Design of Adhesive Metal Joints

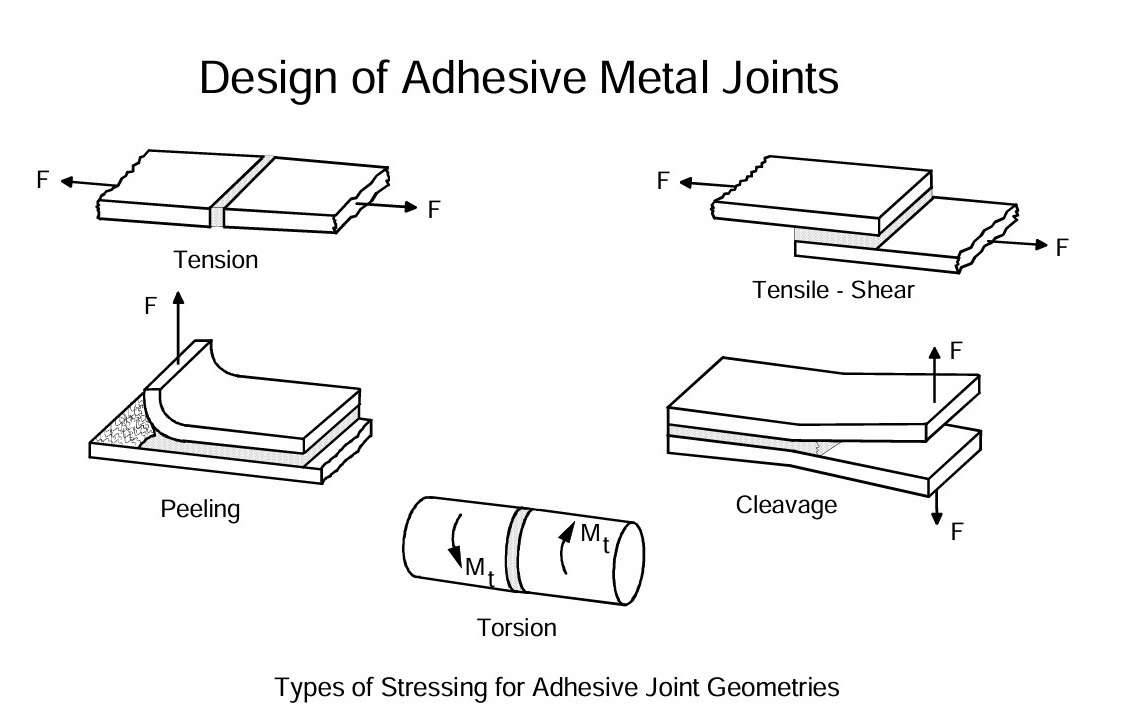

Basic Types of Loadings of Adhesive Joint Geometries

The adhesive joint has to be specially optimised for adhesive joining in order to have a joint of optimal strength. Of the possible loading types which an adhesive joint can be subjected to, it is most suited for shear, torsion and compressive loads. Tensile and in particular cleavage or peeling forces should be avoided.

