A Brief History of Aluminium Car Wheels

The three basic elements of a car wheel

The three basic elements of a car wheel are the hub, the spokes and the rim. Sometimes these components will be one piece, sometimes two or three. The hub is the centre portion of the wheel and is the part where the wheel is attached to the suspension through the wheel carrier. The spokes radiate out from the hub and attach to the rim. The rim is the outer part of the wheel that holds the tyre.

Almost all modern aluminium wheels are made by one of two processes: casting and forging. Whereas styling has been the main motivation for cast solutions, forged wheels are usually lighter and stronger, but also more expensive than cast wheels. Nevertheless, with proper attention to material quality and process control, cast aluminium wheels can provide many years of good service.

Car wheel designing

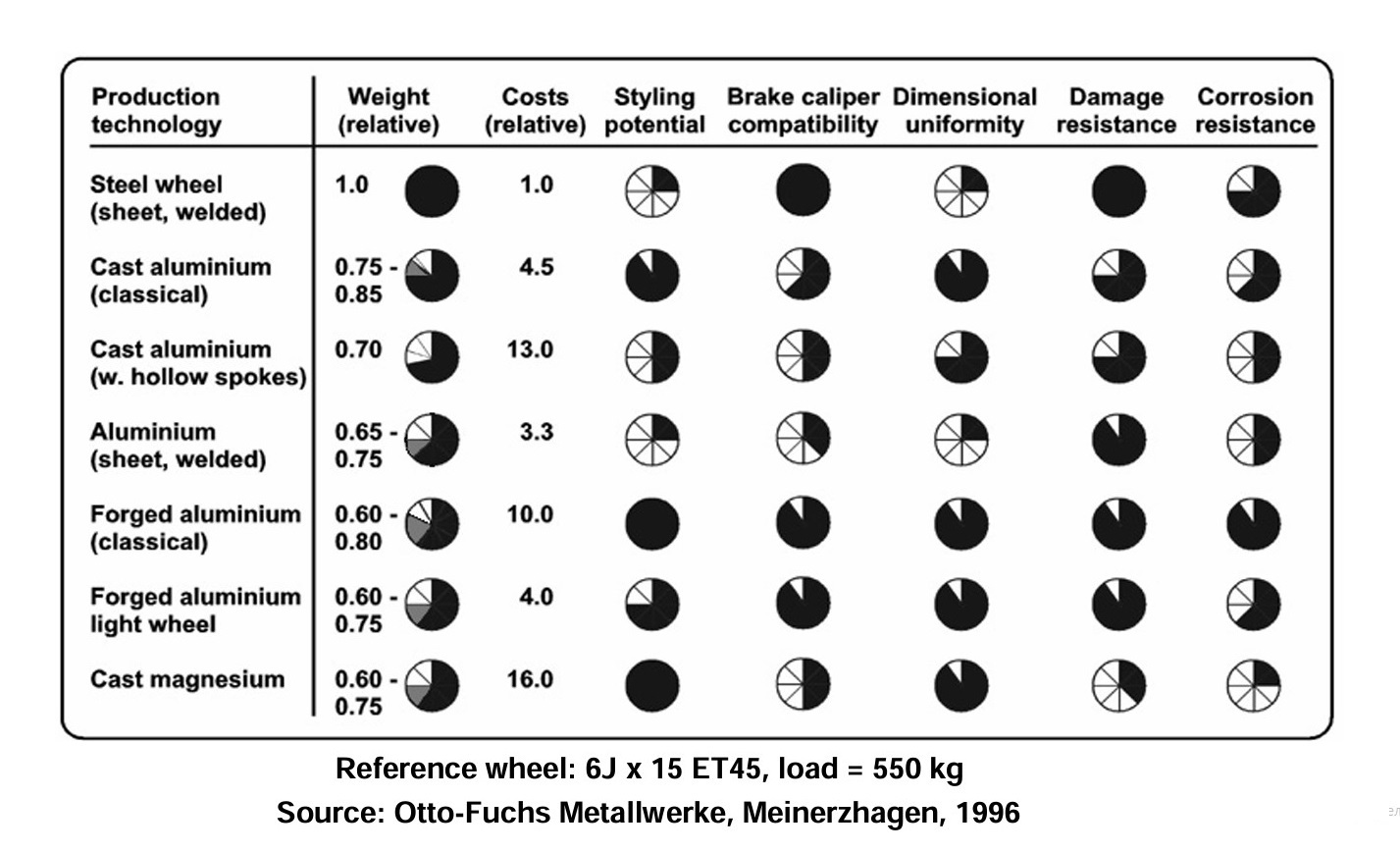

In the design phase of an aluminium wheel, the following characteristics is considered (Figure 2):

- Stiffness

- Static performance (strength)

- Fatigue behaviour

- Crash worthiness

- Thermal aspects

- Style and weight saving potential

- Dimensional tolerances

- Corrosion resistance

Cast aluminium car wheels

The main advantage of cast aluminium wheels is the high styling versatility. Cast wheels also offer a high dimensional accuracy (i.e. homogeneous mass distribution) and adequate static and dynamic mechanical characteristics. An important reason for choosing cast aluminium wheels is their attractive visual appearance. The weight reduction potential compared to steel wheels is a benefit, but often not the major objective.

