Mechanical Joining of Thin-Walled Aluminium

Joining is an important and often critical process step in the manufacturing of aluminium components from shaped sheet and/or profiles.

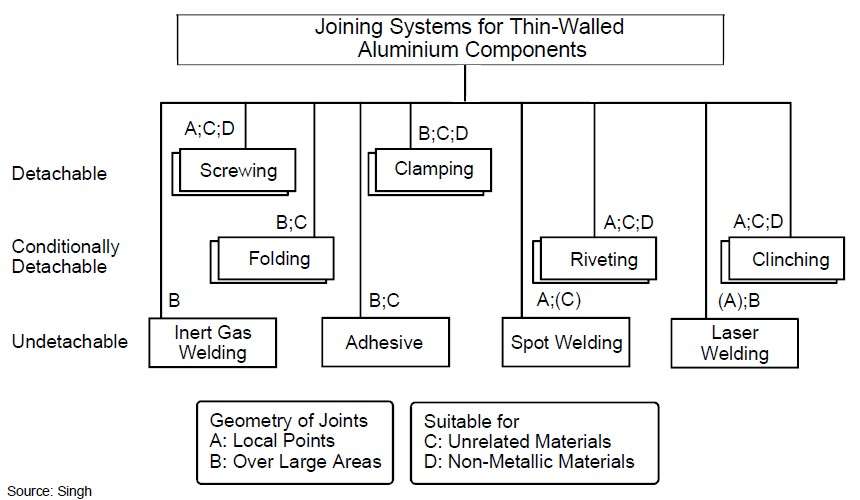

Depending on the task and conditions, various methods are used to join thin-walled aluminum to itself or to other materials, metallic and non-metallic. These connections can be detachable (screwing, clamping), conditionally detachable (folding, riveting, clinching) and undetachable (welding, adhesive). In addition, they can be designed to connect local points or over large areas, as well as joining different materials, unrelated and non-metallic.

Figure 1

Here we will consider main mechanical methods of joining thin-walled aluminium, such as: screwing, folding and riveting.

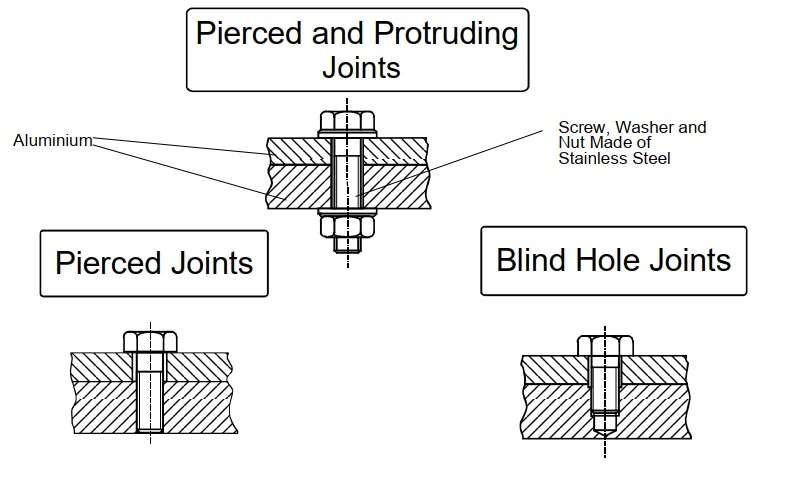

Screw joints belong to the group of detachable joints. These can be designed as pierced, through or blind-hole joints. If appropriate measures are taken against corrosion, screw joints are suitable for shaped sheet components and /or aluminium sections and profiles.

The joining elements are made of corrosion resistant stainless steel (steel group A2/A4). Since aluminium alloys have relatively lower compressive strengths, the contact surfaces must be protected by using washers under the screw and the nut.

