Friction Welding of Aluminium

Friction welding

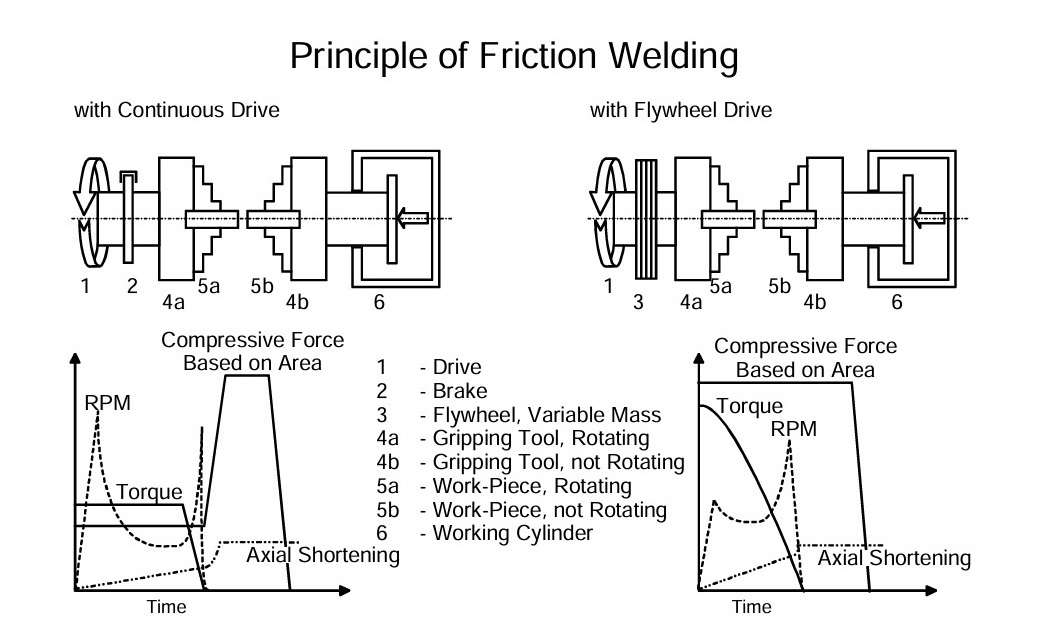

Friction welding is a process in which mainly rotationally symmetrical parts are rotated while being pressed together, thereby generating heat of friction which causes the parts to weld. There are two main variations of this process: friction welding with a continuously applied drive and friction welding using a flywheel drive. Characteristic for the continuous drive is an externally applied brake. The flywheel drive, on the other hand, delivers its stored energy to the process thereby slowing down itself. Consequently, this leads to differences in behaviour of the two methods regarding torque and the compressive force being brought to bear.

