How Aluminum Alloy Type Affects Machining Tool Wear

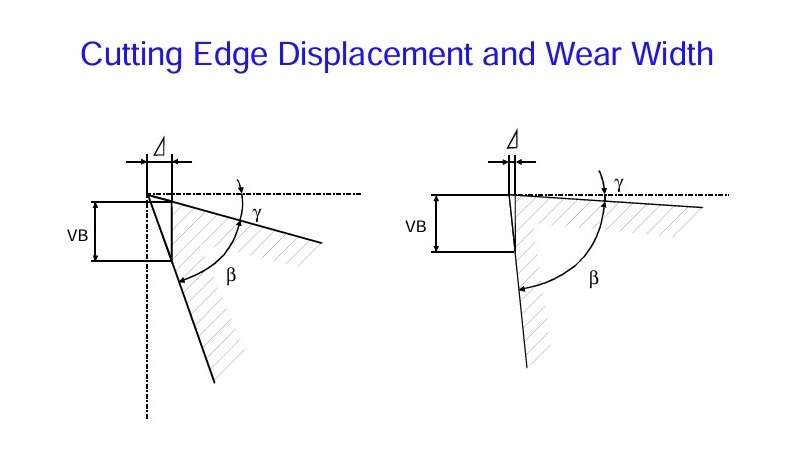

The tool wear while machining aluminium occurs due to abrasion of the free surface. Consequently, the deciding criterion for measuring tool life objectively is the wear width VB (Figure 1). The wear of the free surface depends on the temperature and is caused mainly by abrasion. While using carbide-tipped tools one normally assumes an allowable maximum value of 0 point 3 to 0 point 5 mm for VB.

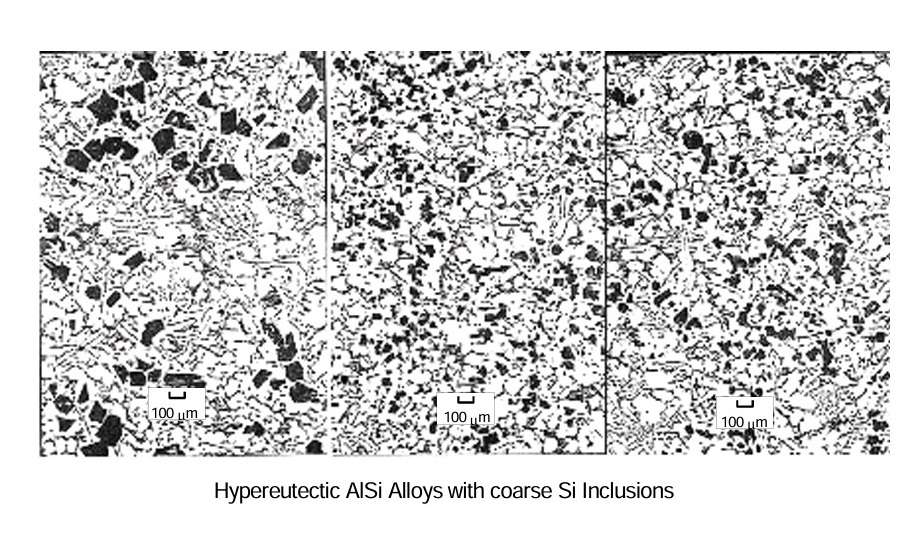

Wear increases with the number of large hard particles which are embedded in the aluminium workpiece. Such particles could be primary precipitations of silicon particles in a hypereutectic alloy Figure 2). This is the reason that aluminium castings cause high wear of tools.

Video: Which aluminium alloys are the most difficult to machine?

Hard particles in a soft matrix can be gouged out easily. If the matrix material is harder, inclusions cannot be removed easily, thus increasing tool wear.

Wrought alloys with low silicon contents cause a minimum of tool wear.

