How forged aluminum gets its fiber structure

Aluminium forgings were first used about 60 years ago for the aerospace industry. Since then, there has been a rapid increase of their use in other fields of application. Aluminium forgings are used predominantly in the transport industry, where weight savings lead to savings in fuel consumption.

Aluminium forgings provide the following advantages:

- high strength and low weight,

- good corrosion resistance (for most aluminium alloys),

- the fibre (grain) structure can be arranged to correspond to the main loading direction leading to high strength and fatigue properties.

According to the characteristic differences in free forming (or unrestricted forming) and die forming (restricted forming), forging can be divided into open-die forging and die forging.

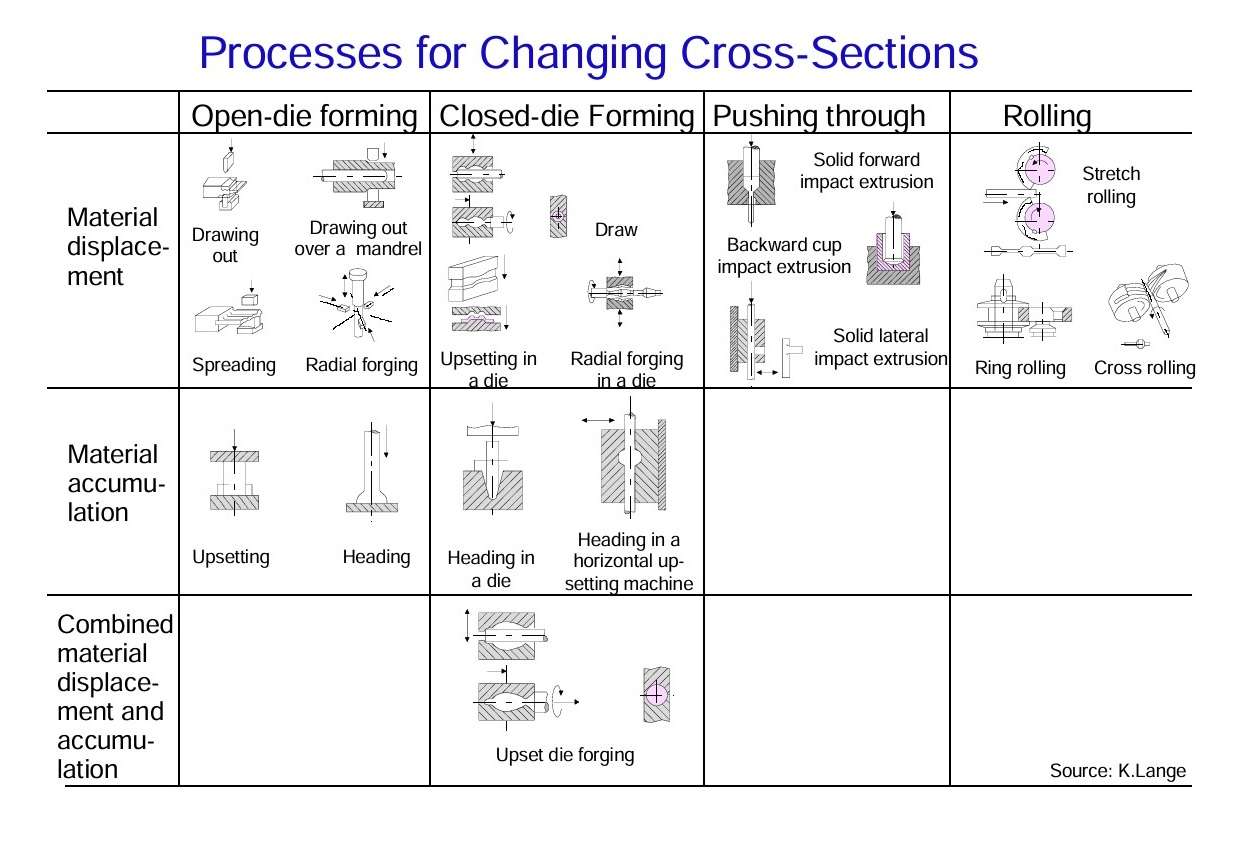

Processes for Changing Cross-Sections

The processes for changing cross-sections build-up the fundamentals of forging. According to the law of constant volumes, changes in cross-section lead to corresponding changes in length. The cross-section can be changed by material displacement and material accumulation, whereby the processes of material displacement dominate.