Figure 1 – Principle of friction welding

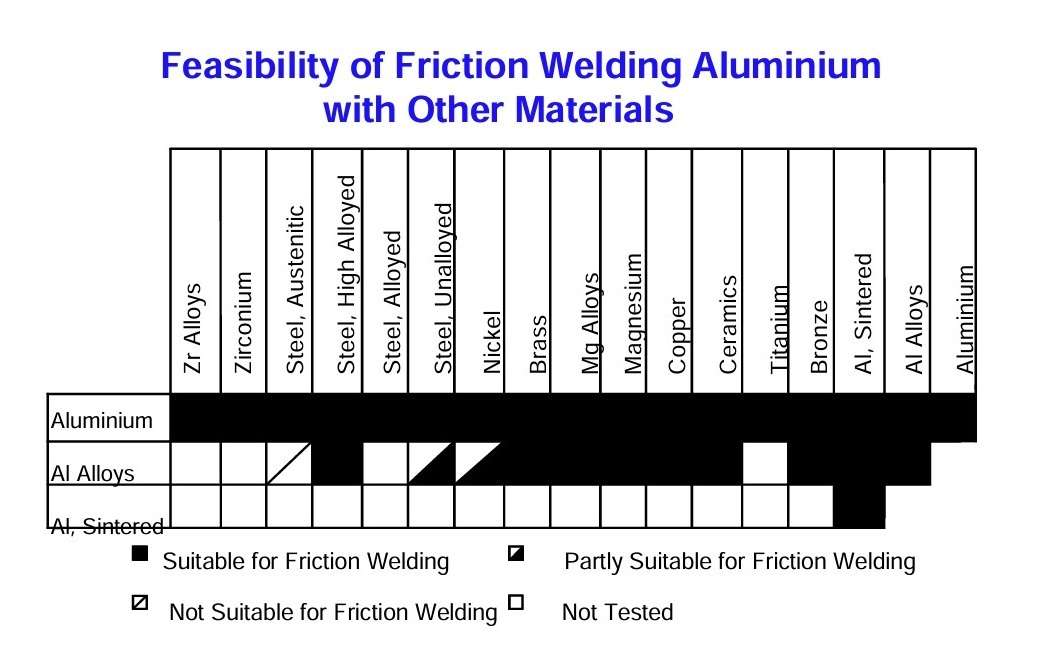

The material data alone are not sufficient to indicate whether friction welding can be successfully employed. Consequently, a number of alloys which cannot be welded by other welding processes, can be welded effectively using friction welding. Parts to be joined by the friction welding process, must have a sufficiently high strength to be able to transmit the axial pressure and frictional moment as well as a sufficient hot forming capacity. Pure aluminium is ideally suited for friction welding. Out of the large number of aluminium alloys and powder metallurgical materials available, there are still some whose suitability for welding has still to be tested.

Figure 2 – Feasibility of friction welding aluminium with other materials

Figure 2 – Feasibility of friction welding aluminium with other materials

The following disadvantages limit the applicability of friction welding:

- The creation of low-melting phases or brittle intermetallic compounds.

- The softening of aged alloys.

- The amount and distribution of non-metallic inclusions.

- Hardening effects of the material combinations.

