Aluminium casting knowledge

Discover the fundamentals of Aluminium Casting knowledge! Learn about reactions of melt with its environment, oxide skin formation, entrainment processes and surface turbulence.

In the book “Complete Casting Handbook”

Metal Casting Processes, Metallurgy, Techniques and Design

by John Campbell

Selected Contents

Casting Metallurgy

The Melt

- Reactions of Melt with its Environment

- Transport of Gases in Melt

- Surface Film Formation

- Vaporisation

Entrainment

- Entrainment Defects

- Bifilms

- Bubbles

- Extrinsic Inclusions

- Entrainment Processes

- Surface Turbulence

- Oxide Skins from Melt Charge Material

- Pouring

- Oxide Lap Defect I: Surface Flooding

- Oxide Lap Defect II: The Confluence Weld

- The Oxide Flow Tube

- Microjetting

- Bubbles Trails

- Furling and Unfurling

- Deactivation of Entrained Films

- Soluble, Transient Films

- Detrainment

- Evidence for Bifilms

- The Importance of Bifilms

- The Four Common Populations of Bifilms

Flow

- Effect of Surface Films on Filling

- Effective Surface Tension

- The Rolling Way

- The Unzipping Way

- Fluidity

- Fluidity Definition

- Mode of Solidification

- Effect of Velocity

- Effect of Viscosity

- Effect of Solidification Time

- Effect of Surface Tension

- Effect of an Unstable Substrate

- Comparison of Fluidity Tests

- Effect of Vibration

- Extended Fluidity

- Continuous Fluidity

Moulds and Cores

- Moulds: Inert or Reactive

- Transformation Zones

- Evaporation and Condensation Zones

- Mould Atmosphere

- Mould Surface Reactons

- Metal Surface Reactions

- Mould Coatings

Solidification Structure

- Heat Transfer

- Development of Matrix Structure

- Segregation

Casting Alloys

- Zinc Alloys

- Aluminium

- Oxide Films on Al Alloys

- Entrained Inclusions

- Grain Refinement (Nucleation and Growth of the Solid)

- Dendrite Arm Spacing (DAS) and Grain Size

- Modification of Eutectic Si in Al-Si Alloys

- Iron-Rich Intermetallics

- Other Intermetallics

- Thermal Analysis of Al Alloys

- Hydrogen in Al Alloys

- Copper Alloys

- Cast Iron

- Steels

- Nickel-Base Alloys

- Titaniun

Porosity

- Shrinkage Porosity

- Gas Porosity

- Porosity Diagnosis

Cracks and Tears

- Hot Tearing

- Cold Cracking

Properties of Castings

- Test Bars

- The Statistics of Failure

- Effects of Defects

- Tensile Properties

- Fracture Toughness

- Fatigue

- Elastic (Young’s) Modulus and Damping Capacity

- Residual Stress

- High Temperature Tensile Properties

- Oxidation and Corrosion Resistance

- Leak Tightness

- Surface Finish

- Quality Indices

- Bifilm-Free Properties

Casting Manufacture

- Introduction to the Casting Manufacture

Section 1

The 10 Rules for Good Castings

- Rule 1: Use a Good-Quality Melt

- Rule 2: Avoid Turbulent Entrainment (The Critical Velocity Requirement0

- Rule 3: Avoid Laminar Entrainment of the Surface Film (The Non-Stopping, Non-Reversing Condition)

- Rule 4: Avoid Bubble Damage

- Rule 5: Avoid Core Blows

- Rule 6: Avoid Shrinkage Damage

- Rule 7: Avoid Convection Damage

- Rule 8: Reduce Segregation Damage

- Rule 9: Reduce Residual Stress

- Rule 10: Provide Location Points

Section 2 – Filling System Design

Fundamentals

- The Maximum Velocity Requirement

- Gravity Pouring^ The “No-Fall” Conflict

- Reduction or Elimination of Gravity Problems

- Surface Tension Controlled Filling

Components

- Pouring Basin

- Sprue (Down-Runner)