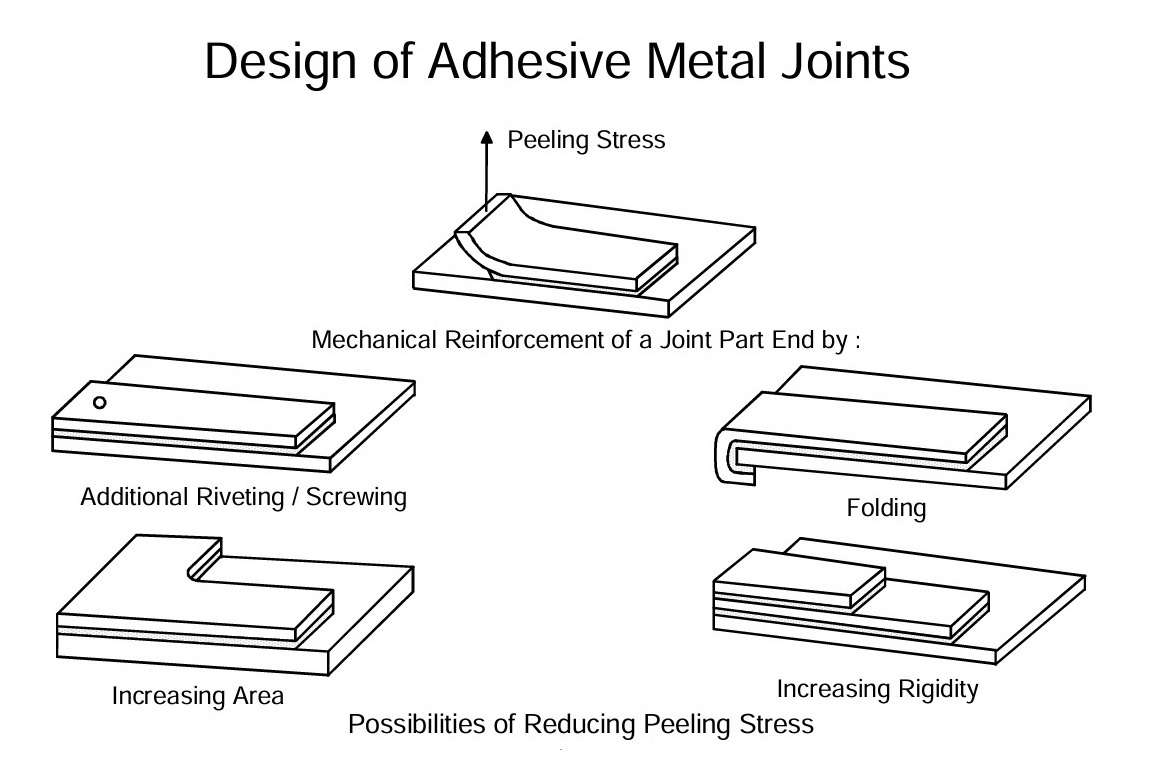

Design types

Design types which avoid peeling stresses in adhesive joints of metals are illustrated in Figure 2.

