Heat Treatment of Aluminium Alloys

When the term “heat treatment” is applied to aluminium alloys, its use is restricted to the specific operations employed to increase strength and hardness of the precipitation hardenable wrought and cast alloys.

Heat-treatable aluminium alloys

These usually are referred to as the “heat-treatable” alloys to distinguish them from those alloys in which no significant strengthening can be achieved by heating and cooling. The latter, generally referred to as “non-heat-treatable” alloys depend primarily on cold work to increase strength. Commercial wrought alloys whose strength and hardness can be significantly increased by heat treatment include 2xxx, 6xxx, and 7xxx series alloys (Figure 1).

Figure 1

The major aluminium alloy systems with precipitation hardening

The major aluminium alloy systems with precipitation hardening are shown in Figure 2.

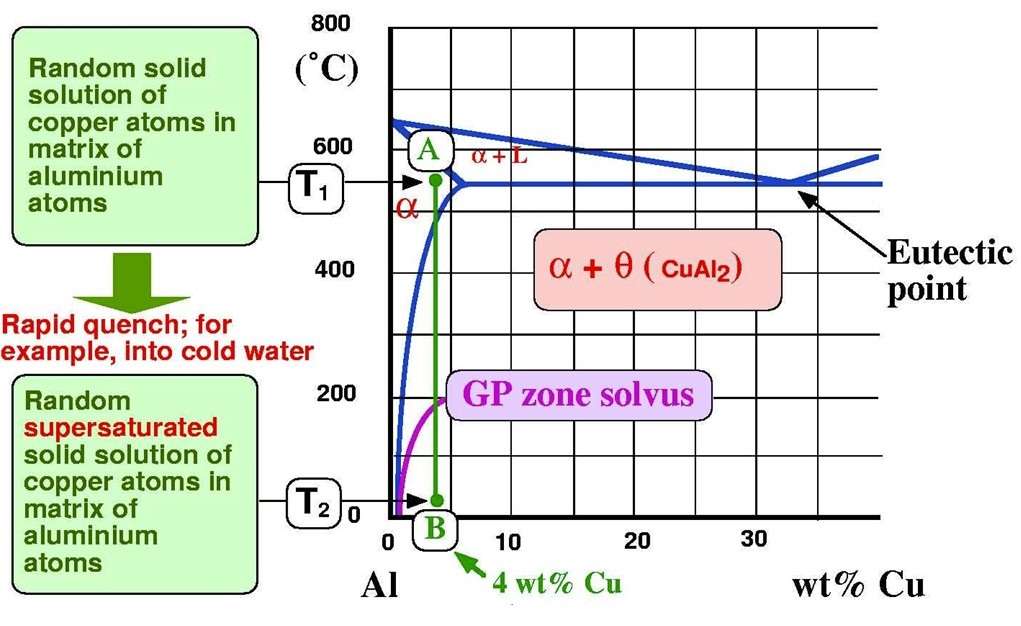

The example of Al-Cu system is shown in Figure 3.