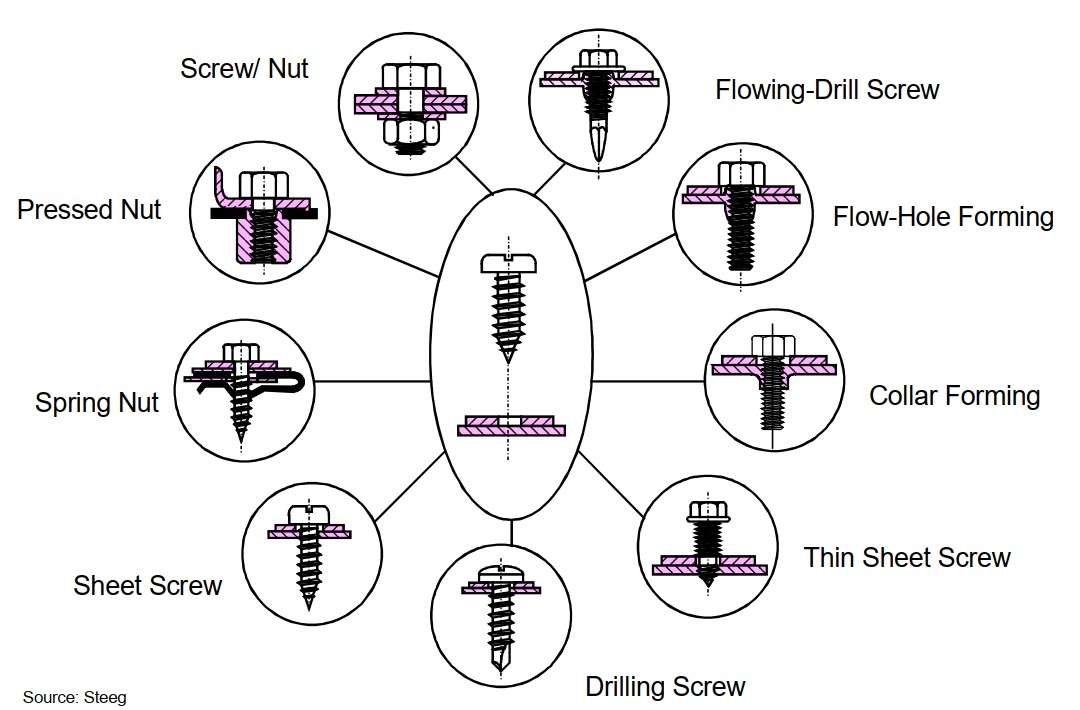

In addition to the screw-and-nut fastening methods, thin sheets can be joint together using a number of threaded fasteners, the most popular being sheet metal screws of the self-locking, self-tapping types.

With the help of screw-and-nut fasteners, it is possible to create large clamping forces. Sheet metal screws, on the other hand, are used to eliminate the drilling operation for the final assembly, whereby the screw cuts out its own hole.

A drawback of most sheet metal screw joint is the very limited load bearing length of the screw. Improvements can be made by forming cylindrical collars during the shaping process.

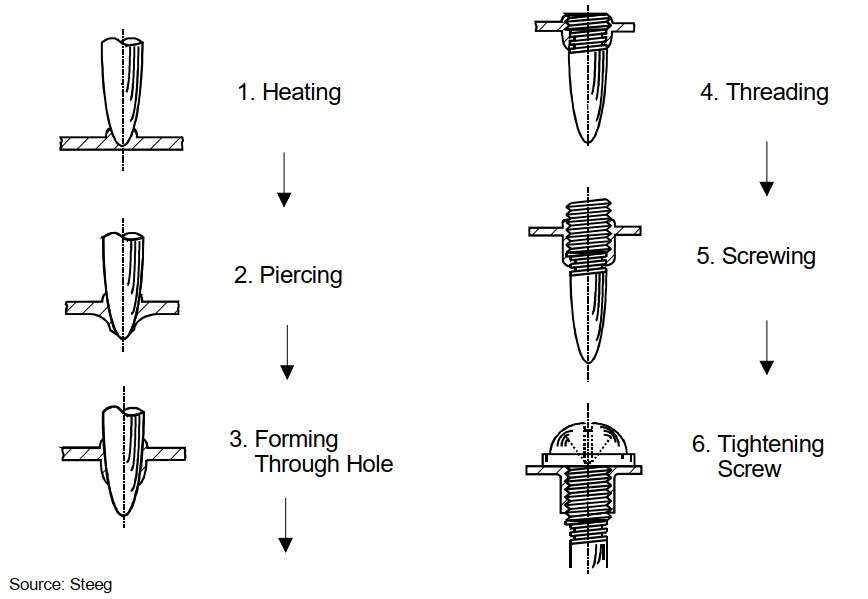

In the flow-drilling process, a carbide tipped tapered and unthreaded punch rotating at high speed is forced down to pierce through the metal, deforming it plastically and creating a collared hole. A thread can then be tapped in this hole.