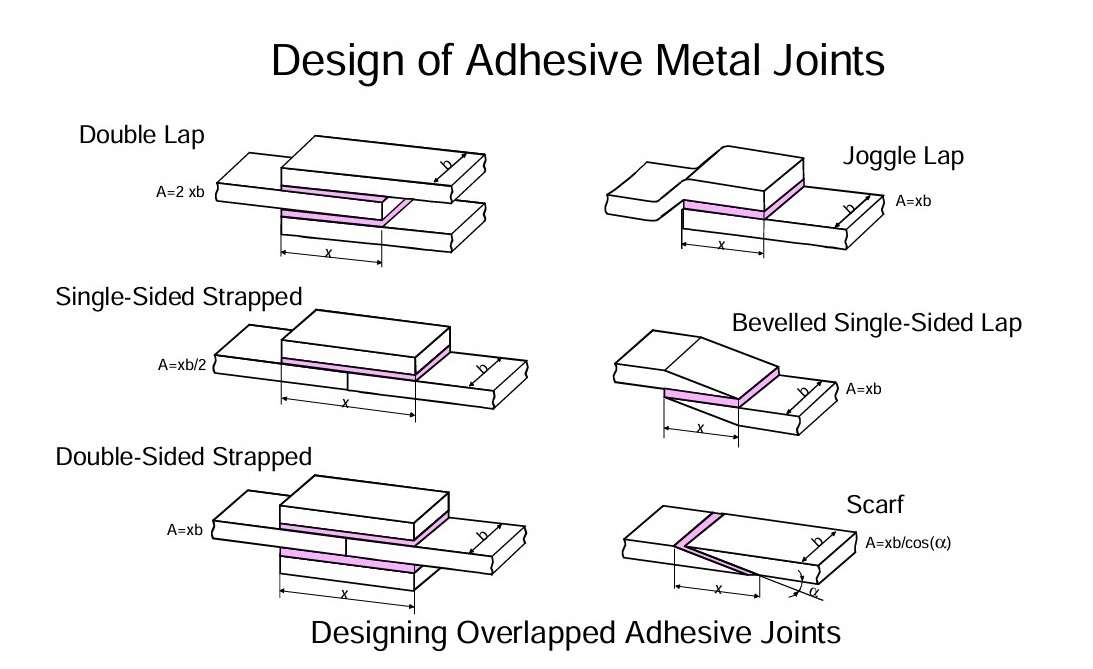

Figure 3 illustrates further possible designs for constructing overlapping adhesive joints. Scarf joints are most suitable for tensile-shear loading since the load distribution is favourable. These joints can, however, be used only for large joint part thicknesses and are complicated to manufacture.

