How to work with adhesives on aluminium

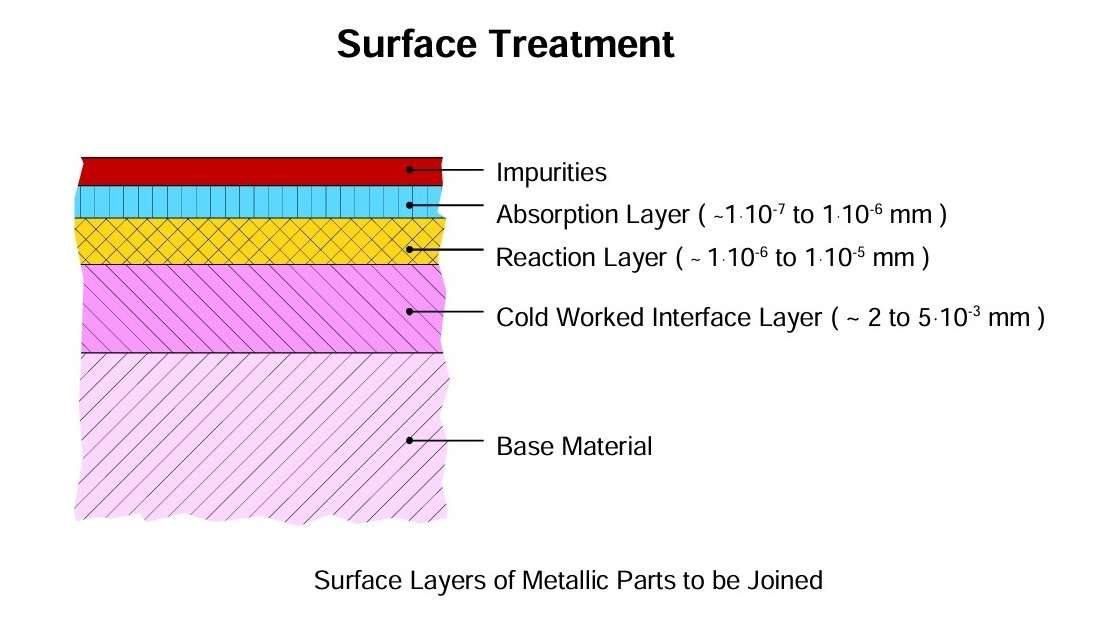

The surfaces of parts which have to be joint are treated prior to joining in order to have an optimal adhesion force between joint part surface and the adhesive layer. For this purpose it is absolutely necessary to first remove impurities in an undefined layer thickness (i.e., dust, dirt, oil, grease, fat, water) and the inactive adsorption layer created by foreign molecules (i.e., water, gases).

The whole surface treatment can be subdivided into a preparation, pretreatment and after-treatment operation. In general, an active surface for adhesives can be created by cleaning and increasing the surface area, creation of lattice defects on the surface and changing the chemical structure of the surface. In cases where a longer time-lapse is expected between the surface treatment and the adhesive joining, the surface of the joining parts should be conserved, using for example, a primer.

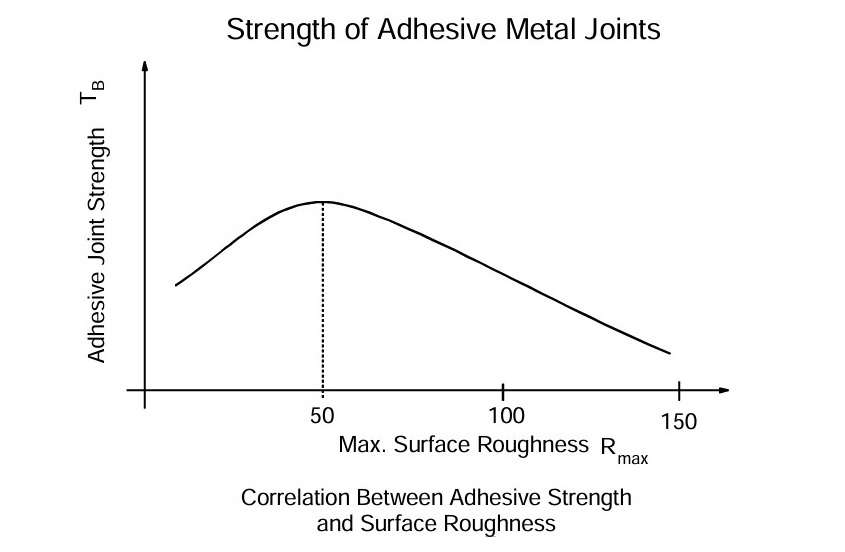

In view of the attainable strength of the adhesive joint and the notch sensitivity of most aluminium materials, the mechanical surface pretreatment should deliver only a low maximum roughness.

