Designing an Aluminium Profile

Discover the possibilities of designing aluminium profiles with insights from industry experts. Learn how to construct cost-effective and optimal profiles for various industries.

AEC Webinars: From Pro to Pro

A source of valuable information are the webinars of the American Aluminum Extruders Council – The Aluminum Extruders Council. The purpose of these webinars is to reveal to engineers, constructors, designers, as well as managers and marketers huge possibilities of extruded aluminium profiles in construction and design, in the automotive industry, in household and sports goods.

Experienced professionals in their field – technologists and material scientists, designers and production managers share their secrets:

- How to construct a profile, so that its production is as cheap and optimal as possible?

- What is “good” and what is “bad” in designing aluminium profile?

- What elements need to be laid in an aluminum profile, so that it can perform its functions as optimally as possible?

- What benefits can be obtained, if you replace parts made of traditional materials, for example, steel, on parts made of aluminum alloys?

Design of extruded aluminium surface quality

Aluminium philosophy

Aluminum as a material and aluminum extrusion as a process offer unique properties and technological capabilities to product designers for various markets. A deep understanding of the unique capabilities of aluminum alloys and the extrusion process – the philosophy of aluminum – opens up boundless spaces for the designer for creativity and creation of new solutions for all areas of human activity.

- How to use the unique properties of aluminum to develop new products?

- What can different aluminum alloys and their variants give to the designer?

- What are the benefits of using more complex profile designs?

- What effective technologies are used when working with aluminum?

Possibilities of structural aluminium

These and other issues were discussed at the last webinar from 4 November 2016 of the year, which was organized by one of the leaders in the aluminum industry, SAPA corporation.

Webinar topic: Leveraging Aluminum’s Attributes for Effective Extruded Solutions

This one-hour webinar provides a visual and detailed overview of the many nuances of aluminum profile manufacturing., a, the main thing, emphasizes all the advantages of aluminum as a material and extrusion as a technology to achieve the most effective results when developing new aluminum profiles.

Focus of the report – three main levers for finding new solutions:

- selection of aluminum alloy,

- product geometry and

- production technology.

The choices in these three areas have been illustrated with numerous case studies across different areas and market niches..

After this webinar, you begin to better understand:

- possible solutions for the use of extruded profiles in a wide variety of products;

- possibilities and limitations of various aluminum alloys;

- techniques for designing effective aluminum profiles with minimal costs for their production.

Below we present some excerpts from this webinar, which were especially helpful to us. You may like other.

In addition to acquiring technical knowledge, there is also another benefit – natural spoken English on familiar technical topics. English is never superfluous for a true professional!

Below we present the first part of the review of this webinar.

Aluminium extrusion

When extruding aluminium, the essence of the process remains the same – to push the soft material through the specified holes (Figure 1).

Figure 1- Aluminum extrusion

However, in fact, aluminum extrusion is a difficult and multifactorial process. To obtain aluminum profiles of a given shape with a good surface and high strength, complex equipment is used., which includes not only a powerful and high-precision extrusion press, but also several ovens, drank, roller tables and conveyors (figure 3).

Figure 2 – Extrusion line for aluminum profiles

In the aeging oven (Figure 4) profiles from heat treatable aluminium alloys, for example, 6060 и 6063, reach the specified temper of the material. A temper specifies mechanical and other properties of the aluminium alloy. These tempers are indicated by letters and numbers., for example, T5, T6, T66.

Three important technological steps

When the specified mechanical properties of the aluminum profile are achieved, the following three technological operations have a very important effect:

- №1 – The temperature of the metal when passing through the matrix must have a temperature, which is sufficient for the complete dissolution of all alloying elements in aluminum

- №2 – After the profile leaves the matrix, it should receive sufficiently intensive cooling., to keep Mg2Si particles in a solid solution of aluminum and, in the same time, avoid excessive warping of the profile (figure 5)

- №3 – The profile to undergo a complete artificial aging for the growth and release of hardening precipitates based on Mg2Si.