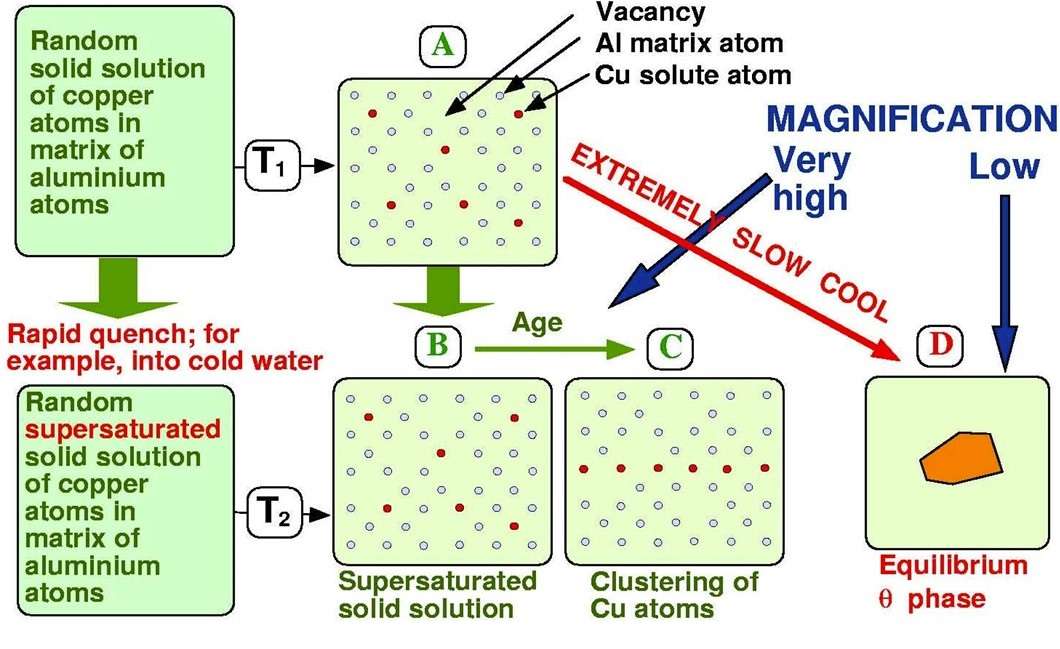

Heat treatment

Heat treatment to increase strength of aluminium alloys is a three-step process (Figure 4):

- Solution heat treatment: dissolution of soluble phases

- Quenching: development of supersaturation

- Age hardening: precipitation of solute atoms either at room

temperature (natural aging) or elevated temperature (artificial

aging or precipitation heat treatment).

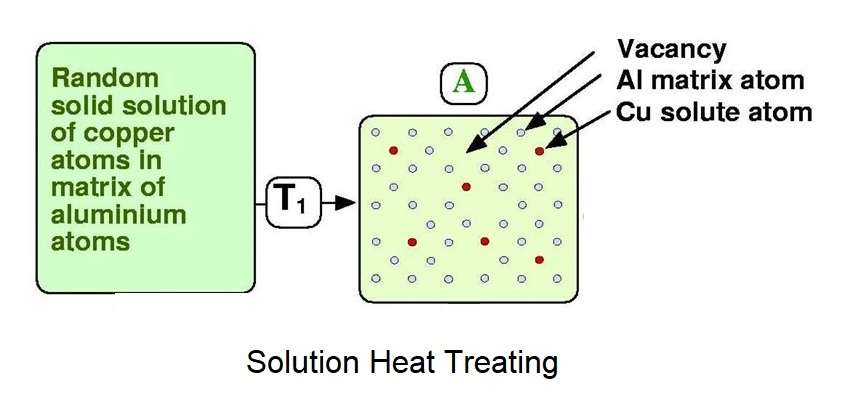

Solution Heat Treating

Its objective is to take into solid solution the maximum practical amounts of the soluble hardening elements in the alloy. The process consists of soaking the alloy at a temperature sufficiently high and for a time long enough to achieve a nearly homogeneous solid solution.

Quenching

Quenching is in many ways the most critical step in the sequence of heat treating operations. The objective of quenching is to preserve the solid

solution formed at the solution heat treating temperature, by rapidly cooling to some lower temperature, usually near room temperature.

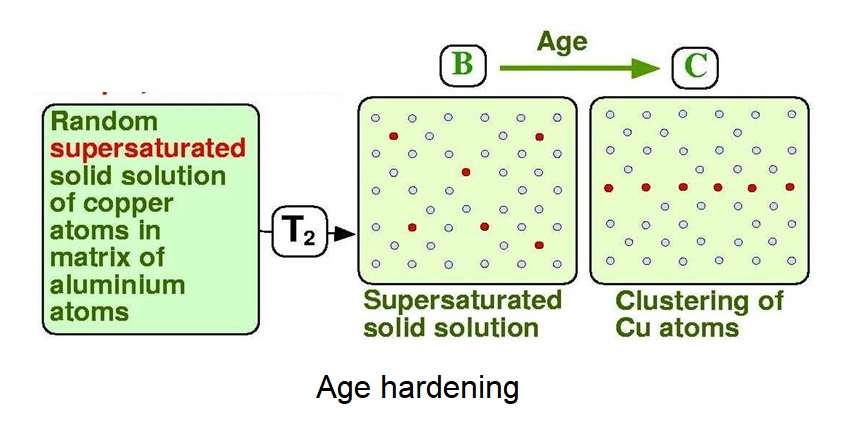

Age hardening

After solution treatment and quenching hardening is achieved either at room temperature (natural aging) or with a precipitation heat treatment (artificial aging).

