Special Mechanical Joints for Aluminium Profiles

Well designed joints are essential to ensure the satisfactory performances of any structure. Here we present mechanical connections of extruded profiles to each other without the use of bolts, rivets and welding. Only due to the clever design of the profiles! These compounds include:

- Profile to Profile Joints

- Snap Joints

- Corner Connections.

Profile to Profile Joints

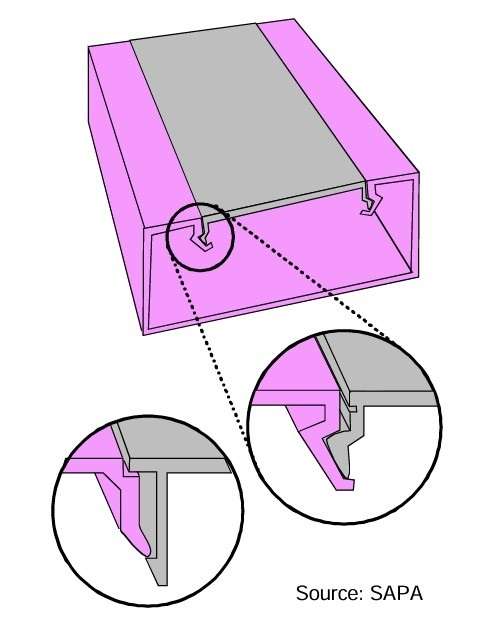

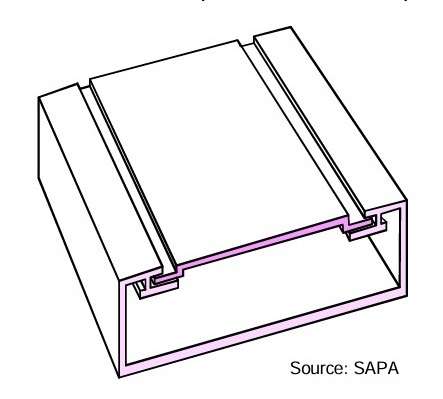

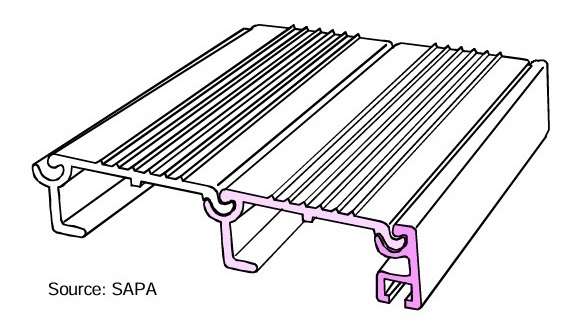

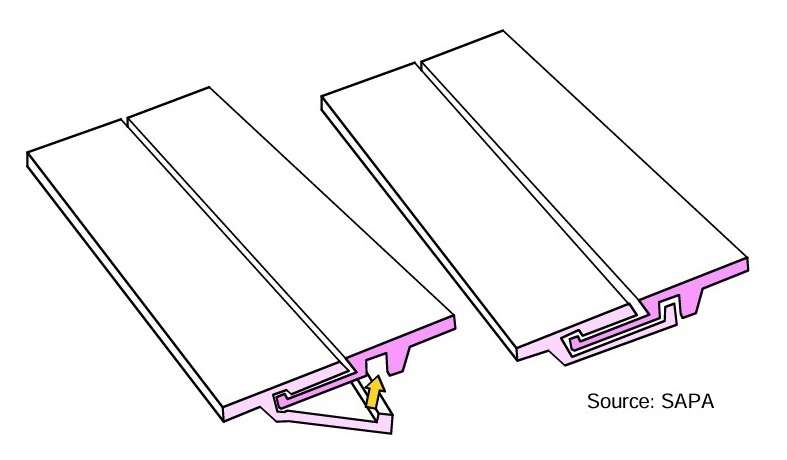

It is often an advantage to design products with large cross sections, such as component boxes, panels etc., as built up of smaller profiles. Figure 1 shows one simple way of connecting two profiles in the longitudinal direction is by including a groove and tongue in the cross section so the profiles may be pressed together.

