Plasma Arc Cutting of Aluminium

Plasma arc cutting can be used to cut metals which cannot be cut using the oxyacetylene flame cutting (e.g., Al, Cu, CrNi-steels).

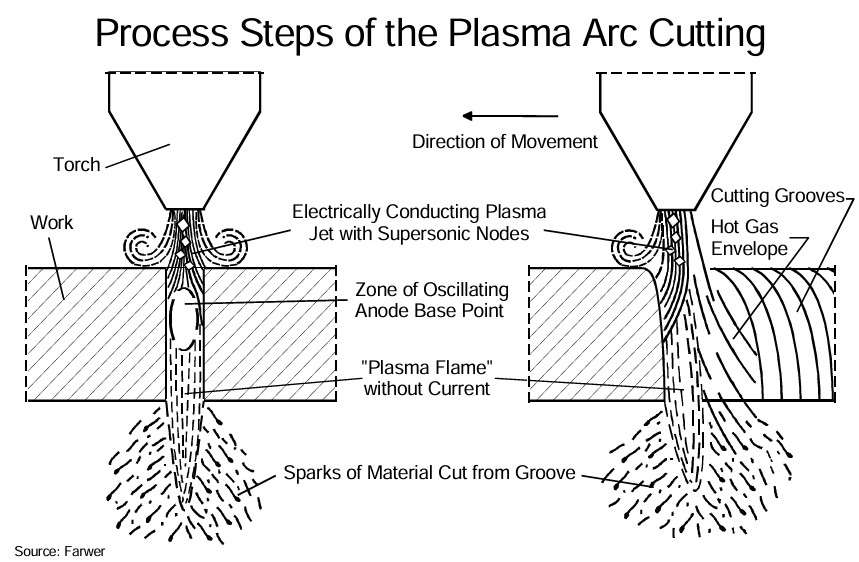

The high energy density of the restricted plasma arc and its kinetical energy is utilised in melting and blowing away the molten metal from the cutting groove. A pilot (auxiliary) arc is drawn between electrode and the gas cup, this arc being transferred to the work when the torch is brought near the work. The plasma gas is usually a mixture of argon and hydrogen in the ratio 3:2. The gas dissociates and ionises at the incandescent tungsten electrode, streaming with a high kinetical energy through the torch orifice to the work-piece. This energy is converted to heat at the work edges, causing these to melt. The moving gas stream then sweeps away the molten metal leaving a cut groove. Sheets with a maximum thickness of around 150 mm can be cut (150 kW arc power). More economical cutting solutions are possible, using variations of the process, like the water injection plasma cutting (WIPC).

Figure 1 – Process steps of the plazma cutting

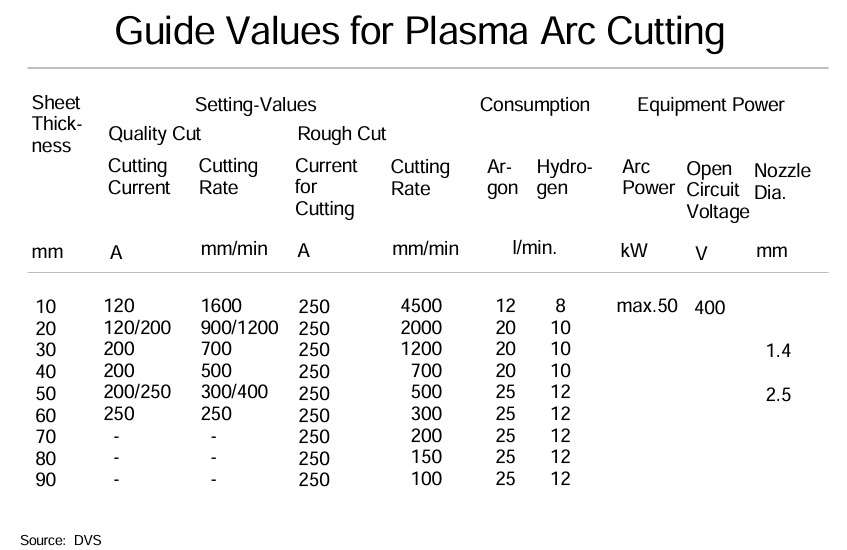

The cutting performance depends on a number of factors, so that the choice of the equipment to be employed is based especially on the economical aspects of the process. Gas costs and the environmental considerations must be considered before procuring the equipment.

Figure 2 – Guide values for plazma arc cutting

Figure 2 – Guide values for plazma arc cutting

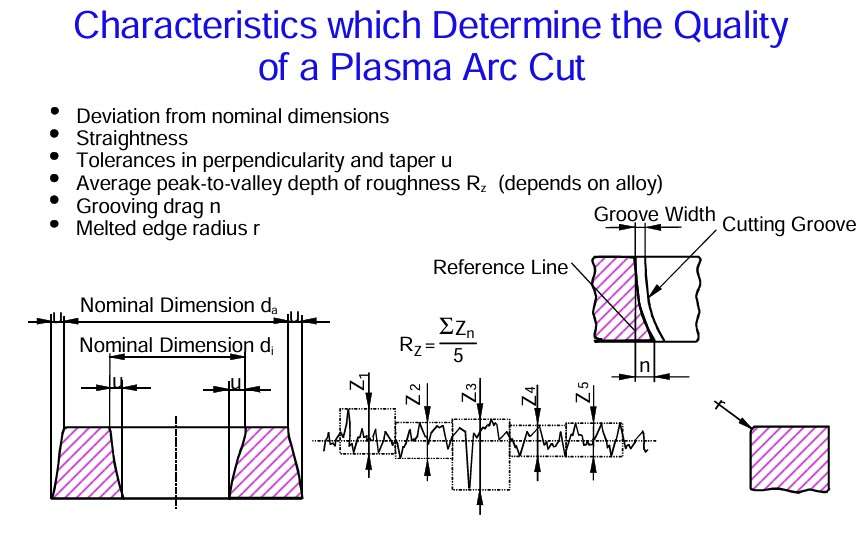

DIN 2310 part 1 lists a number of characteristics which have to be evaluated to judge the quality of cuts produced employing the gas-shielded plasma arc cutting process. One can thus differentiate between form, position and dimensional tolerance on one hand and the cut surface quality on the other.

Figure 3 – Characteristics which determinate the quality of a plazma arc cut

Figure 3 – Characteristics which determinate the quality of a plazma arc cut

The source:

TALAT Lecture 4201 – Arc Welding Processes: TIG, Plasma Arc, MIG / Ulrich Krüger – European Aluminium Association – 1994.