Foundry aluminium alloys

Unlock the potential of foundry aluminium alloys in casting. Gain insights into their composition, properties, and applications.

An casting is the product at or near finished shape, formed by solidification of the metal in a mould or a die. Castings are made in special casting plants called foundries. Special aluminium casting alloys for the production of castings are usually called foundry aluminium alloys.

The types of aluminium foundry alloys

A large number of aluminium alloys has been developed for casting. Most of them are varieties of six basic types:

- aluminium copper

- aluminium-copper-silicon

- aluminium-silicon

- aluminium-magnesium

- aluminium-zinc-magnesium

- aluminium-tin.

Aluminium-copper casting alloys

- Contain 4 to 5% of copper and small impurities of iron, silicon and magnesium.

- Are heat-treatable.

- Can reach yeld strengh of 450 MPa.

- After quenching slowly harden at room temperature for several days.

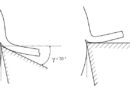

- Have poor castability.

- Require very careful gating.

Aluminium-copper-silicon alloys

- The most widely used aluminium casting alloys.

- Contain silicon together with copper.

- The copper predominates in some alloys and silicon in others.

- The copper contributes to strength.

- The silicon improves castability and reduces hot shortness.

- The higher silicon alloys are used for more complex castings and for permanent mold and die casting processes.

Aluminium-silicon alloys

- Do not contain copper.

- Silicon gives good castability, weldability and good corrosion resistance.

- It is possible to produce castings in complex shape.

- Magnesium additions make these alloys heat-treatable.

- Silicon content usually is between 5 and 13%.

- Have high fluidity and suitable for sand or die casting

- The strength and ductility of these alloys is improved by so called “modification”.

- Modification is achieved through the addition of a controlled amount of sodiom or strontium that refines the silicon eutectic.

Aluminium-magnesium alloys

- Contain 2 to 5% magnesium and 0,1 to 0,4% manganese.

- Have good weldability.

- Have good corrosion resistance, ecpecially to seawater and marine atmospheres.

- The relative poor castability.

- Require a low inpurity content. Must be prepared from high quality metals.

- The tendency of the magnesium to oxidize.

Aluminium-Zinc-Magnesium alloys

- Contain 2 to 8% zinc, 0,5 to 4% magnesium, and 0 to 3% copper.

- The total amount of zinc, and copper controls the properties and uses.

- Have the ability to naturally age. Full strength is achieved at room temperature 2 to 3 week after casting. This process is accelerated by furnace ageing.

Aluminium-tin alloys

- Contain about 6% tin and also a small amount of copper and nickel for improving strength.

- Good castability.

- Used for cast bearings because of tin’s high lubrication charactristics.

Source: