MIG Welding of Aluminium

MIG Welding is Metal Inert Gas Welding

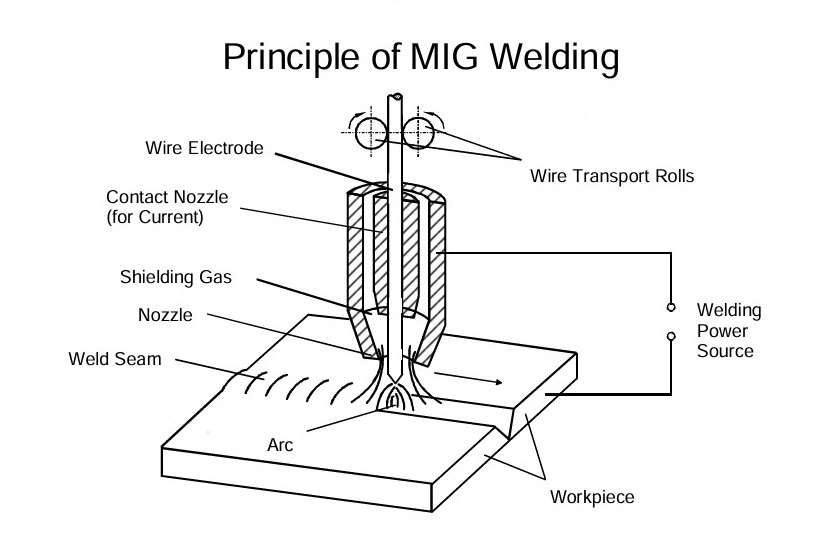

Analogous to TIG welding, MIG welding is conducted using inert gases. The arc is drawn between the melting wire electrode and the work. The current to the positively poled wire is supplied through a contact nozzle (tip). Here it is possible to work with high current densities (more 100 A/mm2). In comparison, the current densities used for TIG welding with alternating current lie around 20 to 30 A/mm2. The melting power of MIG welding is thus very much higher than with the TIG process. Contact nozzle and the relatively short wire end are surrounded by inert gas. This gas serves to protect the melt pool, wire and arc as well as to cool the contact nozzle. The filler wire (0.8 to 2.0 mm diameter) is delivered as rolls and fed to the welding zone with the help of wire feed rolls.