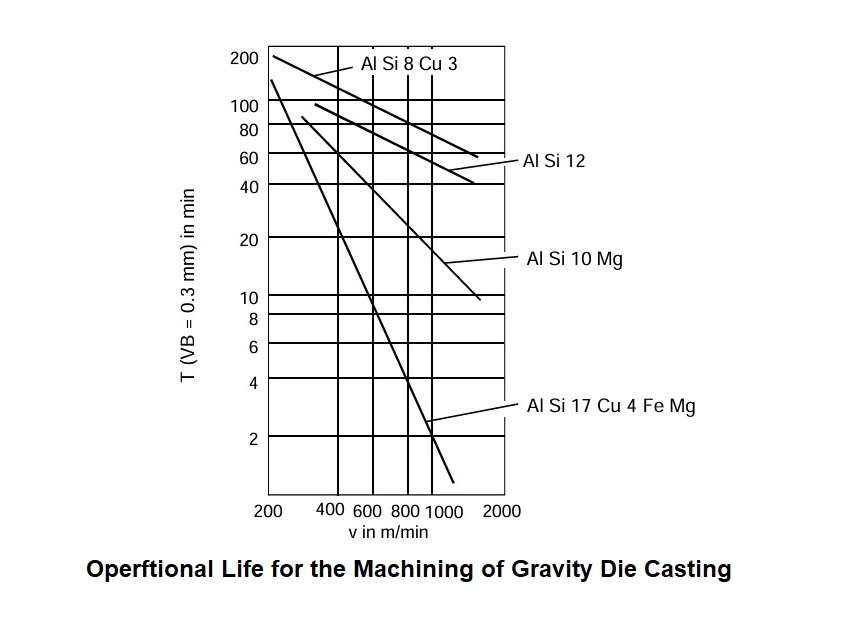

As far as cutting conditions are concerned, cutting speed has the greatest influence on tool life. The diagram shown in Figure 3 is an example for gravity die casting alloys. In the case of wrought alloys, the tool life is measured in number of shifts or days rather than in minutes.