Figure 1 – A simple way of connecting two profiles in the longitudinal direction

Figure 1 – A simple way of connecting two profiles in the longitudinal direction

Locking the profiles in the longitudinal direction is possible by use of lock screws, plasic deformation (such as hammer blow), or by screws at the ends.

Figure 2 – Locking the profiles in the longitudinal direction

Figure 2 – Locking the profiles in the longitudinal direction

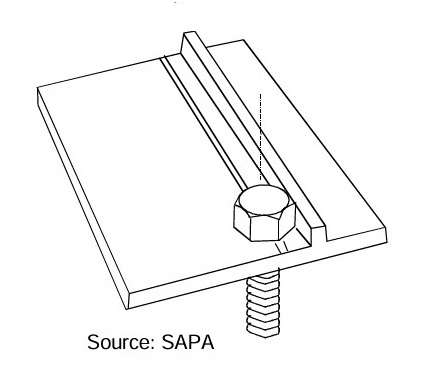

Figure 3 shows a design where connection grooves can also be used for washers or bolt heads.

Figure 3 – A design with connection groovs, which can be used for washers or bolt heads

Figure 3 – A design with connection groovs, which can be used for washers or bolt heads

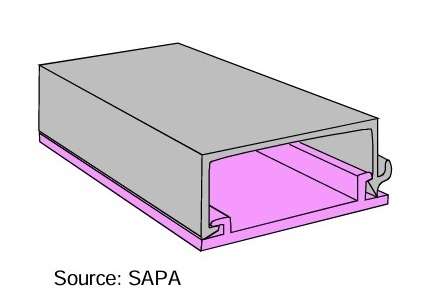

In this case the two profiles constitute a socket which is used for locking the parts and for mounting an ending fitting (Figure 4).

Figure 4 – The two profiles constitute a socket for locking the parts and for mounting an ending fitting

Figure 4 – The two profiles constitute a socket for locking the parts and for mounting an ending fitting

Figure 5 shows, that joining is also possible by using a separate smaller profile that is cut into short lengths and used for locking.

Figure 5 – Joining by using a separate small profile

Figure 5 – Joining by using a separate small profile

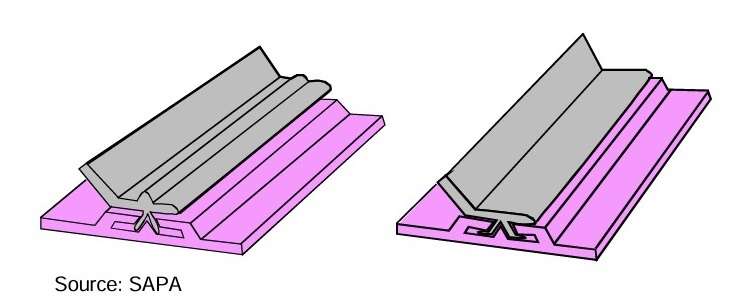

This connecting method takes advantage of the workability of aluminium (Figure 6). Two profiles is locked together by pressing intermittently or along the entire length. This gives a permanent connection.

Figure 6 – Two profiles is locked together by pressing intermittently or along the entire length

Figure 6 – Two profiles is locked together by pressing intermittently or along the entire length

Figure 7 shows a connection when two aluminium profiles rolled together.

