Electron Beam Welding of Aluminium

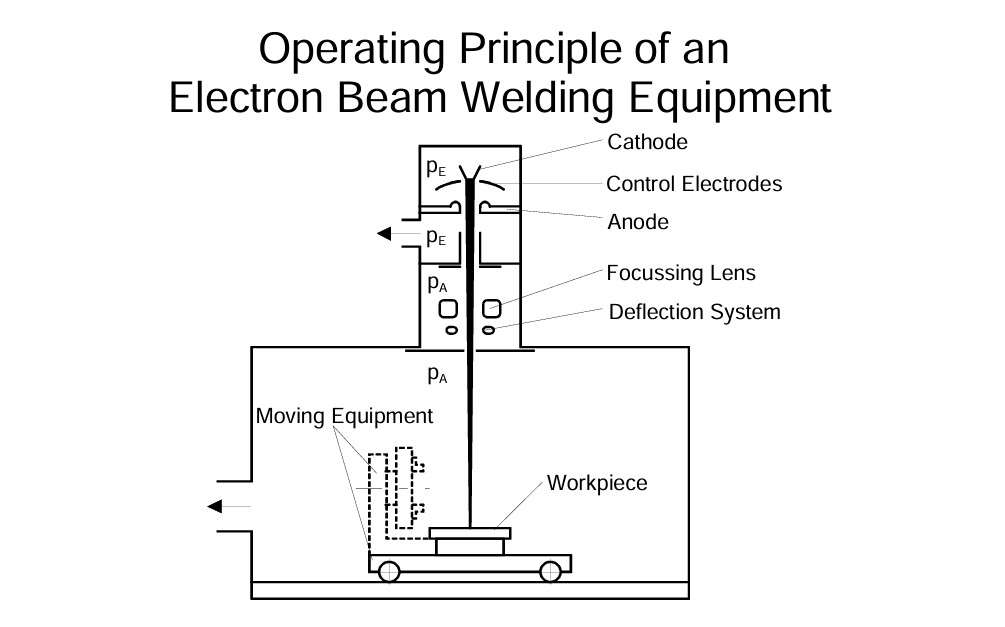

Operating Principle of an Electron Beam

Welding Equipment

The electron beam welding is associated with energy densities of more 108 W/cm2. A vaporisation of the metal occurs above 106. The electrons emitted from an incandescent electrode and accelerated in an electron gun are focussed to bombard the work placed in a vacuum chamber. An arrangement of deflecting systems is used to make the beam move. The work can also be moved along different axes, so that the welding location is accessible. Welding can be carried out with or without a filler metal.

