Aluminium machinability

Understanding machinability of aluminium alloys, from low strength wrought alloys to heat hardened thermally non-hardened alloys. Machinabilty of Aluminium alloys includes AlMn, AlMg1, AlMg2, AlMg3, AlMg4, AlMg5, AlMgMn and AlMg4,5Mn.

Aluminium machinability: European classification

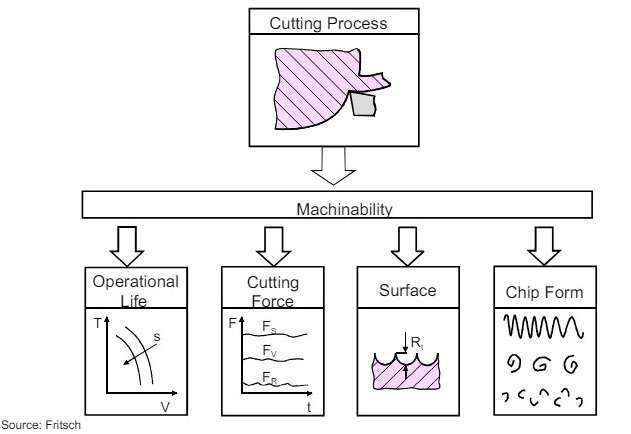

Figure 1 – Definition of machinability [1]

Figure 1 – Definition of machinability [1]

The groups of aluminium machinability

From the point of view of machinability, aluminum alloys are divided into the following groups (in order of increasing difficulty of machining):

- Group 1: Low strength wrought aluminium alloys;

- Group 2.1: Deformable aluminium alloys of increased strength;

- Group 2.2: Aluminium alloys for machining;

- Group 3.1: Aluminium-silicon alloys with silicon content up to 10 %;

- Group 3.2: Eutectic aluminium-silicon alloys;

- Group 3.3: Hypereutectic aluminium-silicon alloys.

Group 1: Low-strength wrought aluminium alloys

1) Thermally non-hardenable alloys in annealed state or partially cold-worked state:

Examples of alloys:

- AlMn,

- AlMg1,

- AlMgMn.

2) Heat-hardening alloys in unaged state:

Examples of alloys:

- AlMgSi0,5,

- AlMgSi1.

Characteristic properties for machining:

- soft,

- plastic,

- low strength,

- no solids,

- tendency to stick to the cutting edge.

Group 2.1: High strength wrought alloys

1) Heat-hardened thermally unhardened alloys:

Examples of alloys:

- AlMn

- AlMg1, AlMg2, AlMg3, AlMg4, AlMg5

- AlMgMn

- AlMg4,5Mn

2) Heat treated alloys in aged and / or cold-worked condition:

Examples of alloys:

- AlCuMg1

- AlZnMg1

- AlZnMgCu0,5

- AlZnMgCu1,5

Characteristic properties for machining:

- strength from 300 to 600 N / mm2 with good elongation,

- no solids – low tool wear,

- decrease in strength with increasing tendency to stick to the cutting edge.

Group 2.2: Aluminium alloys for machining

Thermally treated wrought alloys with additives for chipbreaking

Examples of alloys:

- AlMgSiPb

- AlCuBiPb

- AlCuMgPb

Characteristic properties for machining:

- short chips due to the presence of Pb and Bi additives;

- strength from 280 to 380 H / mm2;

- low tendency to stick on the cutting edge.

Group 3.1: Al-Si cast alloys with silicon content up to 10 %

1) AlSiCu alloys

Examples of alloys:

- AlSi5Cu1

- AlSi6Cu4

- AlSi8Cu3

2) AlSiMg alloys

Examples of alloys:

- AlSi7Mg

- AlSi9Mg

- AlSi10Mg

Characteristic properties for machining:

- strength from 250 to 360 N / mm2;

- increased wear of the cutting tool due to hard components of the microstructure and inclusions;

- good chip brittleness and smooth surface;

- the tendency to stick to the cutting edge with the content aremniya more 5 %.

Group 3.2: Low hardness Al-Si cast alloys

Al-Si alloys with a silicon content of about 12 %

Alloy example:

- AlSi12

Characteristic properties for machining:

- low hardness of the aluminium matrix;

- solid metal microstructure components and inclusions;

- high propensity to stick on the cutting edge.

Group 3.3: High hardness Al-Si cast alloys

Al-Si alloys with silicon contents exceeding 12 %

Examples of alloys:

- AlSi18CuMgNi

- AlSi21CuNiMg

- AlSi25CuMgNi

- AlSi17Cu4FeMg

Characteristic properties for machining:

- medium strength;

- high hardness;

- very low plasticity;

- high wear of the cutting tool due to very hard intermetallic particles and primary silicon;

- high propensity to stick on the cutting edge.

Sources:

- Machining of Products – TALAT Lecture 3100 /P. Johne, Aluminium-Zentrale e.V., Düsseldorf – 1994

- Aluminum and Aluminum Allooys – ASM Speciality Handbook – Ed. J.R. Davis – 1993