Manual MIG Welding

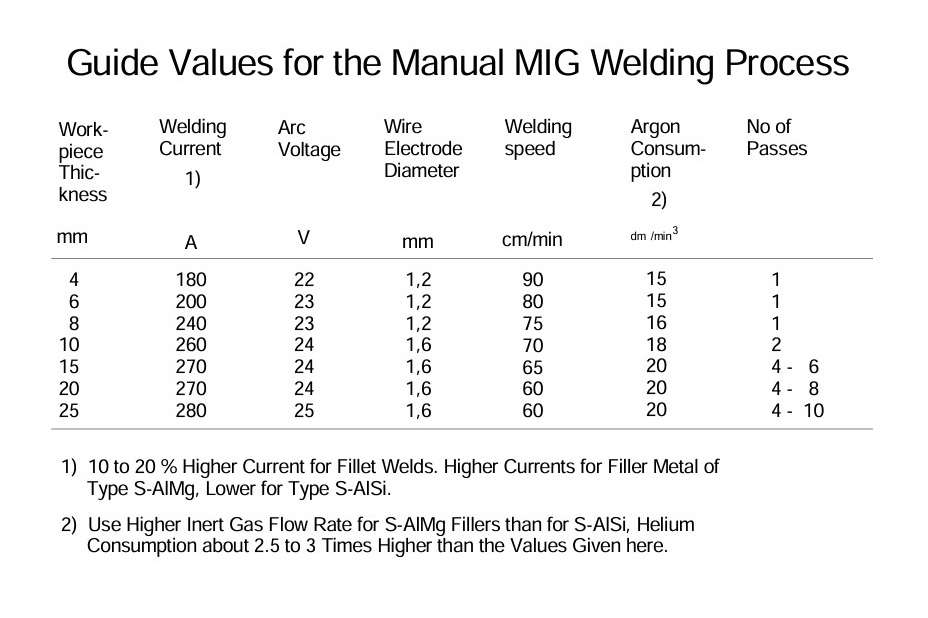

Manual MIG welding is usually carried out in the lower power levels (less 400 A) because of the weld pool size, arc radiation and the heat developed. Wire diameters of up to 1.6 mm are used. At higher power levels, fully mechanised or automatic equipment is employed.

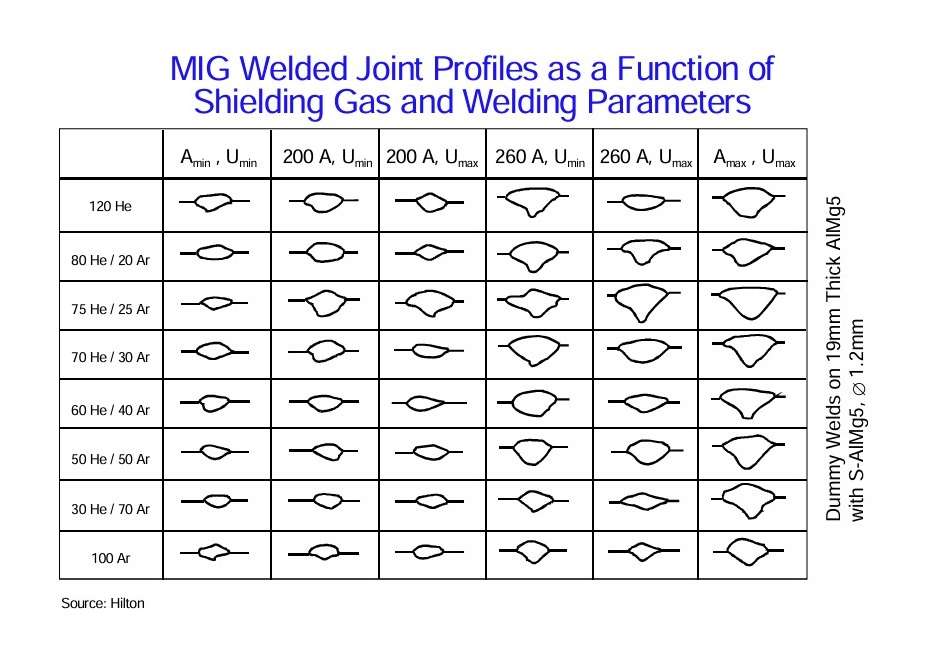

MIG Welded Joint Profiles

The penetration during the welding of aluminium depends not only on the current and voltage but also on the composition of the shielding-gas used. This is illustrated in this figure for welds on AlMg5 using a filler wire of the same composition. The most unfavourable conditions occur when pure argon gas is used.