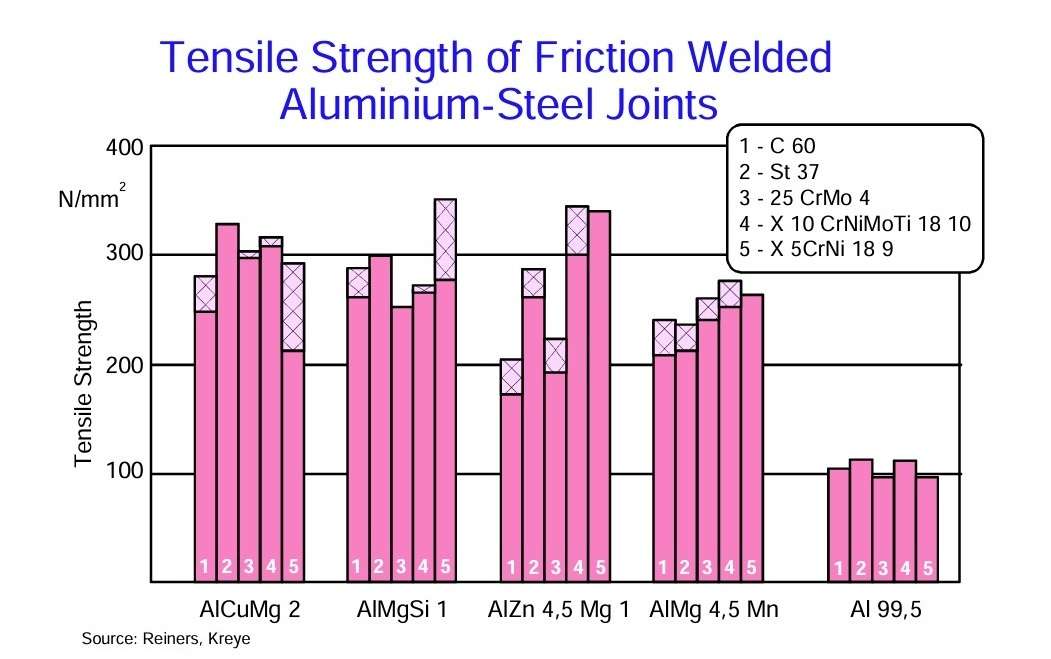

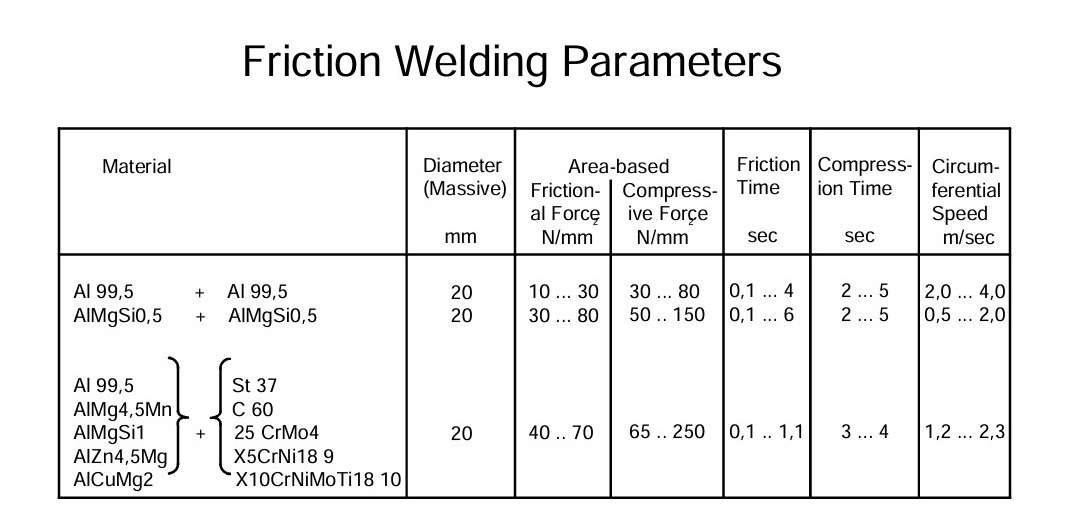

Experiments with friction welding on different aluminium and steel alloys (for parameters see this figure) have shown that strengths exceeding the yield stress of aluminium and steel can be attained. There is no straightforward correlation between strength of alloys and strength of friction welded joints. Consequently, one can assume that other factors play an important role here. Such composite joints exhibit brittle fractures with little plastic strain at the joining plane. This is a result of the different mechanical properties of steel and aluminium. The resulting inhibition of plastic deformation at the contact surface which occurs under the influence of multi-axial state of stresses leads to the preferential building of cracks at these sites.

Figure 3 – Tensile strength of friction welded aluminium-steel joints

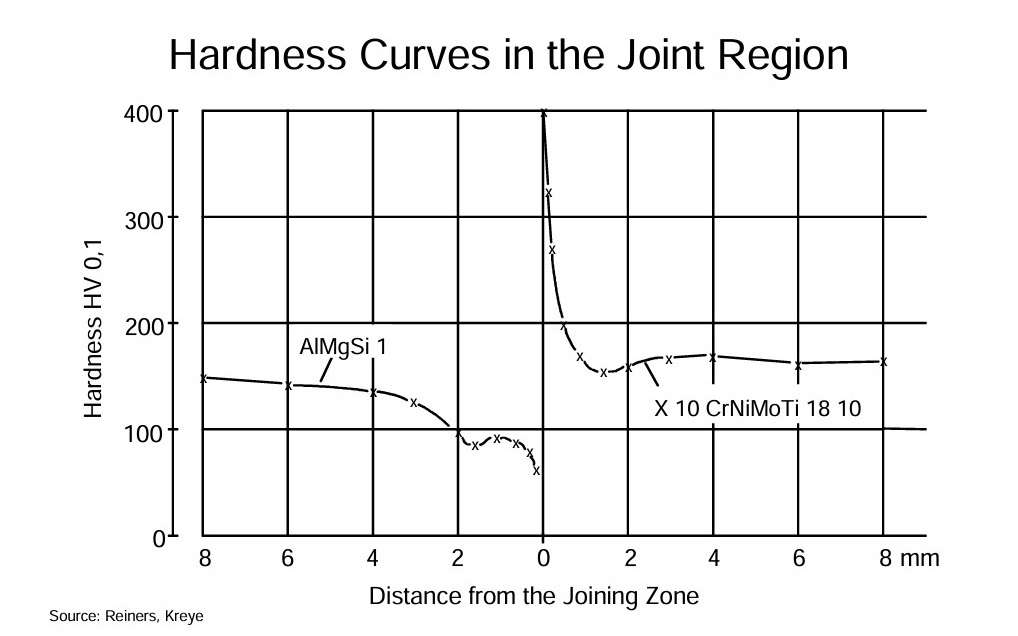

The short welding times lead to correspondingly high hardness values. For aluminium joints this is less of a problem than for composite joints of aluminium with steel. The very narrow bonding plane, characteristic for the process, shows hardness peaks only in a region of 100 to 200 µm. Austenitic steels have a higher strain hardening coefficient than ferritic steel and therefore reach higher hardness values. In heat-treatable alloys the precipitates can go into solution, causing a softening of the alloy. In heat-treatable alloys which respond to natural ageing, a precipitation of the hardening particles occurs at room temperature, causing the hardness to rise again.

