Permanent mold casting of aluminum

The permanent mold casting process involves the production of castings by pouring molten metal into permanent metal molds using gravity, low pressure, vacuum, or centrifugal pressure. Metals that can be cast in permanent molds include the aluminum, magnesium, zinc, and copper alloys and hypereutectic gray iron. The vast majority of permanent mold castings are made in aluminum. High-production permanent mold castings weighing up to 70 kg have been made from aluminum alloys. However, much larger castings can be produced.

A basic difference between sand casting and permanent mold casting is the metal molds for the latter process. These metal molds are usually made of iron or steel and have a production life of 10,000 to 120,000 or more castings as opposed to sand casting, which requires a new mold for each casting produced.

Figure 1 – Examples of aluminium permanent mold castings

Figure 1 – Examples of aluminium permanent mold castings

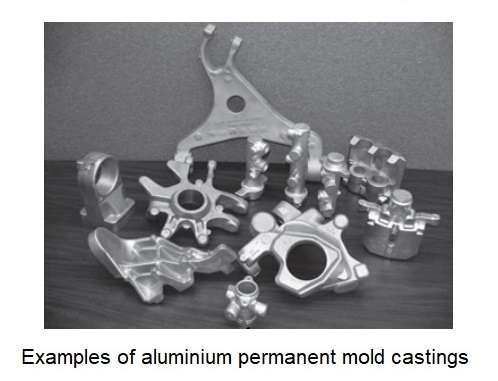

Manually operated permanent molds for low production may consist of a simple book-type mold arrangement (Figure 2).

Figure 2 – Simple book-type mold for shallow-cavity casting

Figure 2 – Simple book-type mold for shallow-cavity casting

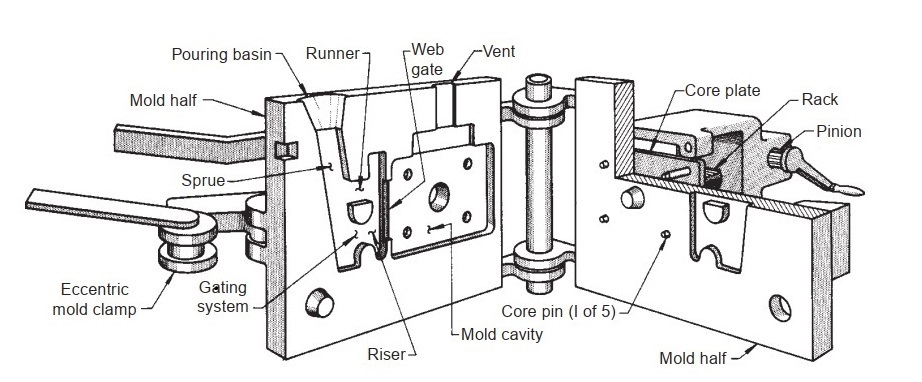

For castings with high ribs or walls that require mold retraction without rotation, the manually operated device shown in this figure can be used (Figure 3). With either type of device, the mold halves are separated manually after releasing the eccentric mold clamps.

Figure 3 – Device for deep-cavity molds

Figure 3 – Device for deep-cavity molds

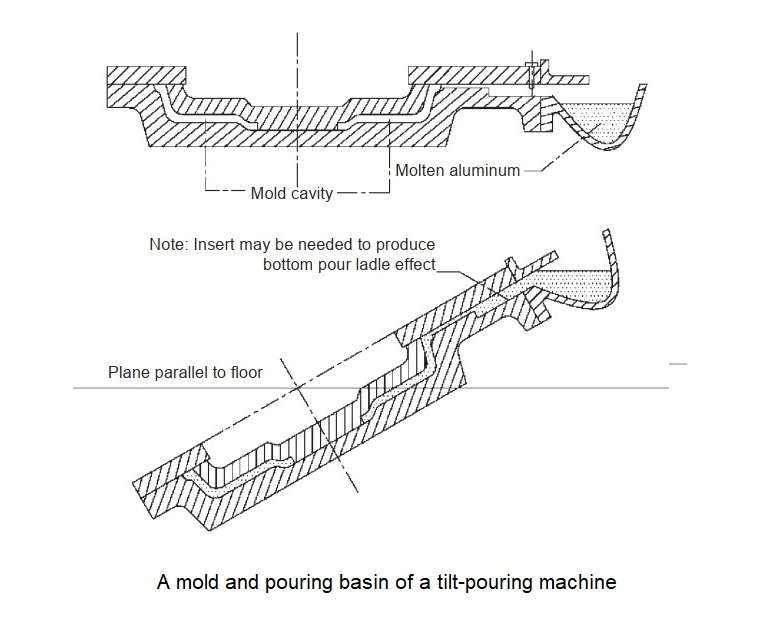

Often the mold parting for the static casting devices is in a vertical plane. Many castings, however, benefit greatly from tilt pouring, which provides significant advantages over statically poured castings in a vertical plane as it shown in Figure 4. Tilt pouring offers advantages in less pouring turbulence, more consistent filling speeds, less reliance on operator skills, and it facilitates full automation.

Figure 4 – A tilt-pouring machine

Figure 4 – A tilt-pouring machine

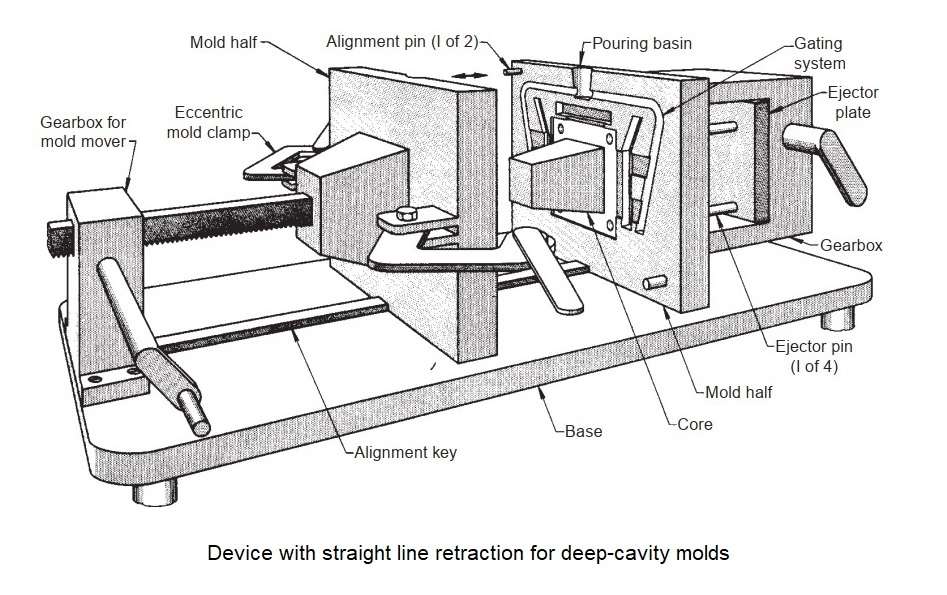

Only the most simple permanent mold castings can be ejected from the mold with no mechanical help. Most castings are ejected by well-distributed ejector pins or are confined in one mold half during opening of the mold and then ejected by the withdrawal of the retaining core or cores. It is important that the casting remain in the correct mold half until ready for ejection. Figure 5 illustrates a typical tilt pour, permanent mold rigging system.

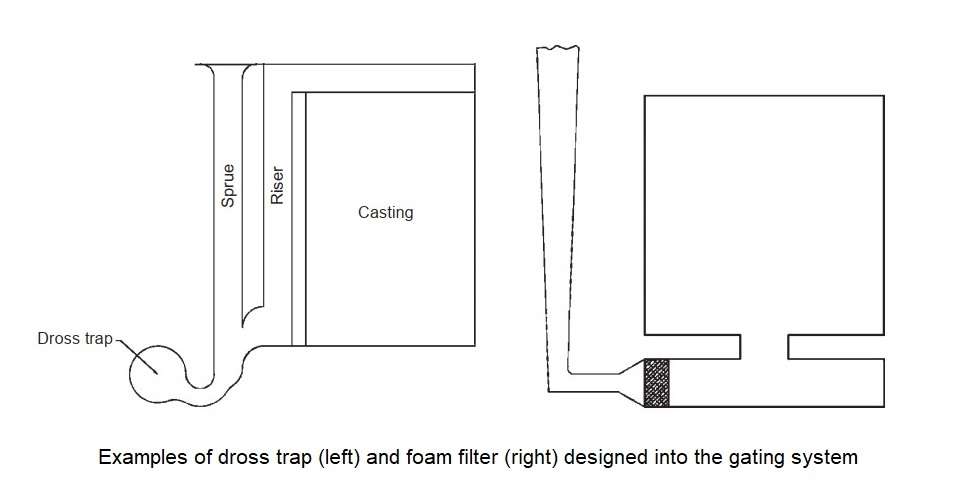

To avoid oxide contamination, it may be necessary to incorporate dross traps or filters into the gating system (Figure 6). Perforated steel screens or woven fiberglass have been commonly used for filtration and reduction of metal velocity. However, reticulated ceramic foam filters have proven to be much more effective in not only entrapping potential inclusions but also in reducing metal velocity and pouring turbulence.

Figure 6 – Examples of filters in the gating system

Figure 6 – Examples of filters in the gating system

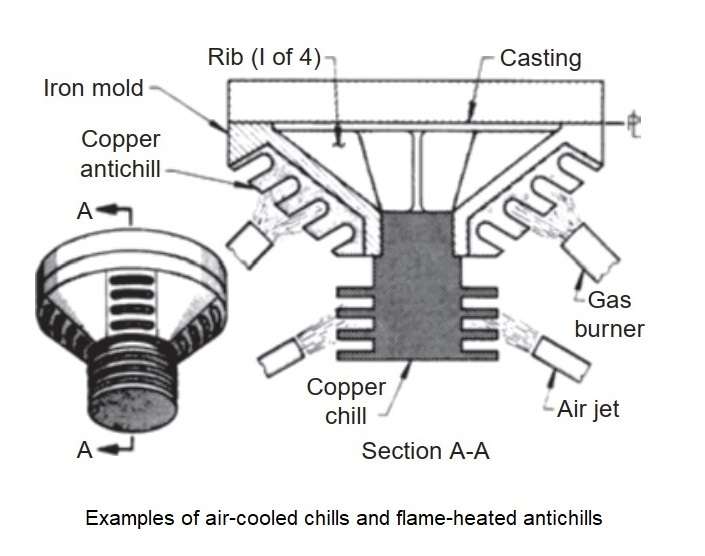

Optimal mold temperature is the temperature that will produce a sound casting in the shortest time. For an established process cycle, temperature control is largely achieved through the use of auxiliary cooling or heating, control of coating thickness, and cycle-time consistency. Auxiliary cooling is often achieved by forcing air or water through passages in mold sections adjacent to the heavy sections of the casting (Figure 7).

Figure 7 – Examples chills and antichills

Figure 7 – Examples chills and antichills

The source:

Permanent Mold Casting / Don Tyler // ASM Handbook, Volume 15: Casting – 2008.