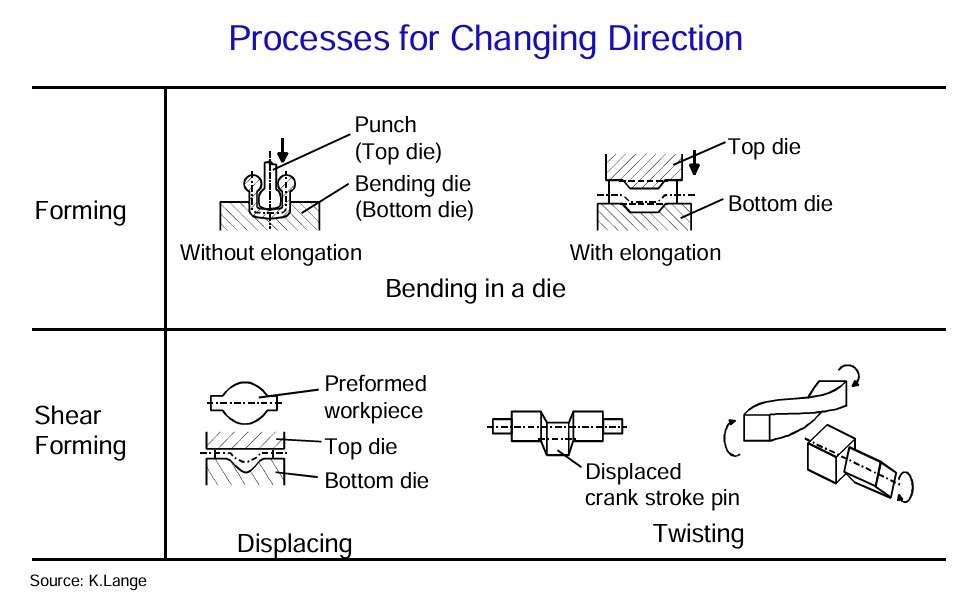

Processes for changing direction

These processes include bending processes (free bending, die bending) and shear forming processes.

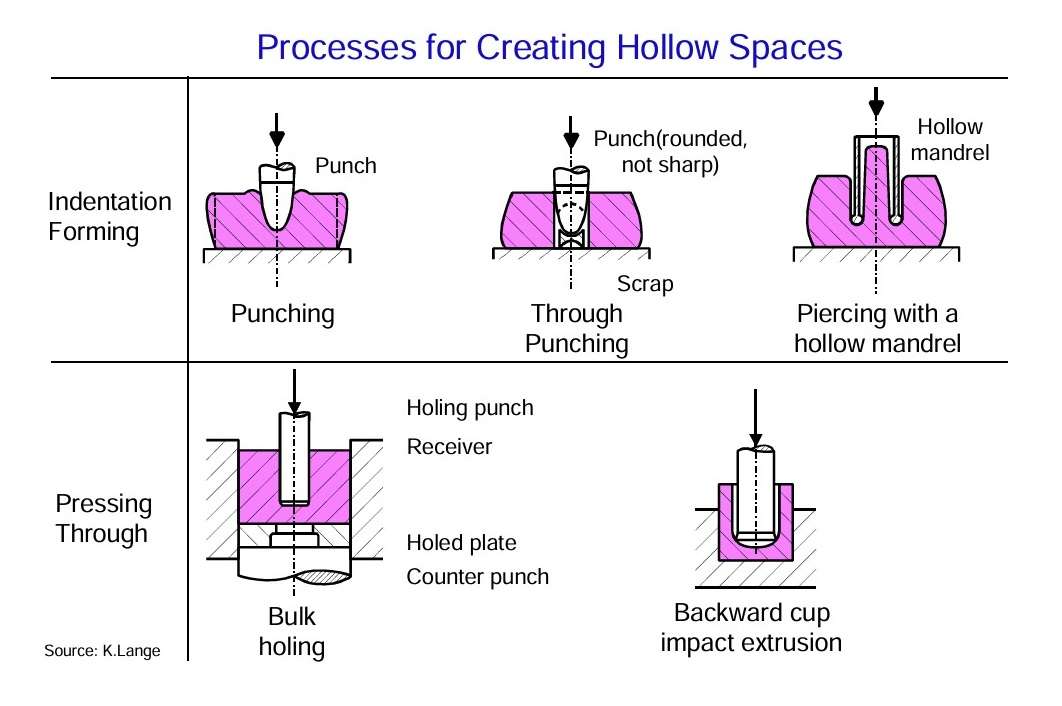

Processes for Creating Hollow spaces

Hollow spaces (cavities) are produced by the methods of indentation forming and extrusion forming.