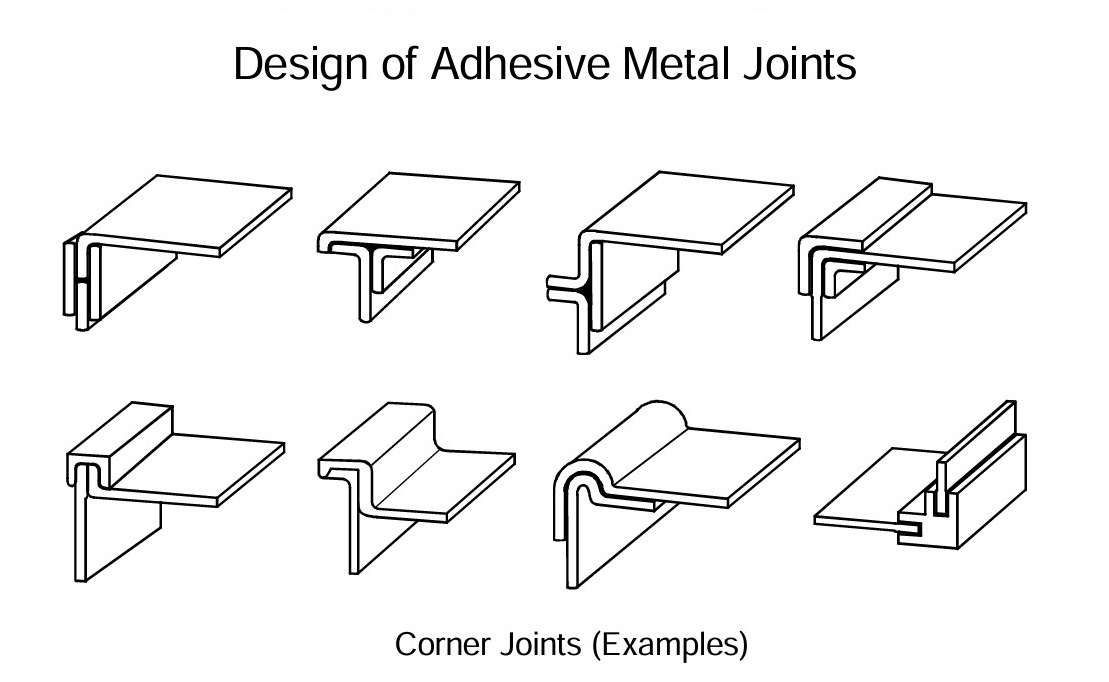

Examples for Joint Designs

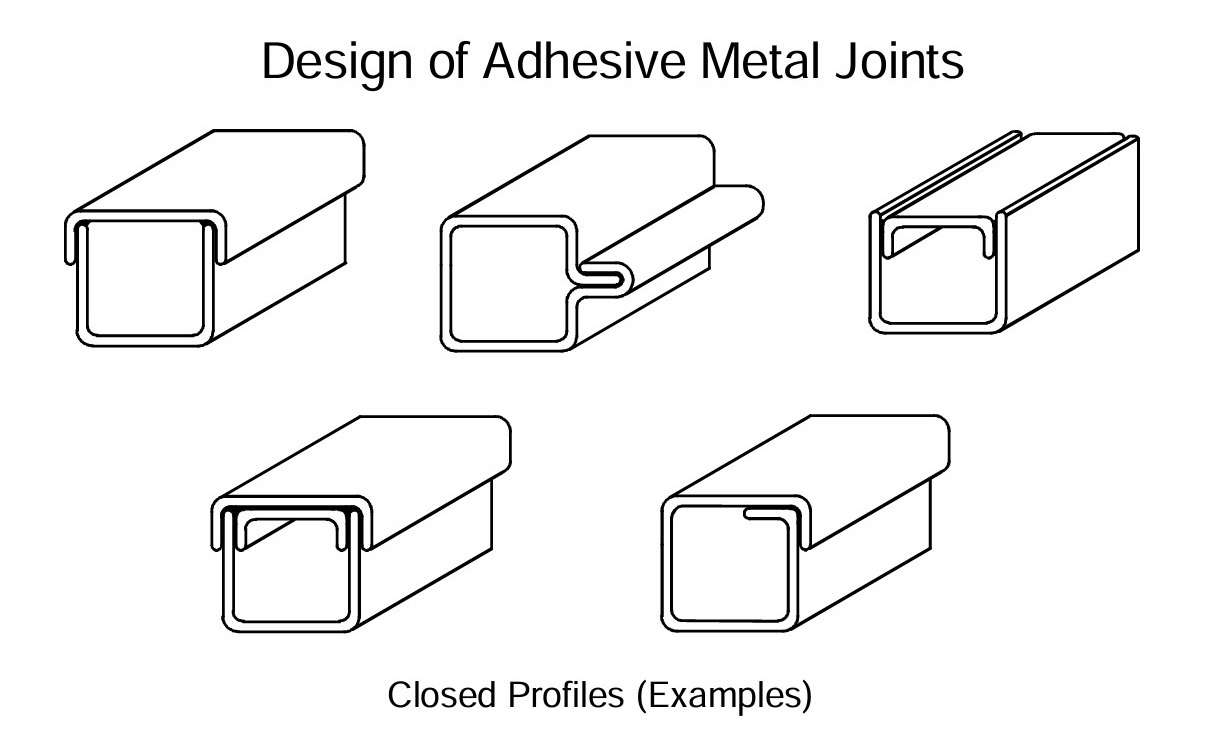

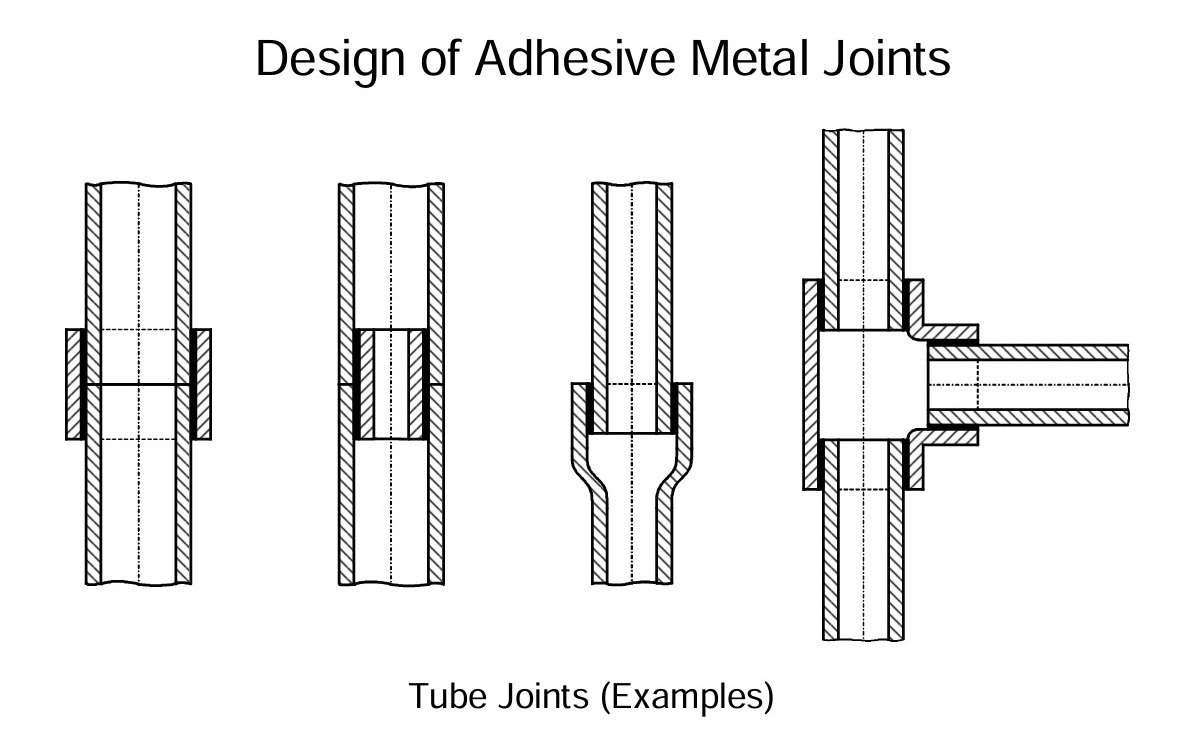

Designs which have proved most successful for corner joints, closed-sectioned profile joints and tube joints are illustrated in Figure 4, Figure 5 and Figure 6.

The examples of closed profiles