Aluminium for innovations:

- light weight

- strength

- high strength / weight ratio

- elasticity

- corrosion resistance

- electrical conductivity

- non-magnetic

- does not spark

- incombustible

- durable in the cold

- complete recycling after service life

Extrusion benefits:

- metal there, where is it needed

- complex thin-walled shapes

- attractive view, color spectrum

- lack of seams

- minimum porosity

- ease of processing

- many ways for connections

- precise assembly of many elements

- uniform quality of the entire batch of products

- favorable for the price

- quick launch into production

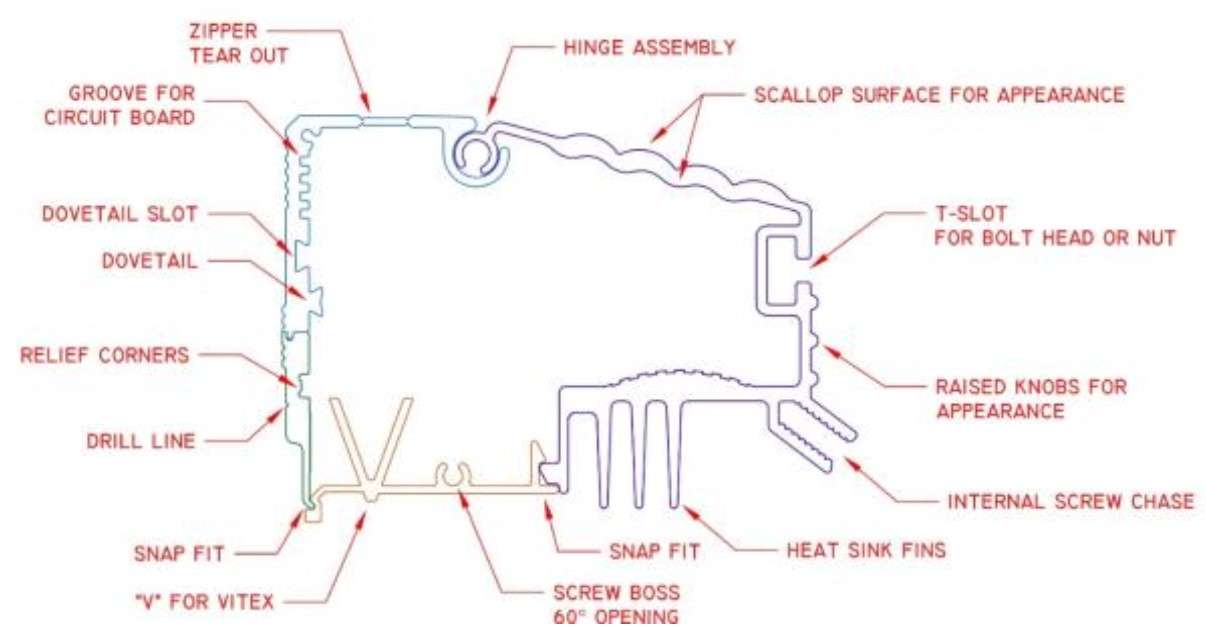

Functions of aluminium profiles

Figure 3 – Functional elements of aluminum profiles

Figure 3 – Functional elements of aluminum profiles

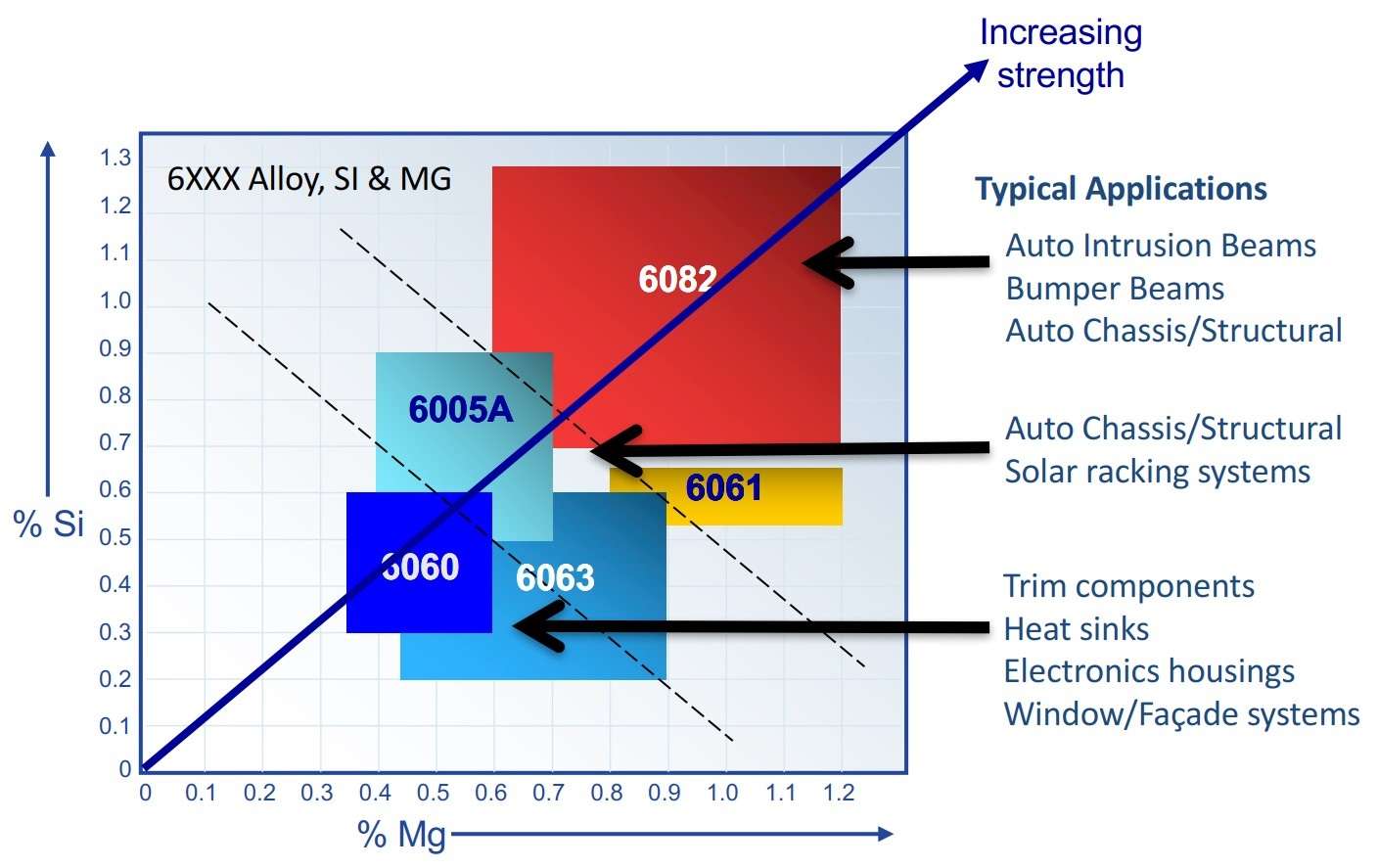

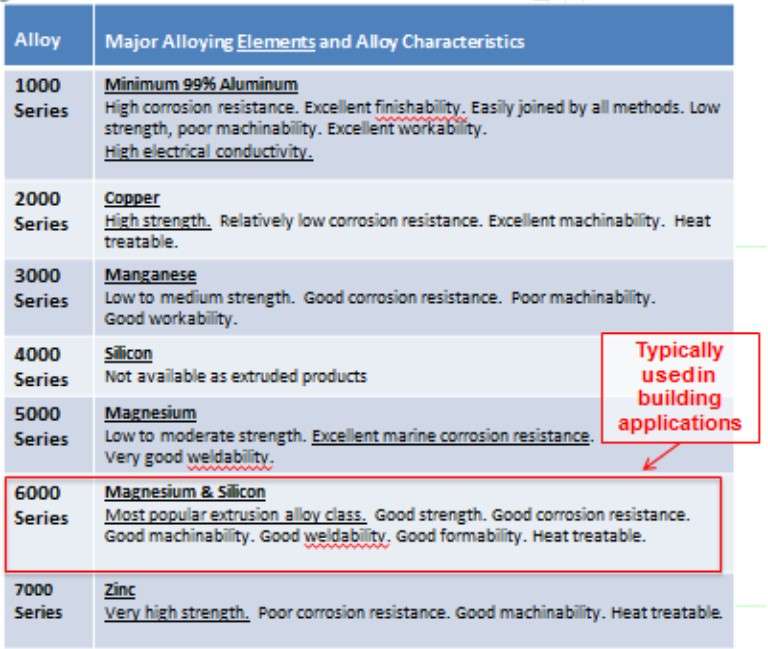

Alloy Selection

Extrusions are available in a variety of alloys and tempers. While other alloys may provide greater strength, electrical conductivity or other functionality, for most building and construction applications, 6000‐series alloys are ideal [2].

Figure 4 – The aluminium alloys for innovative projects [2]

Figure 4 – The aluminium alloys for innovative projects [2]

6xxx series alloys

6063, 6060:

- Lowest strength

- Slightly lower costs

- Good extrudability

- Good surface finish

6061:

- High strength

- Higher cost

- Lower extrudability

- Poorer surface finish.

6005A:

- High strength

- Moderate cost

- Good extrudability

- Good surface finish

- Recommended for structural applications

Resurces:

- https://aec.org/key-design-considerations

- https://aec.org/sites/default/files/2022-11/bcwhitepaper_rev01252019.pdf

- Aluminum Extrusion Dies: 7 Decisions that Increase Your Die Tooling Cost – AEC Webinar – May 8, 2019