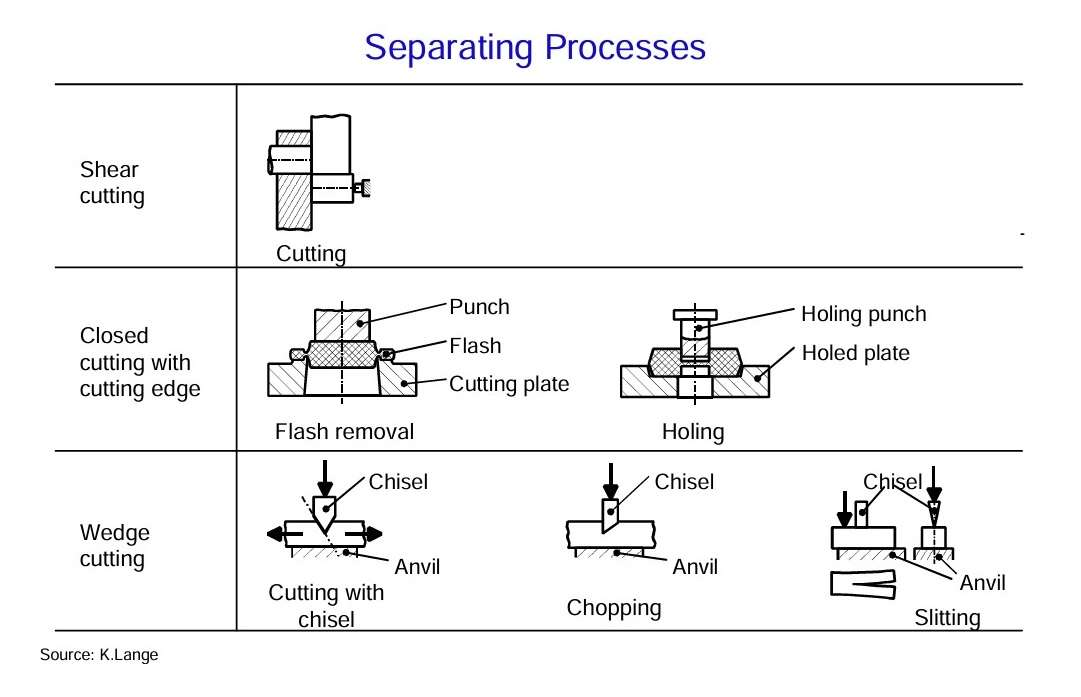

Separating Processes

Separating processes used for forging are mostly cutting processes. Shear cutting processes are used for the loss-free cutting of raw parts with a given cross section (extruded sections) and defined lengths or volumes.

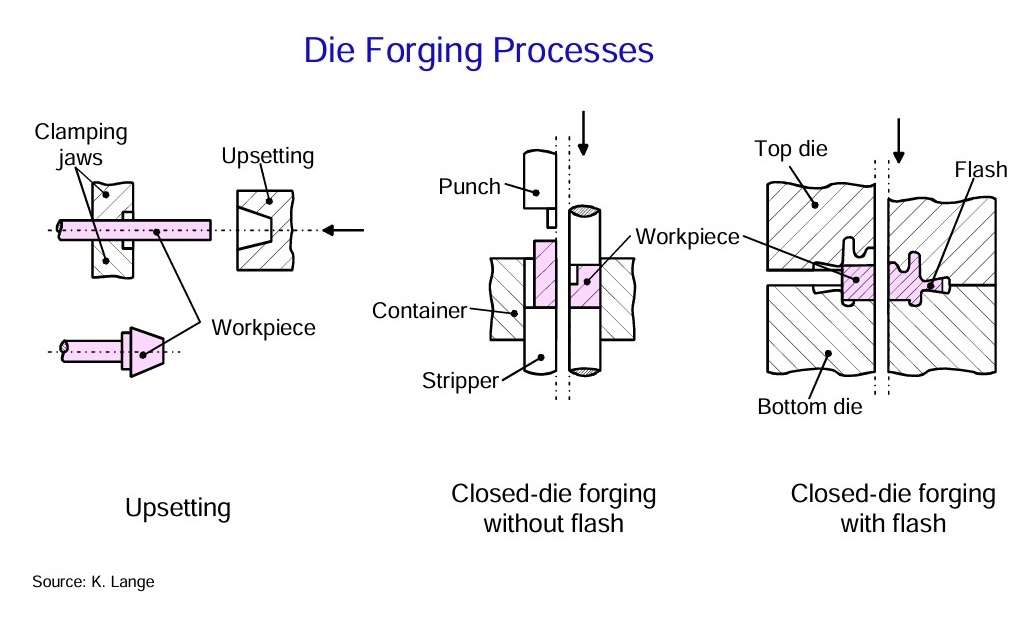

Die Forging Processes

These are processes which are used to produce a defined workpiece geometry having good dimension and volume accuracy. Such processes are: form pressing with flash, form pressing without flash and compressing in a die.