Figure 4 – Hardness curves in the joint region

Figure 4 – Hardness curves in the joint region

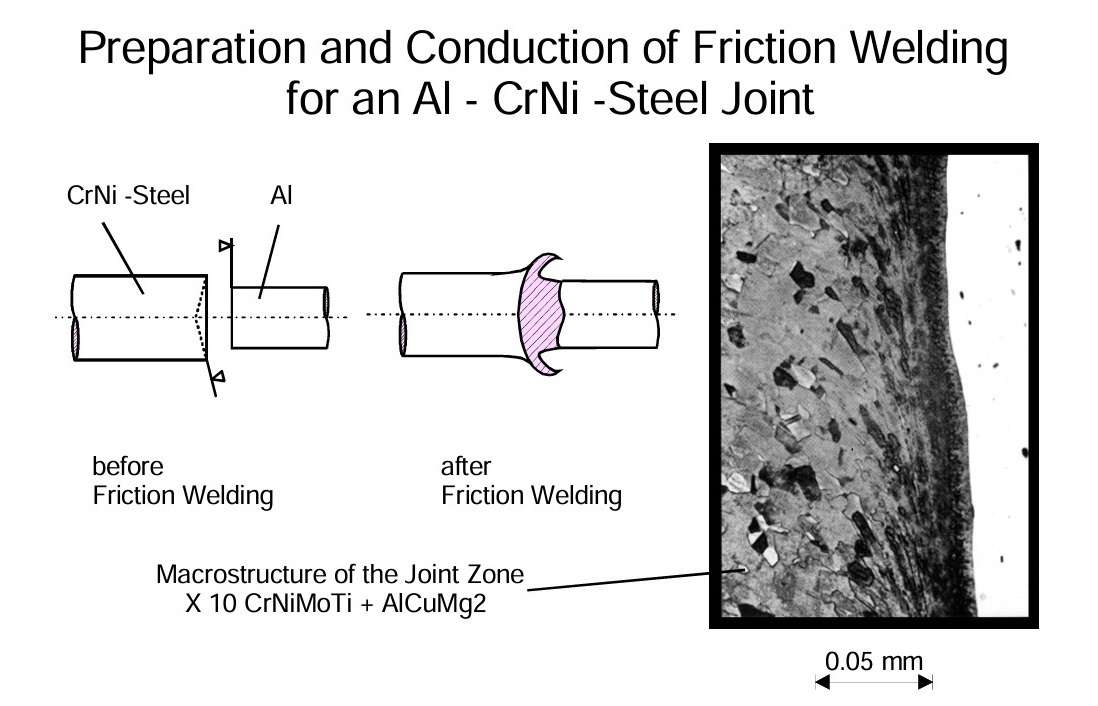

The different thermal properties of the materials have to be taken into account while preparing the welds. The surface area of materials with a low thermal conductivity should be increased, in order to deliver a joining zone with good properties. In this region, the grains are highly deformed.

Figure 5 – Preparation and conduction of friction welding for Al-CrNi-steel joint

Figure 5 – Preparation and conduction of friction welding for Al-CrNi-steel joint

Friction welding of aluminium with itself and its alloys as well as with steel is characterised by extremely short welding times and high frictional and compressive forces. As a result, the joining plane is kept extremely narrow, so that intermetallic compounds and phases cannot be built. The diffusion zone characteristic for this region is thus kept very small (< 1µm). Short friction times for aluminium are only relevant in connection with a rapidly increasing force the friction and compressive phases.

Figure 6 – Friction welding parameters

Figure 6 – Friction welding parameters

The source:

TALAT Lecture 4400 – Friction, Explosive and Ultrasonic Welding Processes of Aluminium / Ulrich Krüger – European Aluminium Association – 1994