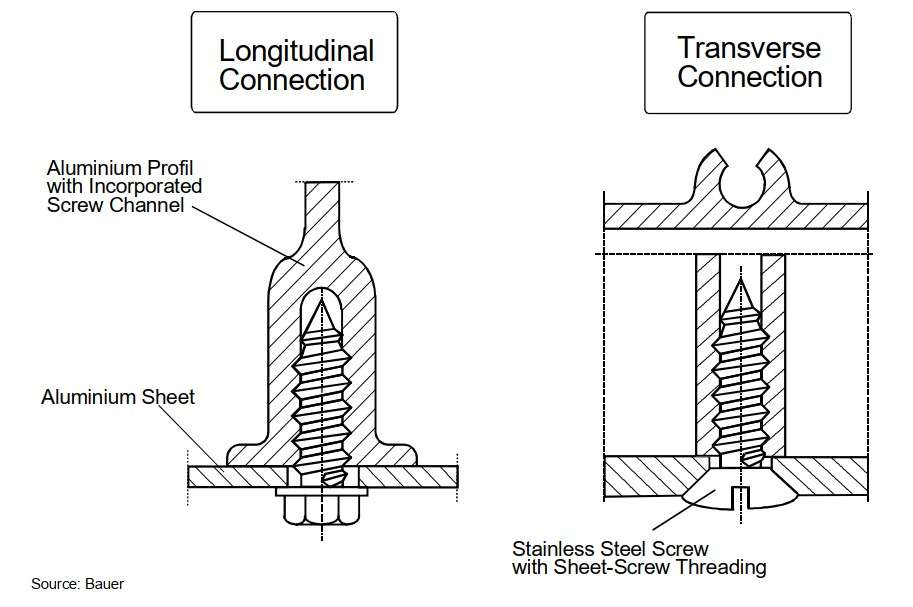

Stainless steel sheet metal screws are most often used for joining light metal alloys. Prefabricated profiles are being increasingly used for aluminium constructions. The profiles have longitudinal and transverse screw channels (or grooves) to take up the stainless steel screws.

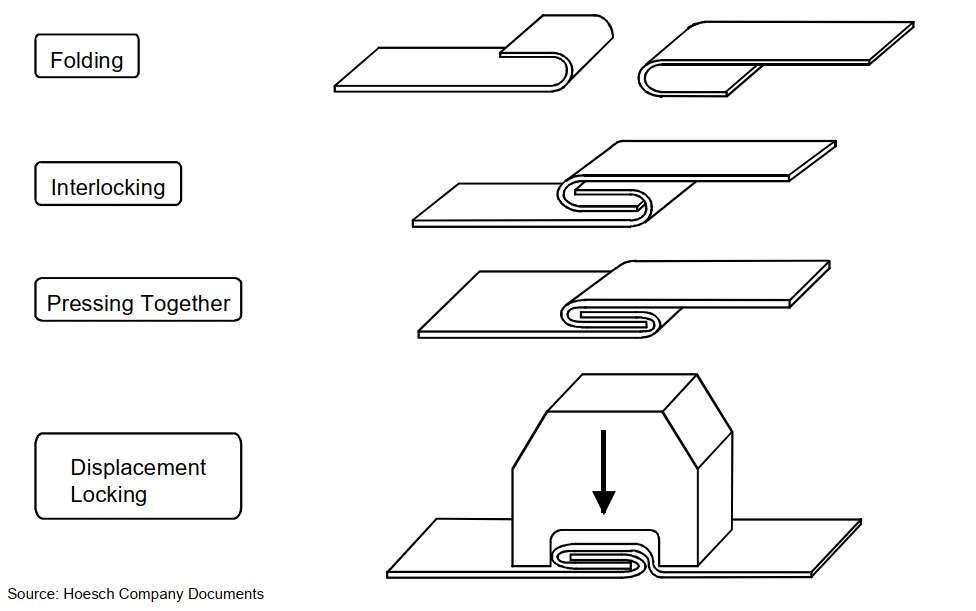

Folding techniques are traditionally used for joining aluminium effectively. Form locked joints are created using the following steps: folding, interlocking, pressing together and locking by displacing the sheet edges. If this fastening method is carried out properly, the protective oxide film is not damaged so that the surface remains protected.