Forged aluminium car wheels

Forged aluminium wheels are one-piece wheels formed from a single block of metal by hot forging, followed by hot or cold spinning and the necessary machining operations. The forging process permits flexibility in design of the styled disk, almost similar to cast wheels. Onepiece forging is considered superior to other forms of wheel manufacturing in providing ultimate strength while reducing weight compared to cast and multi-piece aluminium wheels. Forged wheels are typically around 25% lighter than cast wheels. While casting may be a less expensive process, cast wheels exhibit significantly lower mechanical properties than forged wheels.

Fabricated car wheels

Fabricated wheels utilize two or three components assembled together to produce a finished wheel. Centres can be either cast or forged. Manufacturing a composite wheel is extremely labour intensive. A one-piece forged wheel requires comparatively higher tooling cost, but the manufacturing process is simpler and faster. Furthermore, in a one-piece forging, all the material serves a structural purpose. Thus, a one-piece wheel will always be somewhat lighter than an equivalent three-piece fabricated wheel. The two-piece wheel design does not offer such a wide range of application as the three-piece wheel, however, two-piece wheels are generally cheaper. Some two-piece wheels have the centre bolted into a cast or cast and spun rim section. Some wheels use forged rims and forged centres. A special type of a two-piece wheel is the sheet wheel. Other aluminium wheel variant is wheels with rims formed from extruded profiles.

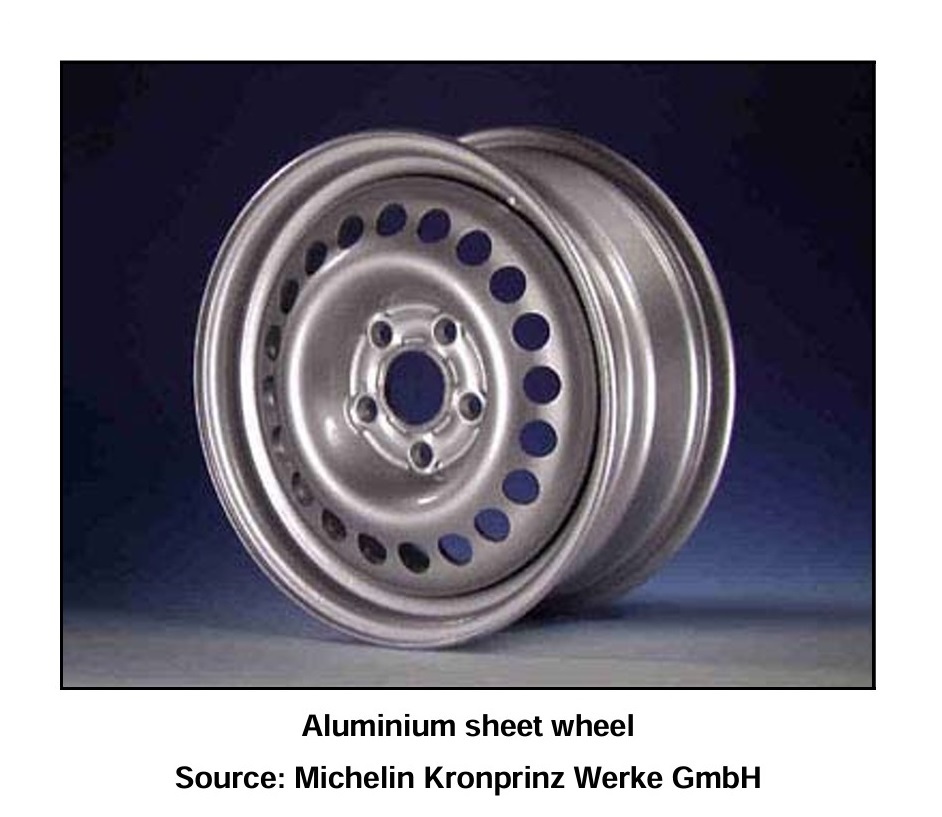

Sheet car wheels

Sheet wheels belong to the lightest types of aluminium wheels. The good mechanical properties and corrosion resistance of aluminium sheet wheels are ensured by the use of established rolled materials. Rim and disc are fabricated from hot rolled AlMgMn alloy sheet stock. This alloy has a stable microstructure resisting thermal effects during service.

The source:

Wheels / Applications // The Aluminium Automotive Manual – The Aluminium Association – 2011