Figure 1 – Operating principle of an electron beam welding equipment

Figure 1 – Operating principle of an electron beam welding equipment

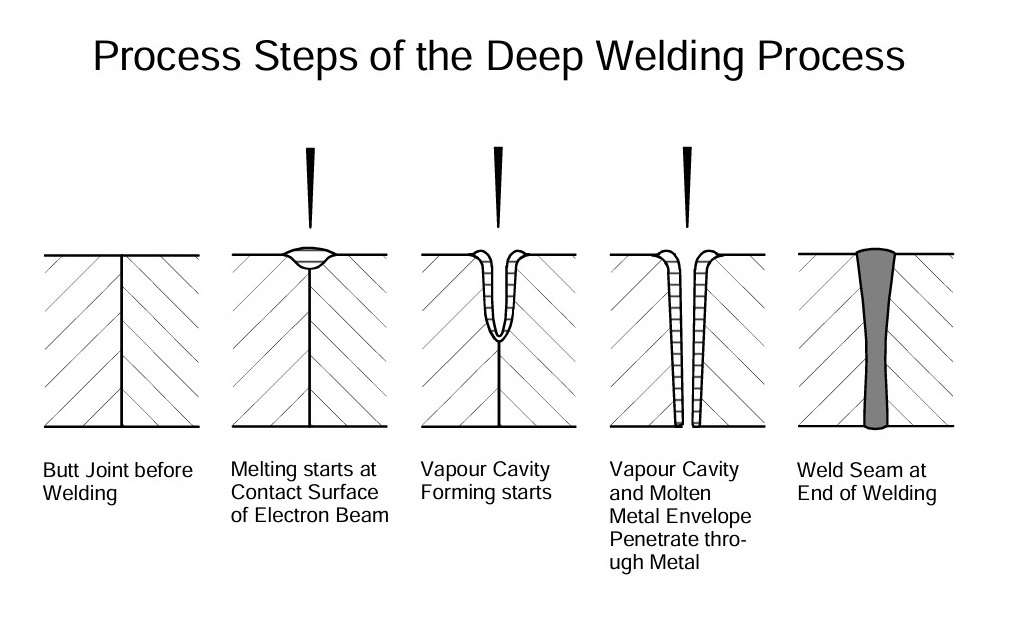

Process Steps of the Deep Welding Process

The formation of a vapour cavity or deep-weld effect is typical for beam welding processes. A cavity consisting of a vapour core surrounded by molten metal is created. The beam can thus penetrate through the whole thickness of the metal. Vapour pressure and surface tension have a two-fold effect: they keep the cavity open towards the top and thus allow an unhindered beam penetration and at the same time allow the weld pool to flow together or allow a crystallisation in the beam vicinity. Care must be taken to ensure that the vapour cavity exists long enough for degassing to occur so that the weld porosity is eliminated or kept to a minimum.

Figure 2 – Process steps of the deep welding process

Figure 2 – Process steps of the deep welding process

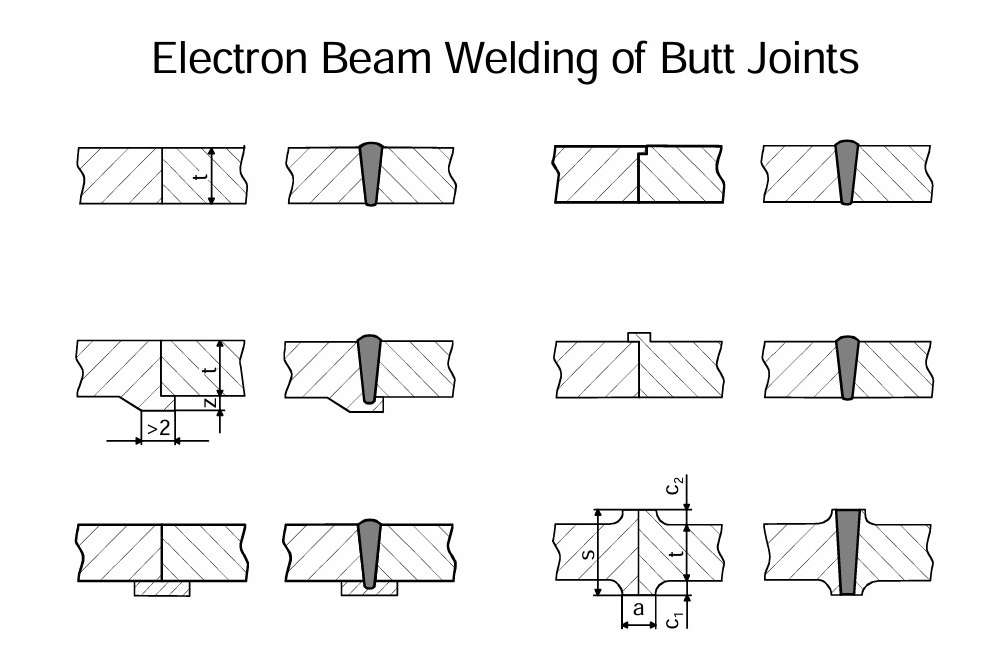

Electron Beam Welding of Butt Joints

The surfaces to be joint are mechanically worked or, as in the case of extrusions, have especially formed lips which help to position the parts to be welded and serve as weld pool supports. Weld pool supports in the form of grooved sections are usually not used, since the high energy beam reaches right through to the bottom of the joint. This would lead to an undesired welding. The remaining weld-pool supports tend to reduce the dynamical strength. For this purpose, joint forms and machining allowances are designed.