The possible application processes, depending on the consistency (solid or fluid) of the adhesive and on the application method used (manual or mechanised), have been listed in Figure 4.

A large variety of equipment is available for working with the adhesives. The working principle of a 2-component dosing and application machine is illustrated in Figure 5.

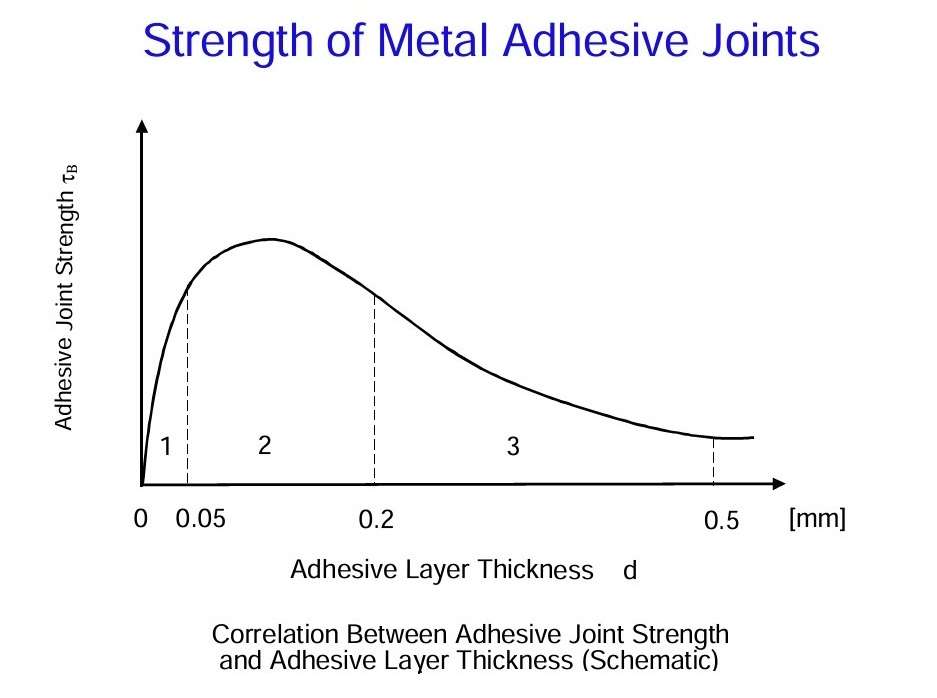

Generally, an adhesive layer thickness of about 50 to 200 µm should be strived at. It should be remembered that the adhesive layer thickness depends, to a large extent, on the pressure applied during setting or curing.