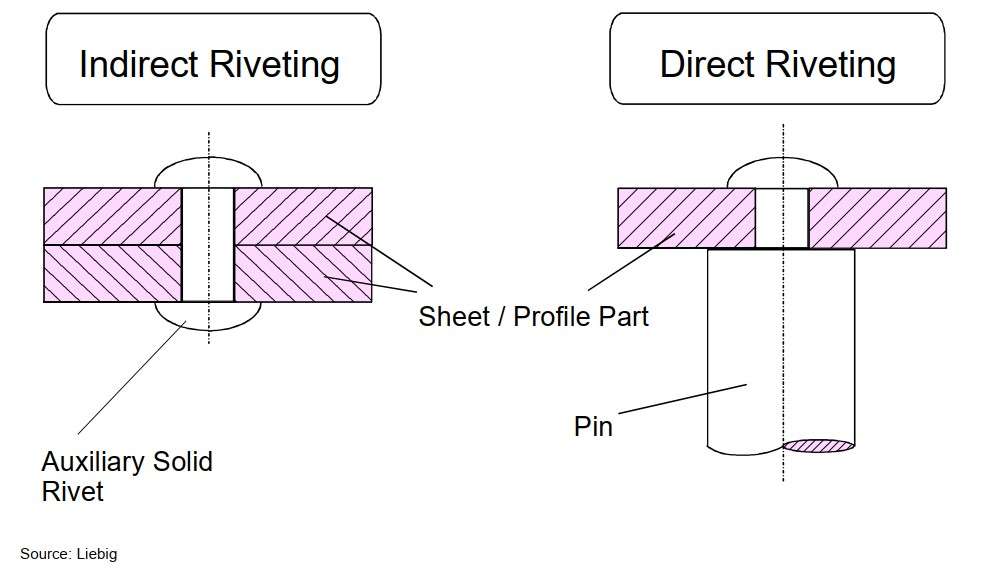

Riveting is being rediscovered as a rational technology of high quality especially for special-purpose applications in the aerospace industry. Aluminium can be joined using the indirect and direct riveting methods.

In the indirect riveting process the parts to be joined are clamped together with rivets using an auxiliary joining element. In direct riveting, one of the parts to be joint is itself designed to act as the auxiliary component so that a separate one is not necessary.

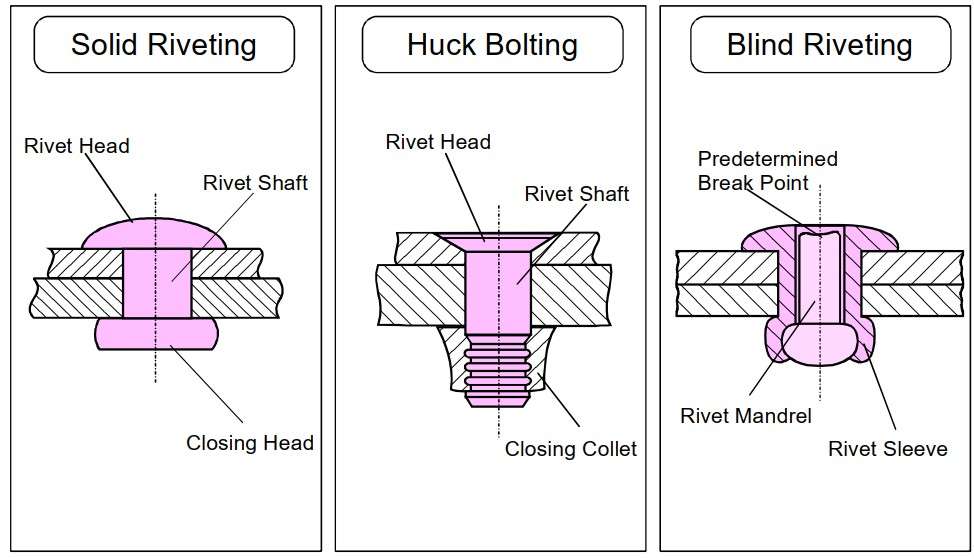

Three main types of indirect rivets are used for producing undetachable (permanent) joints: solid rivets, blind (pop) rivets and huck bolts (screw rivets). There are other, more complex, types of indirect rivets, such as punch rivets.

Solid rivets are one-piece joining elements in which the rivet shaft is plastically formed into the closing head. Such rivets can only be used for components which are accessible from both sides.

Huck bolts (screw rivets) are used for highly stressed rivet joints. Since screw rivets are made of high strength materials which cannot be formed easily during assembly, a closing collet (self-locking nut) is fixed on to the rivet.

Blind (Chobert, pop) rivets, including the multi-functional types, consist of one or more elements and require only one accessible side for mounting. Punch rivets are designed to be self-piercing, making it unnecessary to form holes previously in the parts to be fastened.