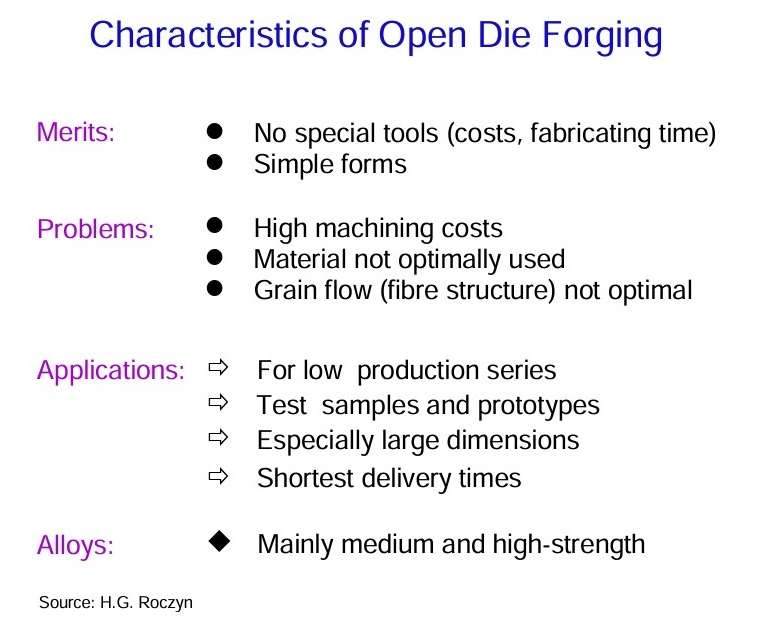

Open-Die Forging

The chacteristics of open-die forging are listed in this figure.

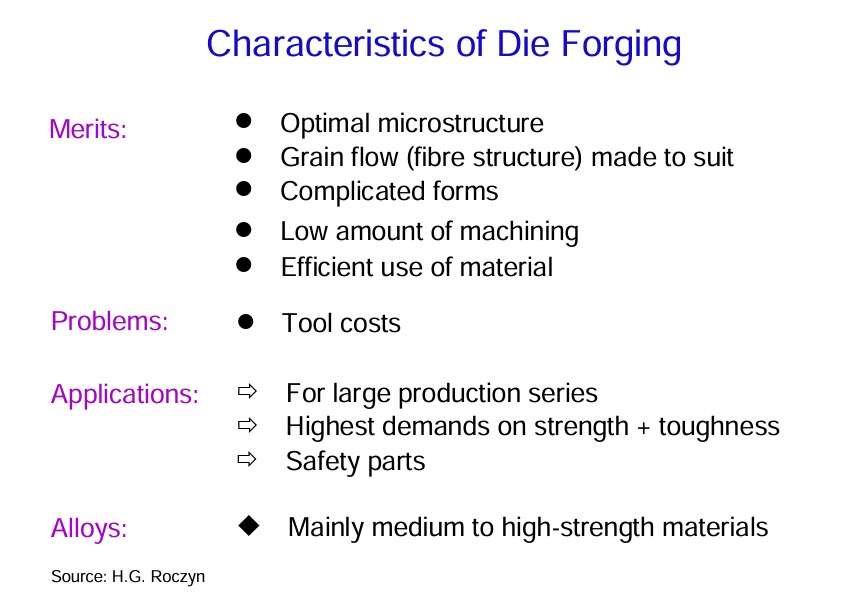

The Characteristics of Die Forging

The characteristics of die forging are listed in Figure 8.