Natural Aging

The more highly alloyed members of the 6xxx wrought series, the copper-containing alloys of the 7xxx group, and all of the 2xxx alloys are almost always solution heat treated and quenched. For some of these alloys, particularly the 2xxx alloys, the precipitation hardening that results from natural aging alone produces useful tempers (T3 and T4 tempers) that are characterized by high ratios of tensile to yield strength and high fracture toughness and resistance to fatigue.

Artifical ageing

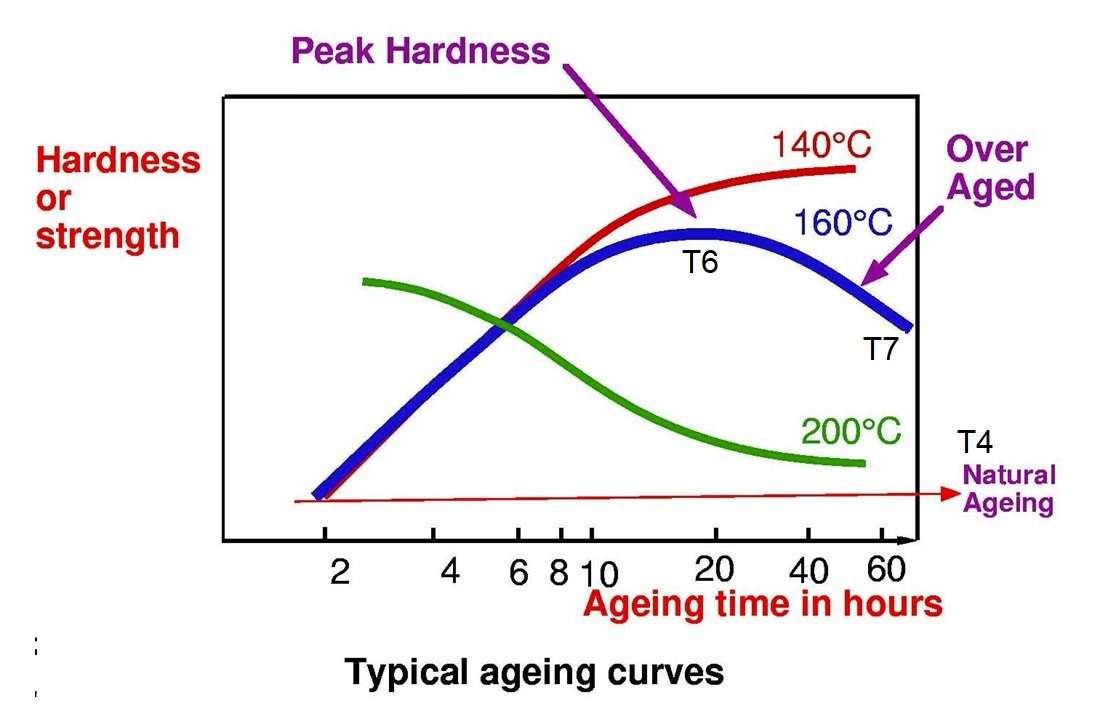

Temperatures range from 115 to 190°C; times vary from 5 to 48 h. Choice of time-temperature cycles for precipitation heat treatment should receive careful consideration. Unfortunately, the cycle required to maximize one property, such as tensile strength, is usually different from that required to maximize others, such as yield strength and corrosion resistance. Consequently, the cycles used represent compromises that provide the best combinations of properties.

Heat-treatment Tempers

Alloys in T6-type tempers generally have the highest strengths practical without sacrifice of the minimum levels of other properties and characteristics

found by experience to be satisfactory and useful for engineering applications. T5 temper occurs when before artificial aging the product receives partial solution treatment or noncomplete quenching.

Alloys in T7 tempers are overaged, which means that some degree of strength has been sacrificed to improve one or more other characteristics. Strength may be sacrificed to improve dimensional stability, particularly in products intended for service at elevated temperatures, or to lower residual stresses in order to reduce warpage or distortion in machining. T7-type tempers frequently are specified for cast or forged engine parts. Precipitation heat-treating temperatures used to produce these tempers generally are higher than those used to produce T6-type tempers in the same

alloys.

The sources:

- Heat Treating / Aluminum and Aluminum Alloys – ASM Speciality Hand Book // Edited by J.R. Davis – 1993

- TALAT lecture 1204 – Precipitation Hardening / M H Jacobs – 1999

- Design of aluminium structures Introduction to Eurocode 9 with worked examples – European Aluminium – 2020