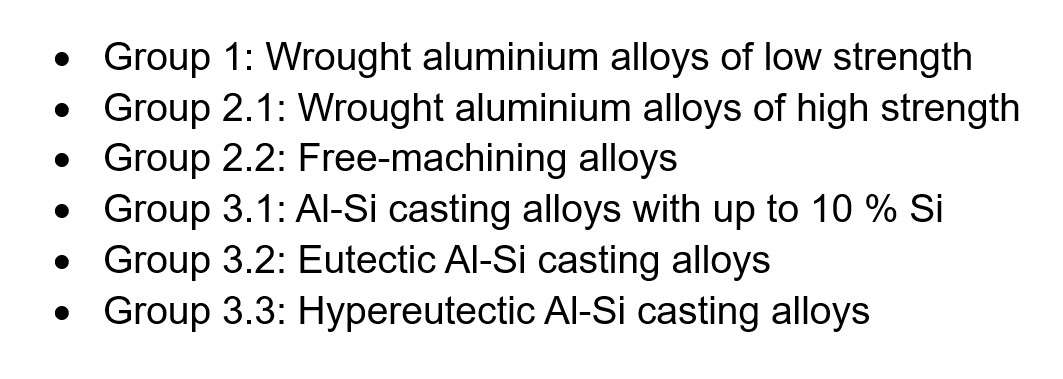

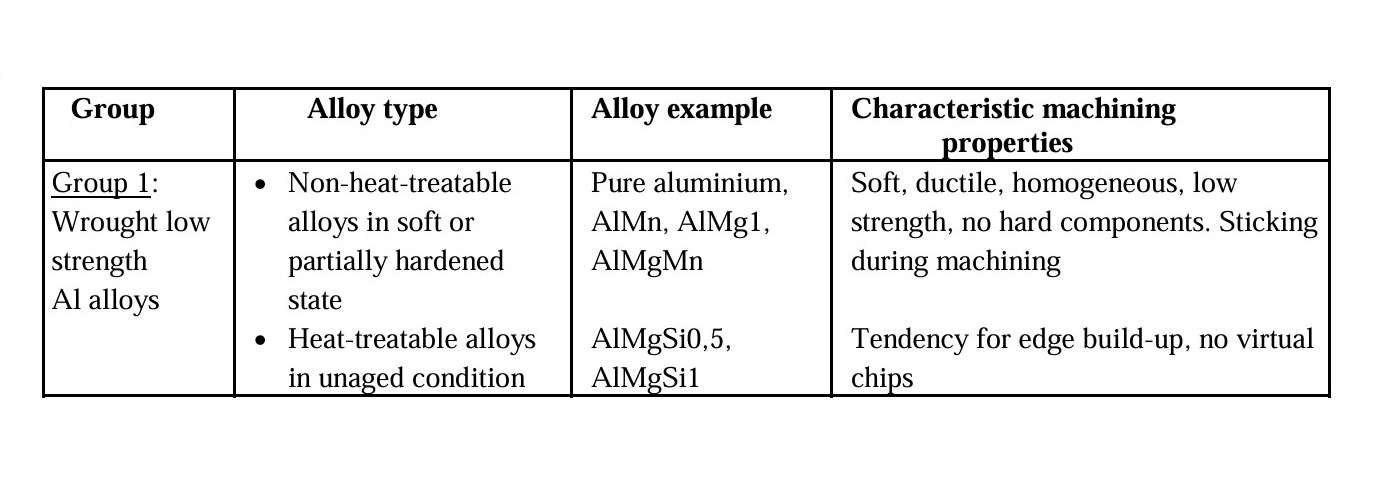

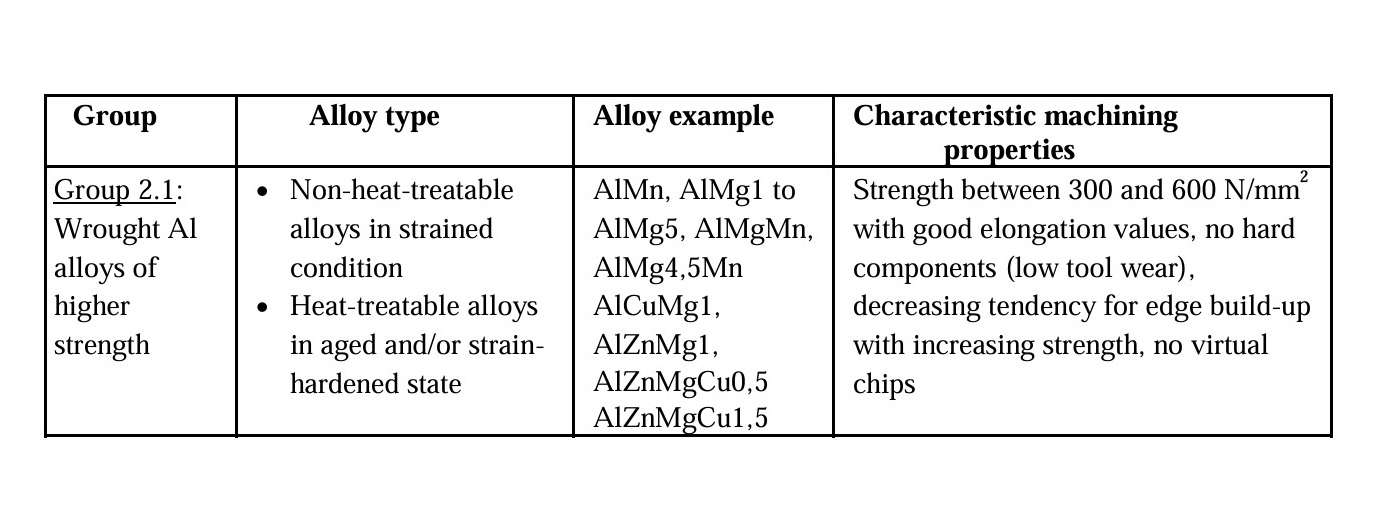

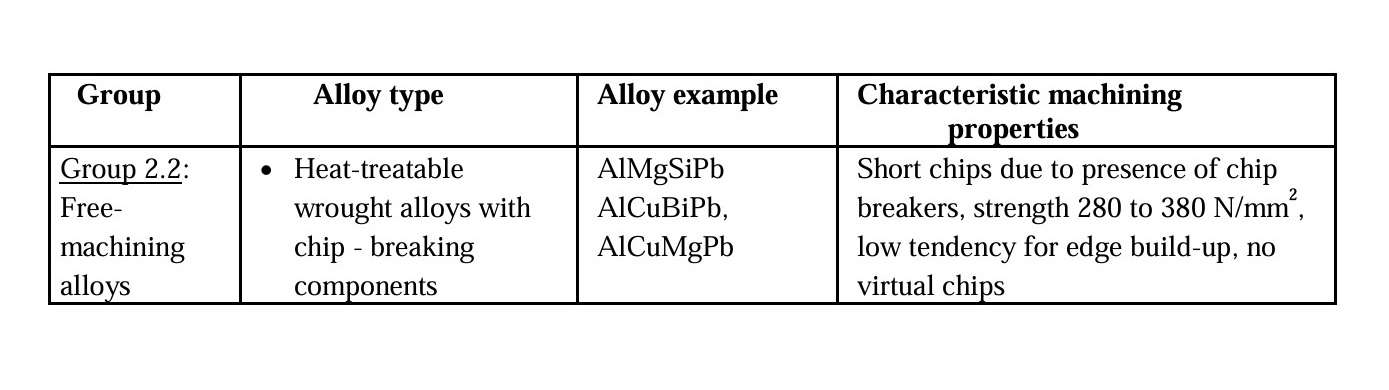

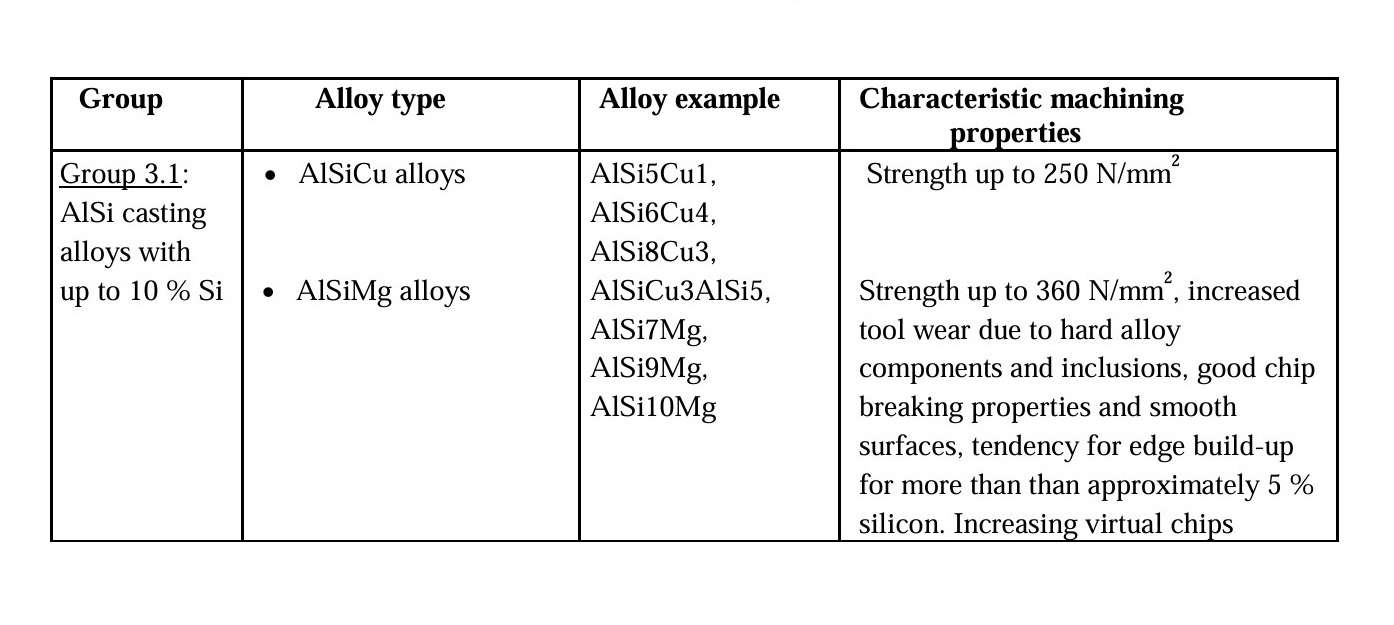

It could be classify aluminium alloys in groups having similar machining characteristics as it shown in Figure 4.

Group 1: Wrought aluminium alloys of low strength

Two alloy types:

- Non-heat-treatable alloys in soft or partially hardened state

- And heat-treatable alloys in unaged condition.

Group 2.1: Wrought aluminium alloys of higher strength

Two alloy types:

- Non-heat-treatable alloys in strained condition

- And heat-treatable alloys in ageid or strain-hardened state

Group 2.2: Free-machining alloys

One alloy type:

- Heat-treatable wrought alloys with chip-breaking components.