While joining tubes of different coefficients of thermal expansion adhesively, the tube with the larger expansion should be designed to be on the outside. Figure 6 – Tube joints

Figure 6 – Tube joints

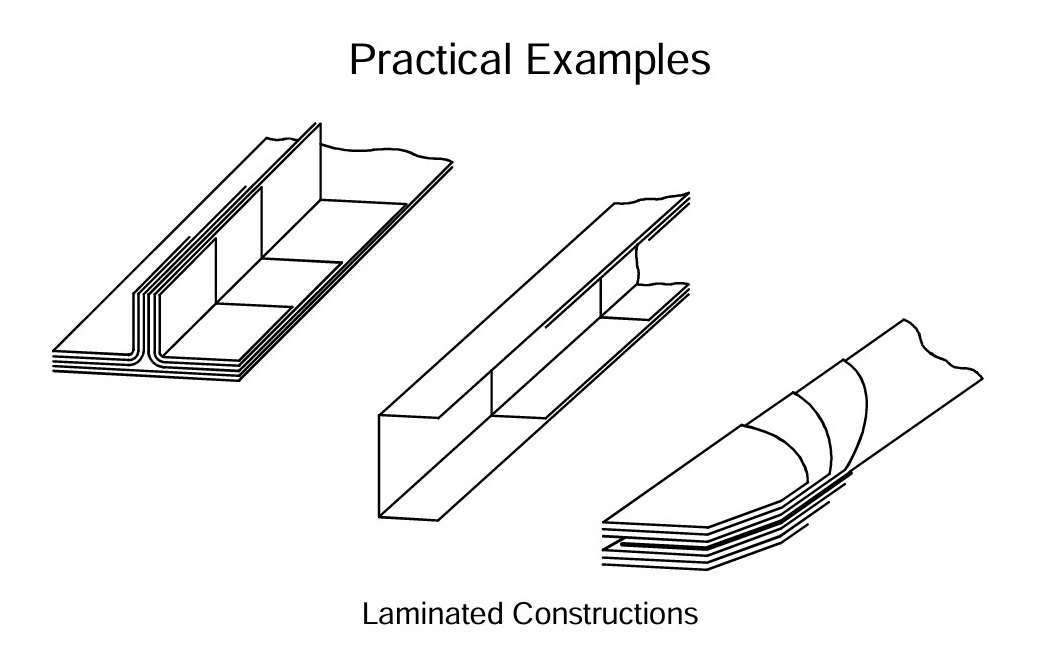

Layered or laminated joins

Typical application examples for adhesively joint metal constructions are layered or laminated, shell and sandwich constructions.