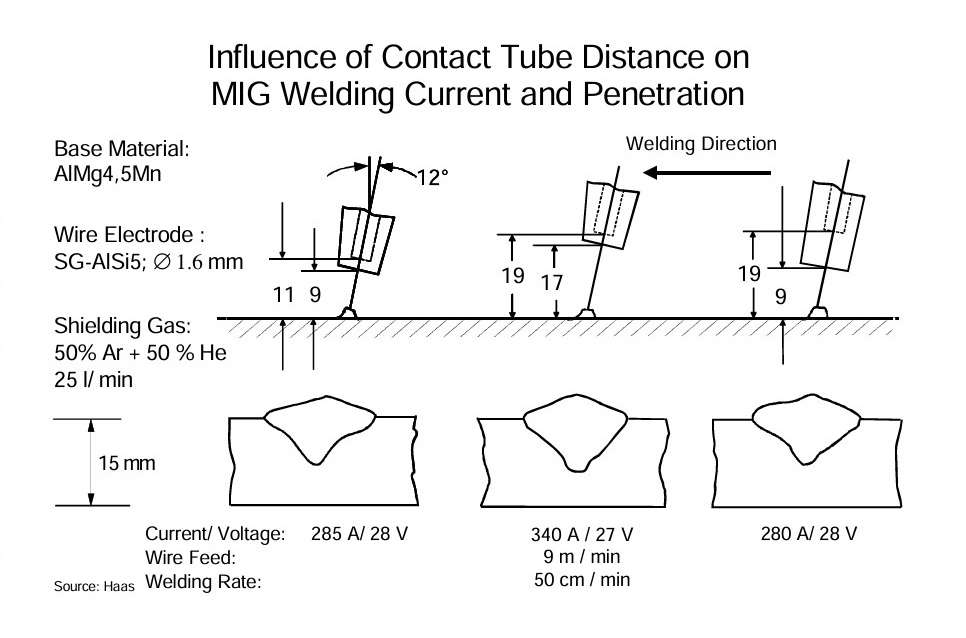

During steel welding, the penetration and current decrease with increasing contact tube distance.

The MIG welding of aluminium shows an opposite behaviour, i.e., current and penetration increase with increasing contact tube distance. The reason for this diverging behaviour is the different energy conditions existing in the steel and aluminium arcs.

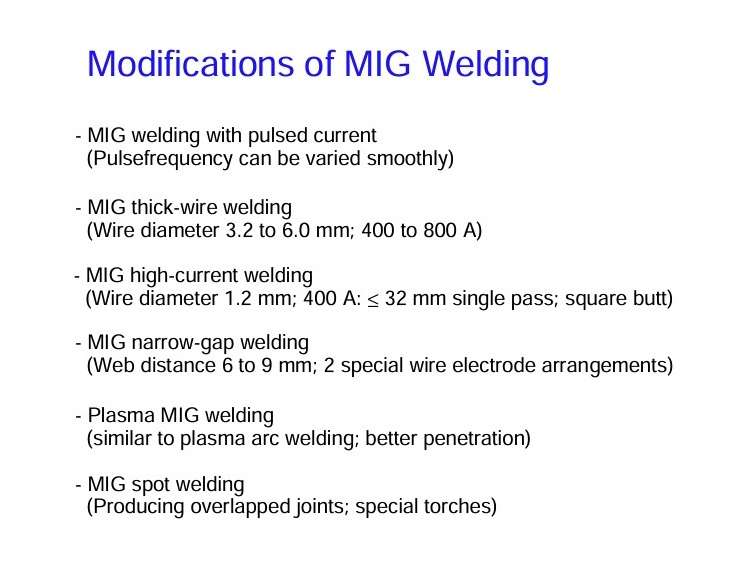

Modifications of MIG Welding

A number of modifications to the MIG welding process have made it possible to diversify the fields of application for this welding process.

- Pulsed welding which has a number of advantages is most widely spread: − a short-circuit-free transfer to the material is possible even for thin sheets (< 4 mm). − stable arc − degassing is easier in a pulsing bath (lower porosity) − thicker wires, which have the advantage of a lower ratio of oxidised surface to wire volume, can be used to replace thinner wires.

- In thick-wire welding it is possible to employ higher currents.

- In high-current welding, thin wires are melted using high current densities.

- In narrow-gap welding, thick sheets can be welded without any edge preparation. Because of the narrowness of the gap, less filler metal is required. This leads to a decreased heat development with relatively low distortion.

- The plasma-MIG welding is a process combination in which a plasma arc and a MIG arc are established simultaneously.

- In MIG spot welding, overlapping sheets are melted in local spots.

The source:

TALAT Lecture 4201 – Arc Welding Processes: TIG, Plasma Arc, MIG / Ulrich Krüger – European Aluminium Association – 1994.