set up to seal at the same time as the die halves (Figure 3).

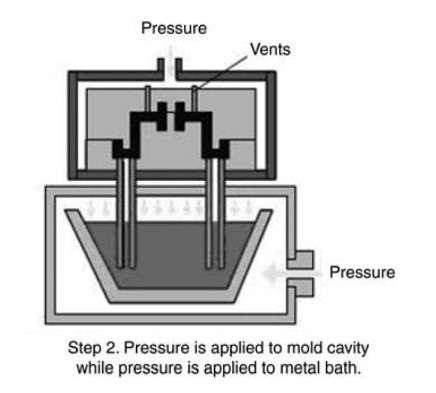

Step 2. The furnace is pressurized at the same rate as the mold chamber (Figure 4).

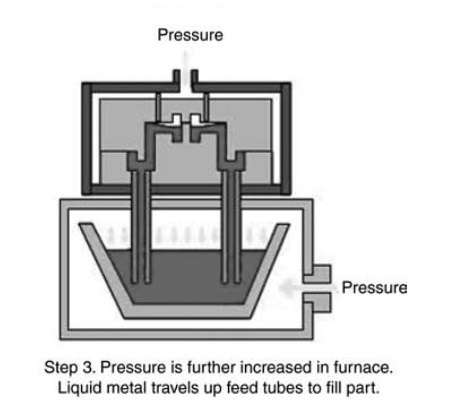

Step 3. Once the furnace pressure and the air inside the mold chamber reach the pressure set point, the pressure holds for an equalization period (Figure 5). This period is approximately 5 seconds. Then, the pressure in the furnace increases. The pressure in the chamber remains constant as it is bled off when the metal rises up the riser tubes. This pressure difference is called the delta pressure. The dellta pressure is slowly increasing to permit the die to be filled.

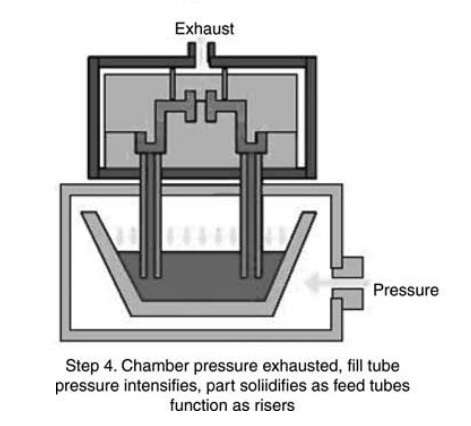

Step 4. Once the die is filled, the delta pressure is held constant for a period of time to stabilize (usually 5 seconds). Then, the pressure in the chamber is released, and the delta pressure increases by the value of the system pressure setting (Figure 6).

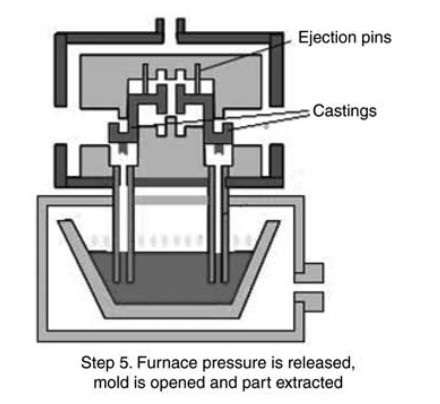

Step 5. The pressure is maintained on the furnace until the sprue has solidified (Figure 7). Once the sprue has solidified, the furnace pressure is released, and the casting cools until it has hardened enough to withstand the forces applied to it during demolding and ejection from the upper die half. The die then opens, and the casting is ejected during the mold-open phase of the casting cycle.

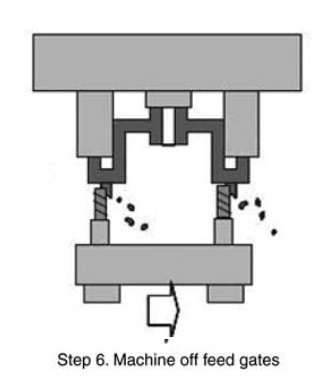

Step 6. The casting can now be processed through the remaining manufacturing process, such as degating, deflashing, inspection, heat treatment, and packaging (Figure 8).

The advantages of the PCPC process are as follows:

- High yield rate. This translates to lower operating costs, reduced melt loss, and less

material handling. - Good fill control. Fill is controlled by programmed pressure curves, and precise fill

dynamics can be achieved. - Good mechanical properties. Properties are typically better than sand and gravity permanent mold and low pressure.

The source: Low-Pressure Metal Casting /Gregory G. Woycik // ASM Handbook, Volume 15: Casting – 2008.