Figure 7 – Laminated constructions

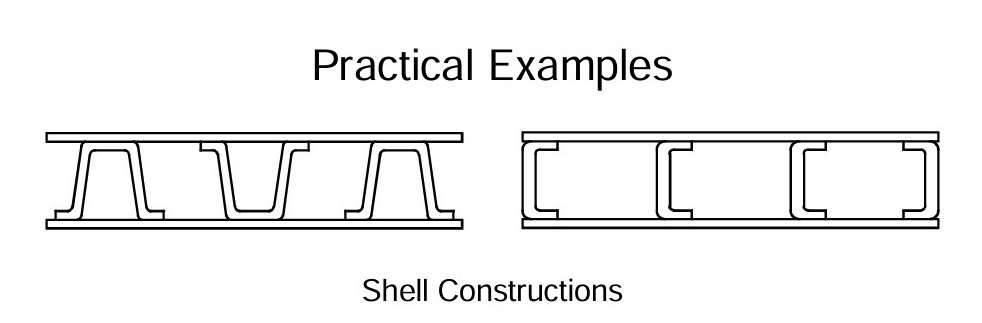

Figure 8 – Shell constructions

Figure 8 – Shell constructions

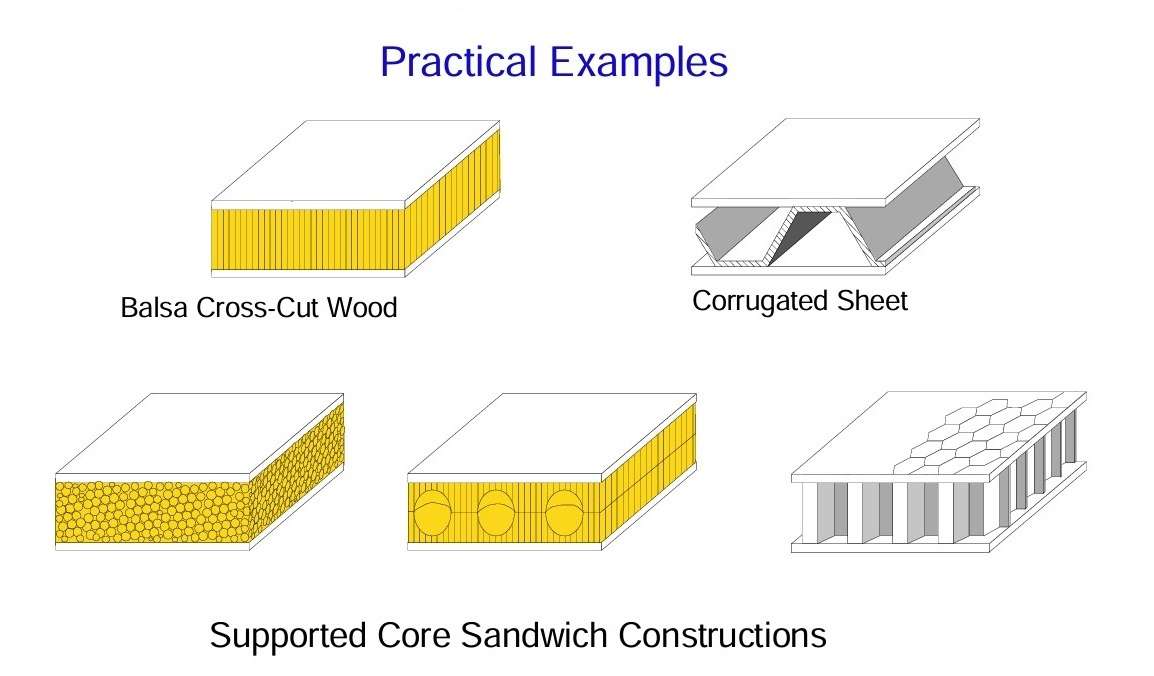

Supported Core Sandwich Constructions

Sandwich constructions are only possible with adhesive joining.

Figure 9 – Supported Core Sandwich Constructions

Figure 9 – Supported Core Sandwich Constructions

The source:

TALAT Lecture 4703 – Adhesive Joints – Design and Calculation / Lutz Dorn – European Aluminium Associatoins – 1994