Figure 7 – A connection when two aluminium profiles rolled together

Figure 7 – A connection when two aluminium profiles rolled together

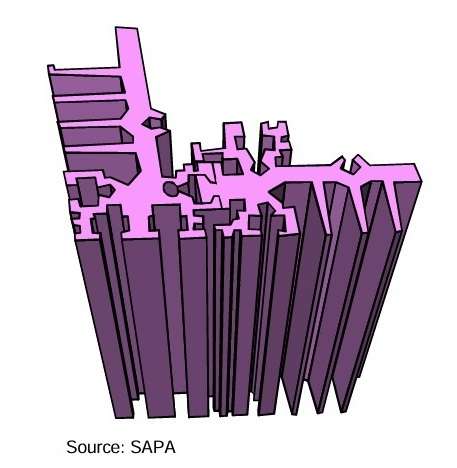

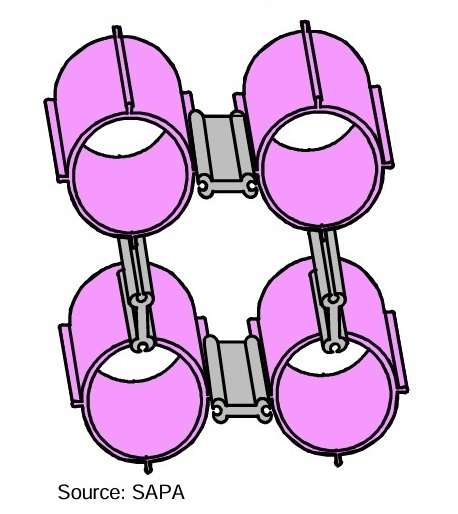

Several decorative elements connected together with separate parts (Figure 8).

Figure 8 – Several decorative elements connected together with separate parts

Figure 8 – Several decorative elements connected together with separate parts

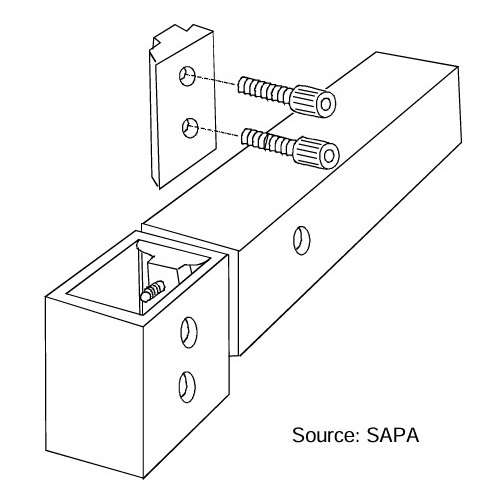

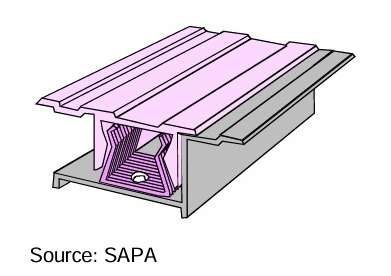

Figure 9 shows how material is saved by using a separate profile, cut into smaller lengths, as reinforcement for screws.

Figure 9 – Using a separate profile, cut into smaller length, as reinforcement for screws

Figure 9 – Using a separate profile, cut into smaller length, as reinforcement for screws

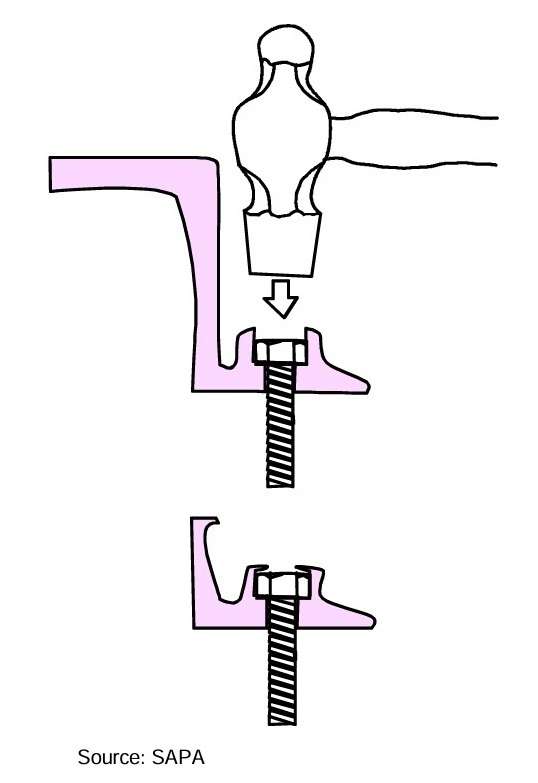

The elevation on the profile is placed so that the bolt if fixed in its position, which simplifies assembly (Figure 10).

Figure 10 – The elevation on the profile to fix the bolt in its position

Figure 10 – The elevation on the profile to fix the bolt in its position

Assembly is simplified if the screw is fastened to the part in manufacturing stage (Figure 11).