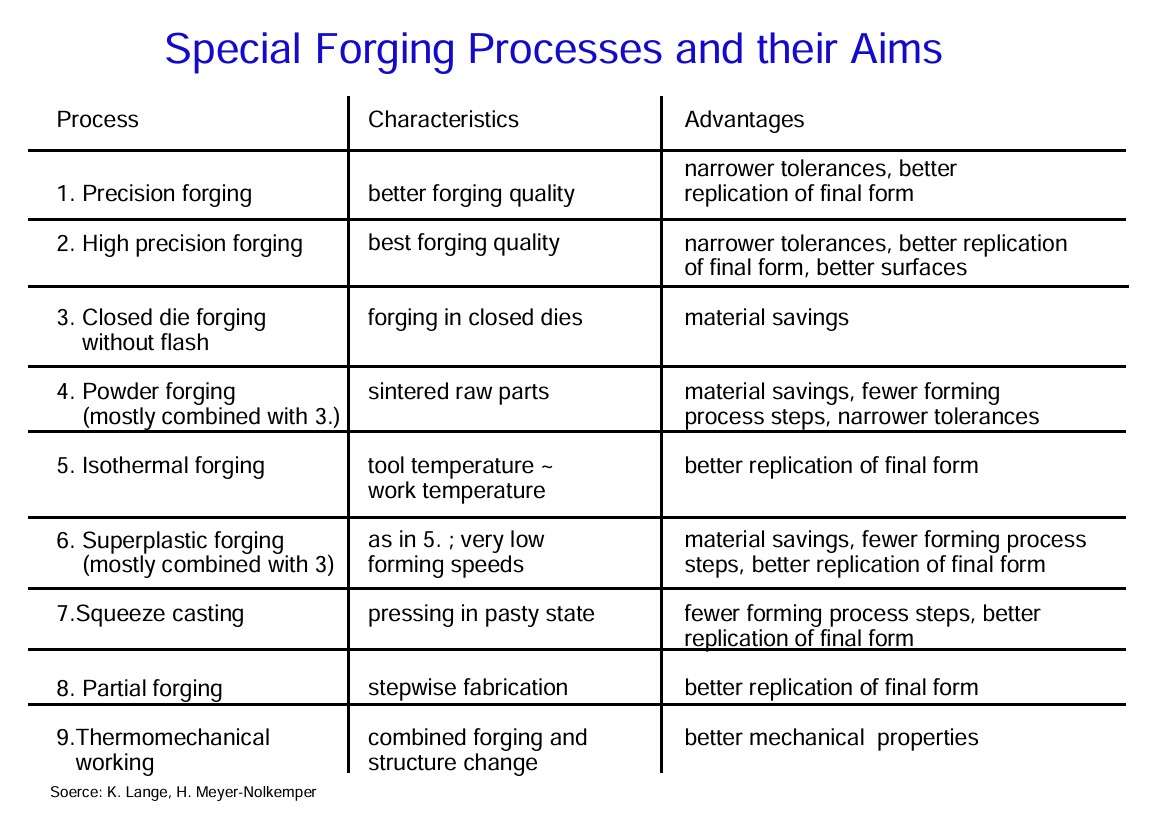

Various Special Die Forging Processes

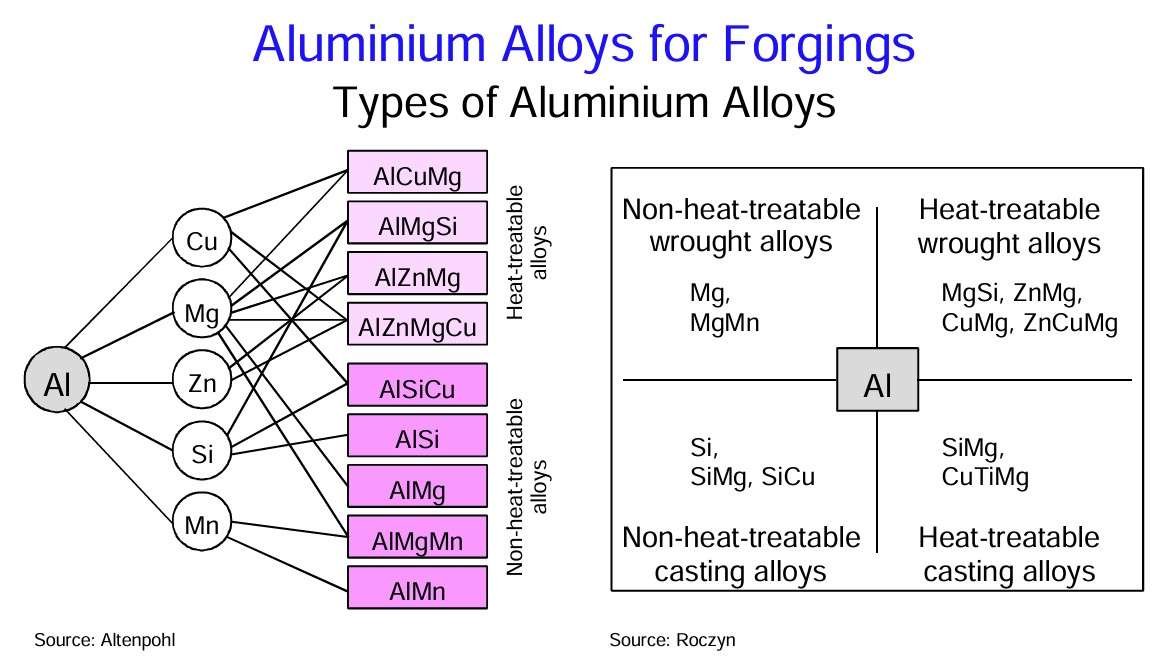

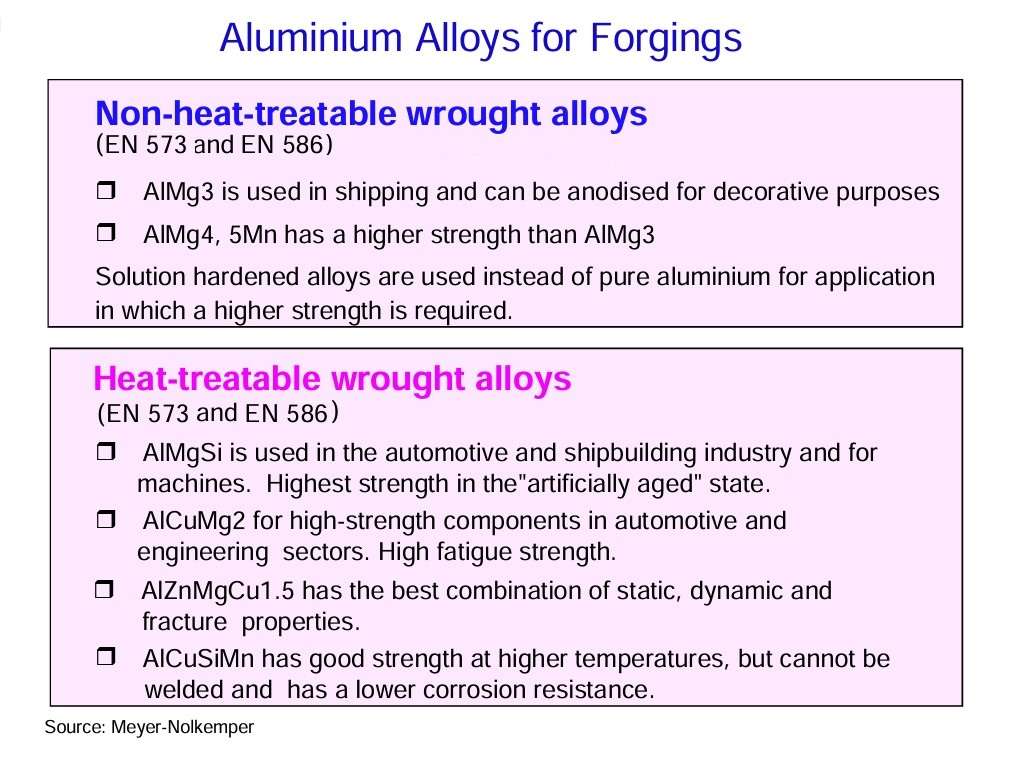

There are various special die forging processes. A large number of aluminium alloys, ranging from pure aluminium up to the highstrength aluminium alloys, can be forged effectively. All alloys standardised in the EN 573 and EN 586 may be used. Forgings are mainly used for structural engineering parts, so that aluminium forging alloys are mostly of the heat-treatable type with medium to high strength.

The strength of pure, unalloyed aluminium Al99,5 is only 65 N/mm² and thus too low for many technical applications. For such purposes one uses aluminium alloys based on Al99,5 with additions of one or more alloying elements. The so-called high-strength aluminium alloys have tensile strengths exceeding 600 N/mm².

The advantages of aluminium forgings:

- high strength and low weight

- good corrosion resistance

- the fibre (grain) structure.

The sources:

- TALAT Lecture 3402 – Forging Process / K. Siegert, R. Malek and R. Neher – European Aluminium Association – 1994

- TALAT Lecture 3401 – Forging Alloys / K. Siegert, A. Möck and R. Neher – European Aluminium Association – 1994