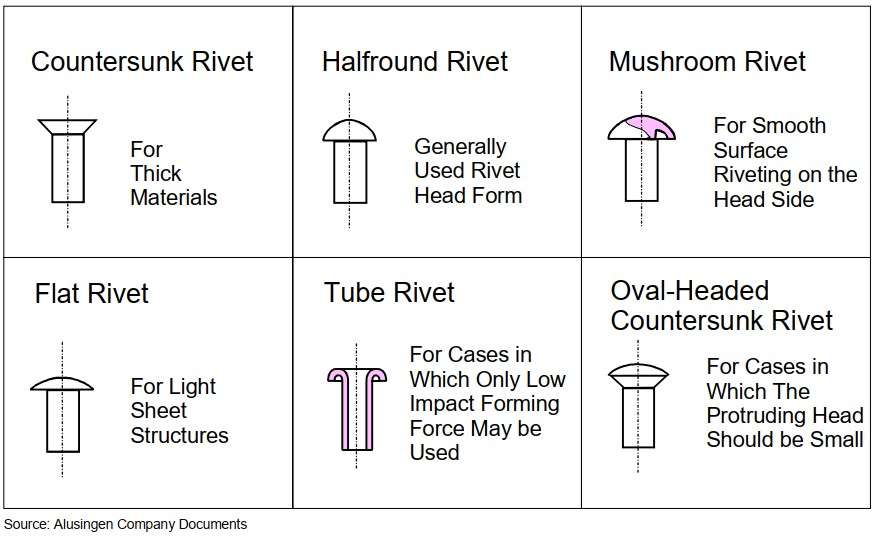

Rivets are classified according to the shape of the rivet head formed during the riveting. For sheet metal and light constructions which do not need rivets of greater than 8 mm diameter, closing heads with the same form as the rivet heads can be used. Aluminium rivets having a diameter of up to 8 mm can be fairly easily cold worked.

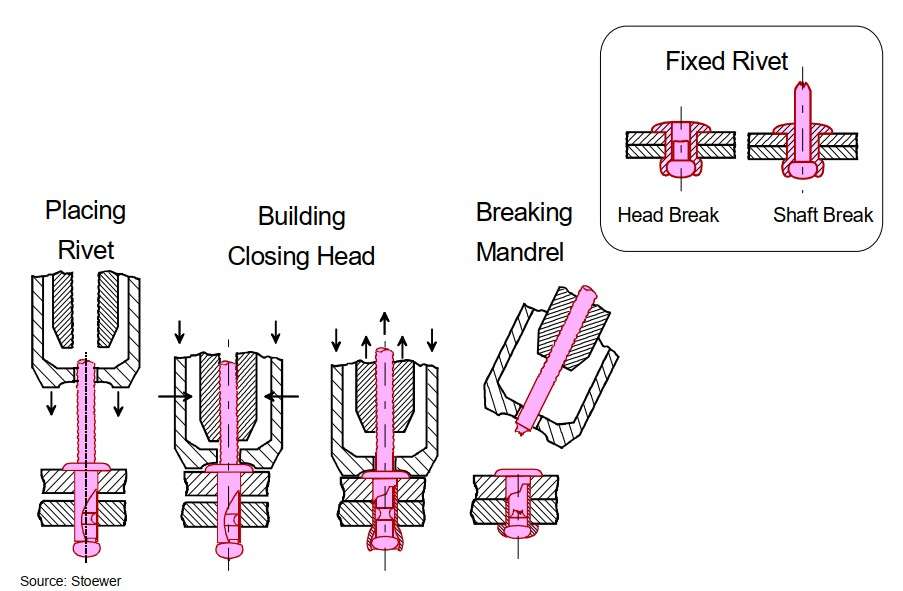

Just like many other innovative rivet developments, the blind rivet was developed in the aircraft industry. Generally, blind rivets consist of a hollow shaft and a pull-stem (mandrel) which serves as a tool for forming the closing head.

The rivet is mounted by pulling the stem out with a special tool, whereby the stem head is drawn into the protruding rivet material to form the closing head. When the pulling force exceeds a certain level, the stem breaks at a predetermined position (notched or break-stem). The breaking point can be chosen to lie either in the shaft or at the rivet head.

Mechanical fasteners using auxiliary fastening elements should be chosen so that both fastener and the components to be joint are compatible as far as corrosion and recycling aspects are concerned. It follows that the parts which come in contact with each other must have similar electrochemical potentials and the material combination used must be tolerant with respect to recycling.

Fastening elements made of copper or brass are not suitable for joining aluminium parts. In an environment where the joints are subjected to weathering or chemical attack, the parts must be isolated from the fastening elements, both for aluminium parts of different alloys as well as for composite constructions.

The source:

TALAT Lecture 4101 – Definition and Classification of Mechanical Fastening Methods / Lothar Budde – European Aluminium Association – 1994