Figure 11 – The screw is fastened to the part in manufacturing stage

Figure 11 – The screw is fastened to the part in manufacturing stage

Snap Joints

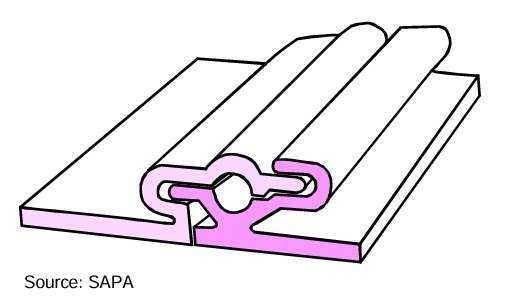

The elasticity of aluminium and absence of attachments make snap joints much faster than welded or bolted joints. The design of the joint is chosen with respect to the function of the product; e.g. if the joint is to be opened or not. In the upper example, it is possible to open the joint by use of a screwdriver. The other alternative gives a permanent connection. Figure 12 shows snap joints used in windows and side panels on trucks. The design of the joint is chosen with respect to the function of the product, e.g. if the joint is to be opened or not. In the upper example, it is possible to open the joint by use of a screwdriver. The other alternative gives a permanent connection.

Figure 13 illustrates another type of joint that may be opened and closed. The outer groove gives support for a screwdriver. Dimensions and tolerances must be determined from case to case. The length of the elastic cantilever should not be less than 15 mm. In some cases, the cantilever must be pressed with force thus eliminating the need of special tolerances.

Figure 13 – Another type of snap joint

If the connection is to be opened and closed often, the elastic profile should be replaced by another material such as plastic clip, with regards to fatigue.