Figure 3 – Electron beam welding of butt joints

Figure 3 – Electron beam welding of butt joints

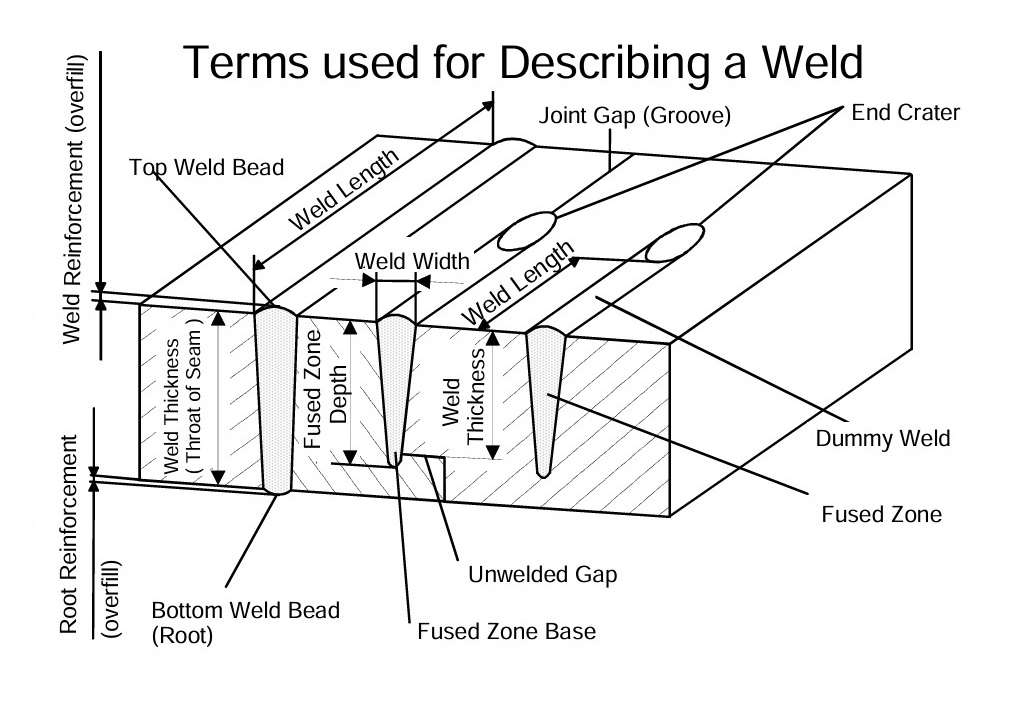

Terms used for describing a weld.

Joints made by the electron beam welding process are characteristically extremely narrow and deep. The ratio of weld thickness (throat of seam) to weld width lies between 5:1 to 25:1. Thus it is possible to weld even thick sheets with a square butt joint with the electron beam welding process where the other welding processes would require large V-angles and filler metal. Figure 4 shows terms used for describing a weld.