- Runner

- Gates

- Surge Control System

- Vortex System

- Inclusions Control: Filter and Traps

- Filter

Design Practice

- Background to the Methoding Approach

- Selection of a Layout

- Weight and Volume Estimates

- Pressurised Versus Unpressurised

- Selection of a Pouring Time

- Thin Sections and Slow Filling

- Fill Rate

- Pouring Basin Design

- Sprue (Down-Runner) Design

- Runner Design

- Gate Design

Section 3 – Processing (Melting, Moulding, Casting, Solidifying)

Melting

- Batch melting

- Liquid Metal Delivery

- Reverberatory Furnaces

- Crucible Melting (Electric Resistance or Gas Heated)

- Induction Melting

- Automatic Bottom Pouring

- Continuous Melting

- Tower (Shaft) Furnaces

- Dry Hearth Furnaces for Non-Ferrous Metals

- Holding, Transfer and Distribution

- Holder Failure Modes

- Transfer and Distribution Systems

- Melt Treatment

- Degassing

- Detrainment (Cleaning)

- Additions

- Pouring

- Cast Material

- Re-Melting Processes

Moulding

- Inert Moulds and Cores

- Aggregate Moulding Materials

- Binders

- Other Aggregate Mould Processes

- Rubber Moulds

- Reclamation and Re-Cycling Sands

Casting

- Gravity Casting

- Horizontal Transfer Casting

- Counter-Gravity

- Centrifugal Casting

- Pressure-Assisted Casting

- Lost Wax and Other Ceramic Mould Casting Processes

- Lost Foam Casting

- Vacuum Molding (V Process)

- Vacuum-Assisted Casting

- Vacuum Melting and Casting

Controlled Solidification Techniques

- Conventional Shaped Casting

- Directional Solidification

- Single Crystal Solidification

- Rapid Solidification Casting

Dimensional Accuracy

- The Concept of Net Shape

- Mould Design

- Mould Accuracy

- Tooling Accuracy

- Casting Accuracy

- Metrology

Post-Casting Processing

- Surface Cleaning

- Heat Treatment

- Hot Isostatic Pressing

- Machining

- Painting

- Plastic Working (Forging, Rolling, Extrusion)

- Impregnation

- Non-Destructive Testing

Several pictures from this book that refer to aluminium

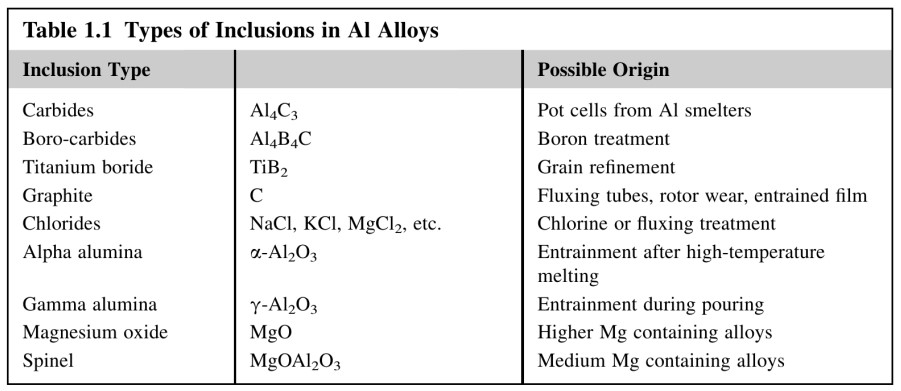

To Table 1.1 – Nearly all of these foreign materials will be deleterous

to products intended for such products as foil or computer discs.

However, for shaped casting, those inclusions such as carbides and borides

may not be harmful at all. This is because having precipitated from melt,

so they are usually therefore in excellent atomic contact with matrix.

Figure 2.1 – Sketch of a surface entrainment event

Figure 2.1 – Sketch of a surface entrainment event

Figure 2.4 – Entrainment defects:

Figure 2.4 – Entrainment defects:

(a) a new bifilm; (b) bubles entrained as an integral part of the bifilm;

(c) liquid fluxtrapped in a bifilm; (d) surface debris entrained with the bifilm;

(e) sand inclusions entrained in the bifilm;

(f) an entrained surface film contained integral debris