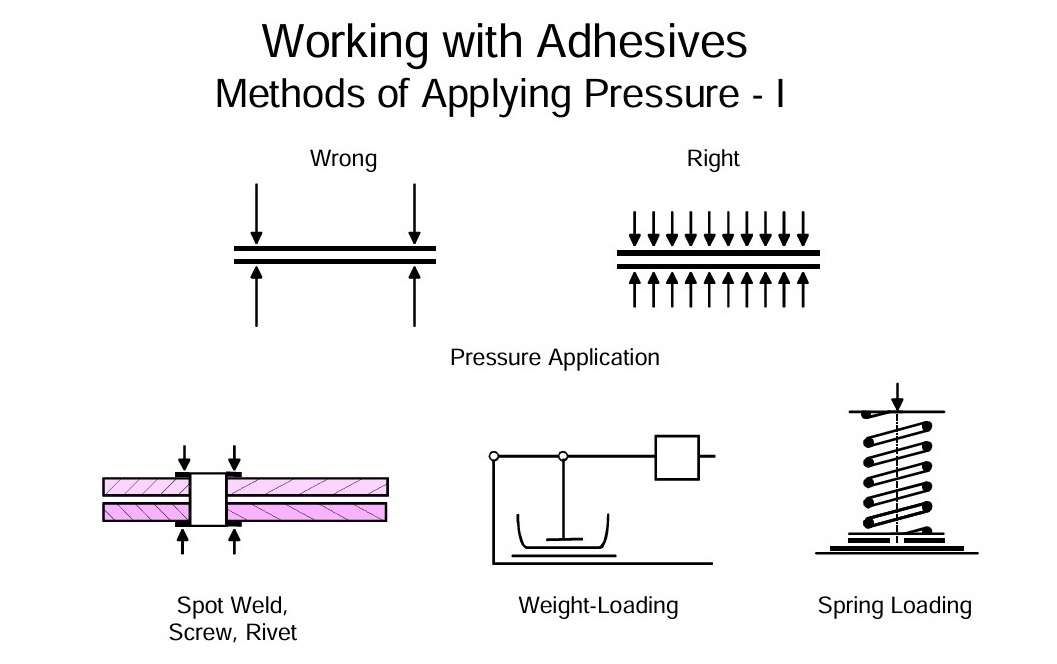

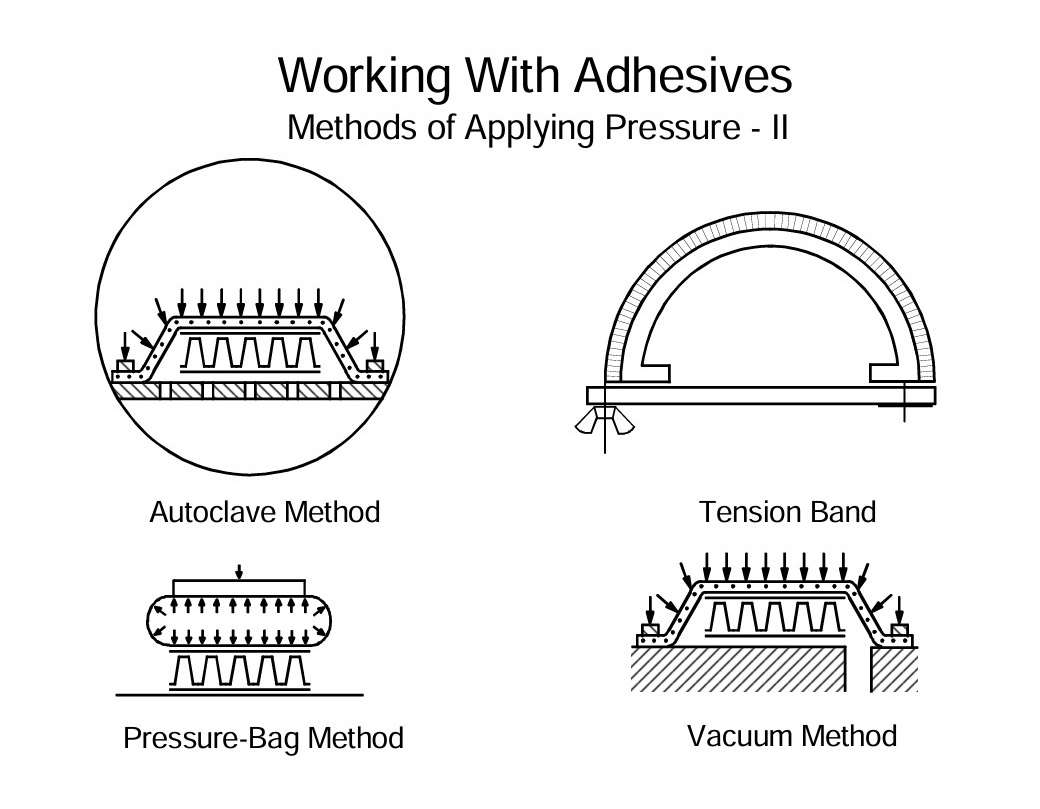

The possibilities of applying pressure during the hardening of the adhesive are shown in the two following figures.

Most adhesives require only a contact pressure (about 0.1 N/mm2). Adhesives, which react chemically and produce by-products during the curing process are an exception.

The method of applying pressure from all sides, like in the autoclave method, should be used preferably.

Usually, a functional correlation exists between hardening time and hardening temperature. Especially in the case of cold-hardening adhesives, the strength can be increased by hardening at higher temperatures or by tempering (after the cold-hardening). It should be noted that the temperature, pressure and time recommendations of the manufacturer apply for the adhesive layer. Heating times for the joining parts and for the adhesive equipment must be determined and considered.

The quality assurance in adhesive joining starts with the choice of suitable adhesives and continues with the control and regulation of the adhesive, auxiliary mediums, joining parts, adhesive preparation and working and the adhesive joining. The biggest problem is that a completely non-destructive method for testing adhesive joints does not exist. Consequently, preventive measures are most important: quality should be produced and not tested. The test methods are based on the tests for metals which have been correspondingly modified. The statistical destructive methods serve primarily to determine and control characteristic values for the adhesive.

A disadvantage of all non-destructive tests is that these allow the measurement of pores, non-uniform adhesive layer thickness and absolute joining defects but not, however, the quality of adhesion of the adhesive and joining parts surfaces. Specially prepared test samples which are also run through the normal manufacturing process are used to control the adhesive joining process. The simplest form of test sample is the peel sample.

The source:

TALAT Lecture 4704 – Surface Preparation and Application Procedures / Lutz Dorn – European Aluminium Association – 1994