Figure 4 – Terms used for describing a weld

Figure 4 – Terms used for describing a weld

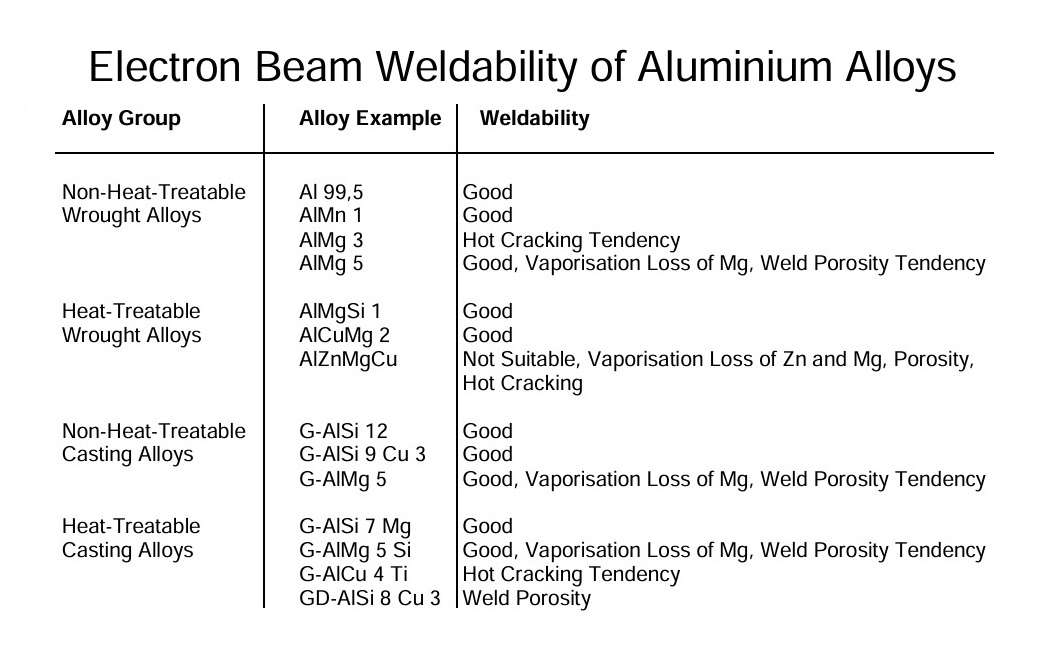

Electron beam weldability of alumnium alloys

Generally, aluminium and its alloys can be welded easily with the electron beam welding process. Among the non-heat-treatable alloys, the hot-cracking tendency increases with increasing magnesium content. At the same time, the high vapour pressure of magnesium increases the danger of porosity in welds. The cracking tendency depends on the contents of magnesium and silicon. As far as possible, the alloy AlMg3 should be avoided. The heat-treatable alloys have only a limited suitability. Due to the reduced heat input, the alloys containing copper can be easily welded. It is known that the weldability of copper-containing alloys with other welding processes is poor.

Figure 5 – Electron beam weldability of aluminium alloys

Figure 5 – Electron beam weldability of aluminium alloys

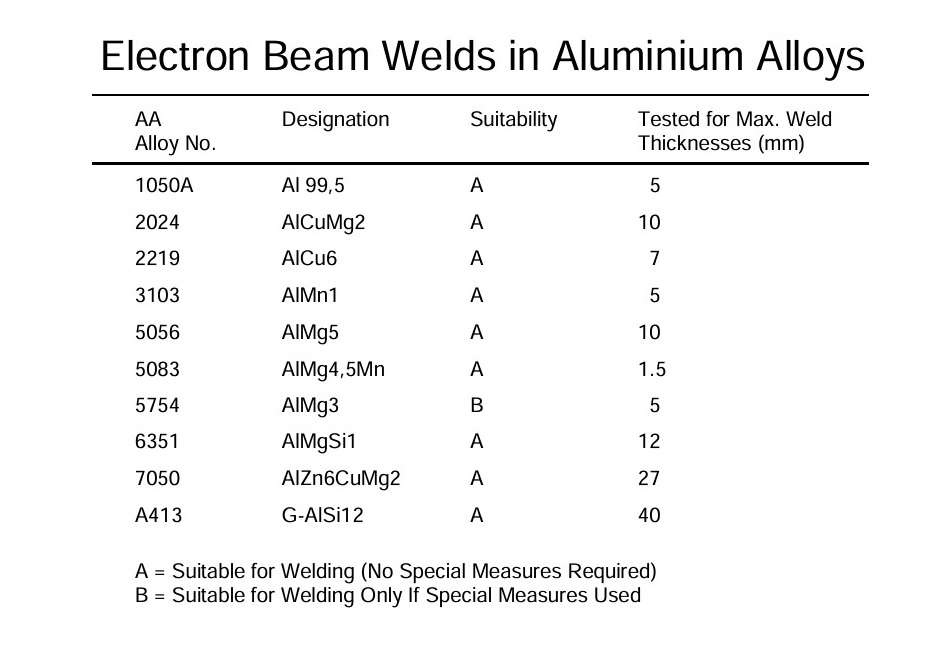

Practical experience with electron beam welding

Practical experience with electron beam welding exists for a number of aluminium alloys. Materials up to 40 mm in thickness can be welded. Even here, experience shows that AlMg3 alloys can be welded only by adhering to special measures. An explanation for the hot cracking tendency lies in the fact that the beam with its high energy density causes a relatively high amount of magnesium to vaporise so that the remaining content now lies in the range of 1,5%. It is just this magnesium content which causes a maximum amount of cracking.

Figure 6 – Electron beam welds in aluminium alloys

Figure 6 – Electron beam welds in aluminium alloys

Source:

TALAT Lecture 4300 – Beam Welding Processes of Aluminium / Ulrich Krüger – European Aluminium Association, 1994