Figure 14 – The snap connection with a plastic clip

Figure 14 – The snap connection with a plastic clip

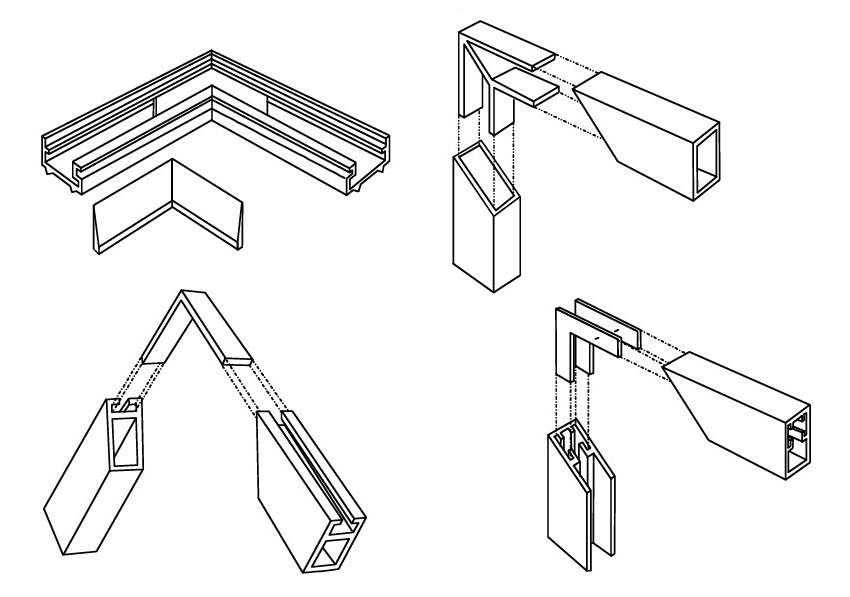

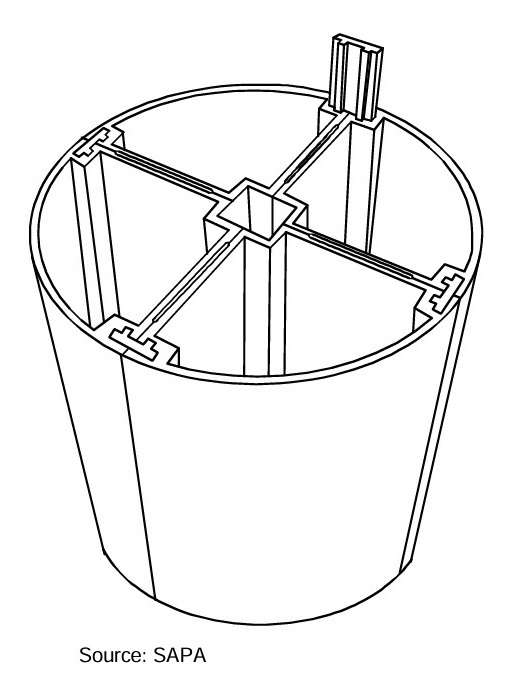

Corner bloks

Corner blocks are used in corner joints that demand strength and stiffness. The block itself, which can be cast, or as in most cases a profile cut into short lengths, is fastened by pressing or by screws into both profiles.

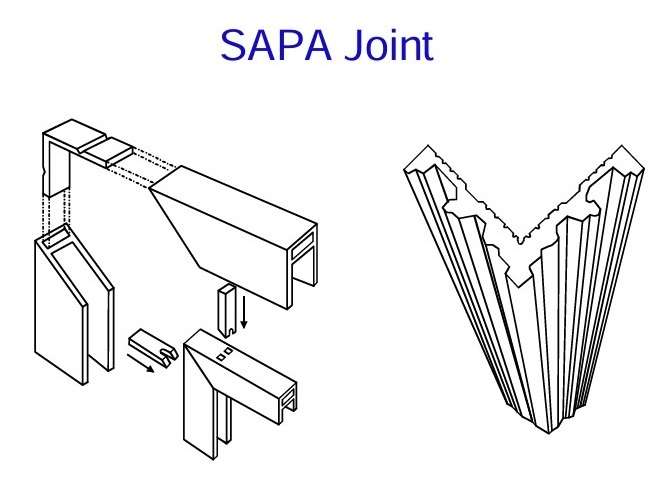

In frames and other light structures, the corner blocks consist of a pressed steel angle. The SAPA Joint is an example of a corner joint. The width of the joint profile can be cut to fit a hollow section regardless of its width.

Figure 16 – The corner blocks consist of a pressed steel angle

Figure 16 – The corner blocks consist of a pressed steel angle

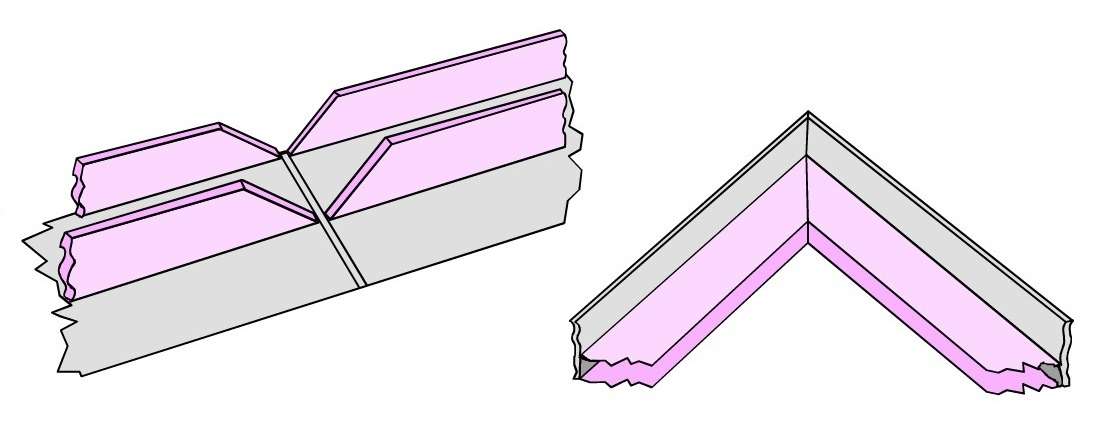

This figure shows Mitre Joints. Mitre Joints are a common method of producing corners in frames where the same profile is used in three or four sides. It is possible to bend the profile once. Repeated bending will cause the material to crack.

The source:

TALAT Lecture 2302 – Design of Joints / T. Höglund – 1994. Updated according to EC9 by Federico M. Mazzolani – European AluminiumAssociation – 1998.