Group 3.1: Al-Si casting alloys with up to 10% Si

Two alloy types:

- Aluminium-silicon-copper alloys

- Aluminium-silicon-magnesium alloys

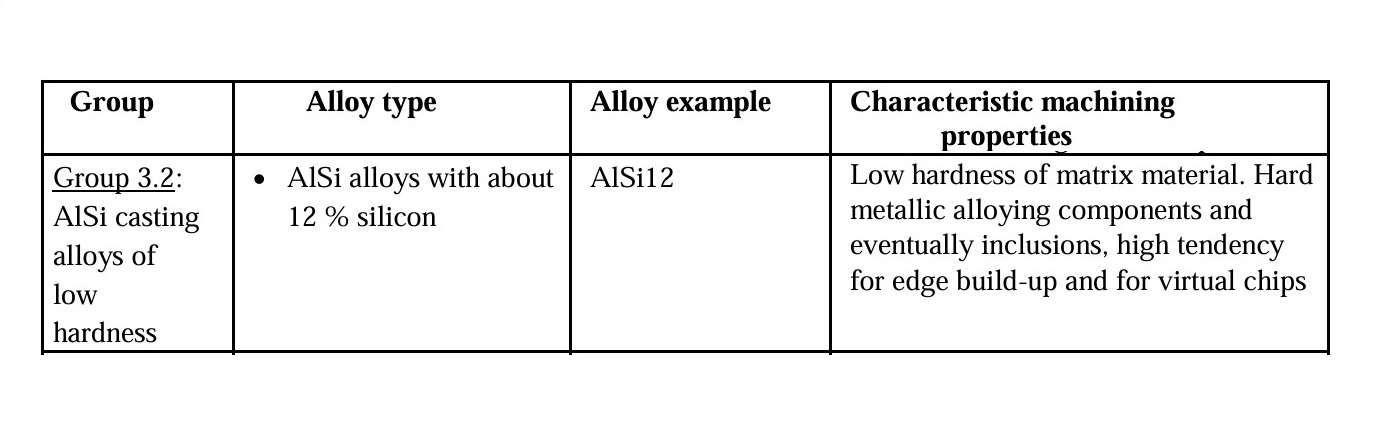

Group 3.2: Al-Si casting alloys of low hardness

One alloy type:

- Al-Si alloys with about 12 percent silicon.

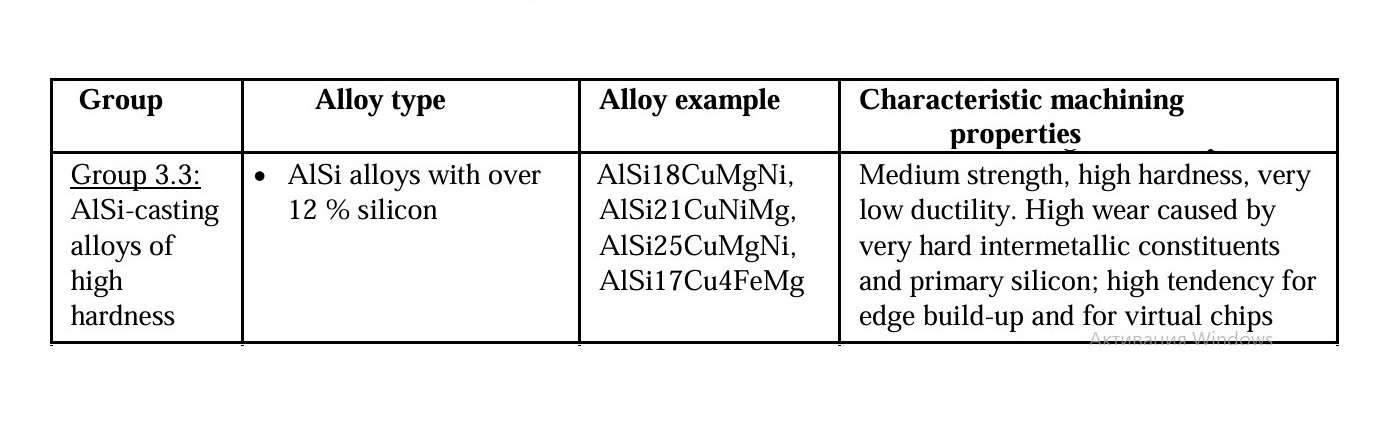

Group 3.3: Al-Si casting alloys of high hardness

One alloy type:

- Al-Si alloys with over 12 percent silicon

The source:

1. TALAT Lecture 3100 – Machining of Products / P. Johne – European Alumnium Association – 1994