A Classification of Aluminium Alloys

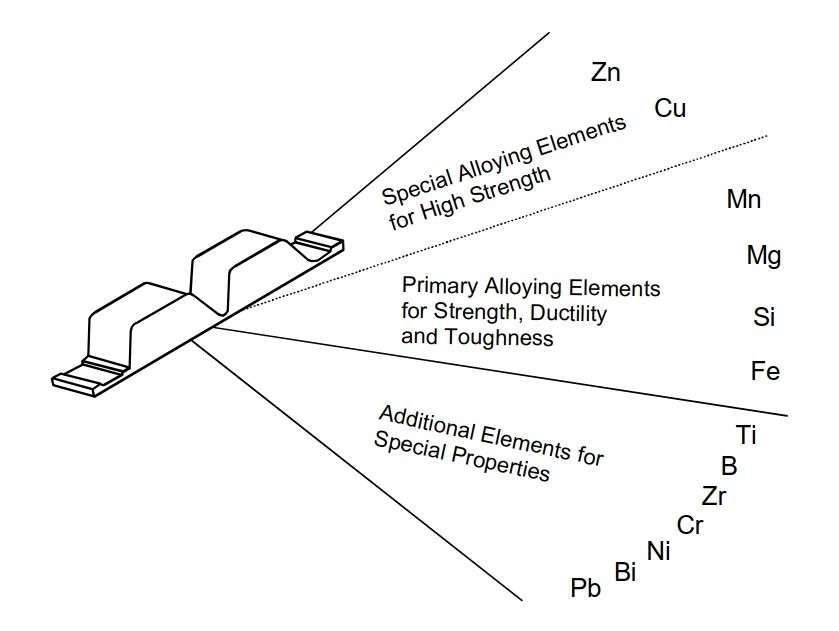

The most important alloying elements used to impart particular properties to aluminium are silicon (Si), magnesium (Mg), manganese (Mn), copper (Cu) and zinc (Zn). All commercial alloys contain roughly 0,1–0,4 per cent iron (Fe) by weight. The iron content may be viewed as an impurity in the metal. It depends on the raw materials (alumina) and the electrolytic reduction process. Iron is occasionally used to give the material special qualities (e.g. the properties of aluminium foil). Other alloying elements often used in combination with one or more of the major alloying elements include bismuth (Bi), boron (B), chromium (Cr), lead (Pb), nickel (Ni), titanium (Ti) and zirconium (Zr). These elements are usually used in small amounts (0,1 per cent by weight), although B, Pb and Cr may comprise up to 0.5 per cent) to tailor alloys for special purposes by imbuing them with properties such as castability, machinability, heat-resistance, corrosion-resistance, tensile strength, etc.

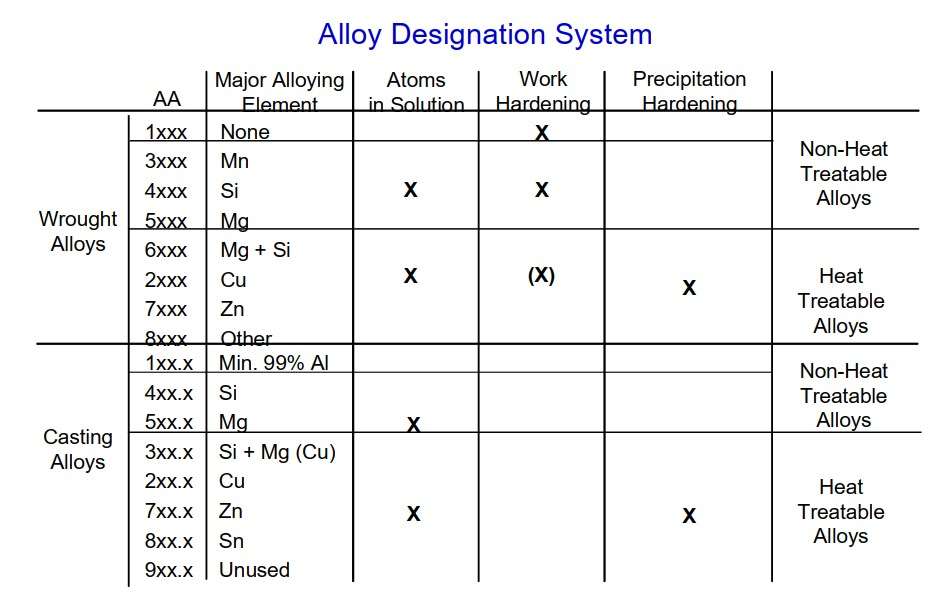

There are a number of different systems for classifying aluminium alloys. We will be using the standard set by the American Aluminum Association (AA), which is the most frequently used international standard. In some cases, we will use the ISO standard whose designations specify the content of the major alloying elements as percentages by weight.The European Norms (EN) is based on the two standards mentioned above.

Figure 1 presents the list of major alloying elements. The first digit in the designations classifies the alloys by major alloying element(s). A distinction is made between wrought alloys and cast alloys. The figure also specifies the mechanisms that contribute to the strength of the alloy class (atoms in solution, work hardening and precipitation hardening). A distinction is also made between non-heat treatable alloys and heat treatable alloys.The non-heat treatable alloys obtain their strength from the alloying elements in solid solution and different degrees of cold deformation and annealing.

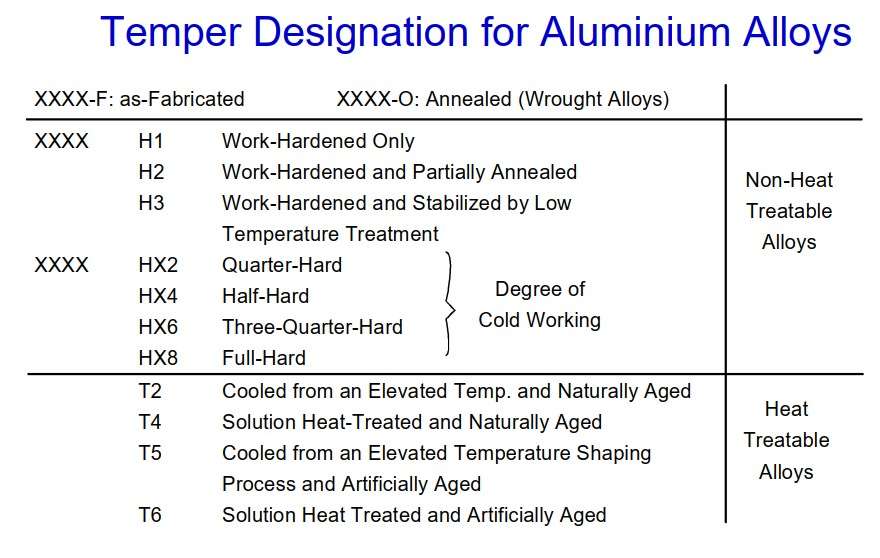

Figure 2 provides an overview of the standard combinations of work hardening and annealing. Heat-treatable alloys obtain their strength primarily from precipitation hardening.The figure also shows the designations of the standard solution heat-treatment and aging processes.

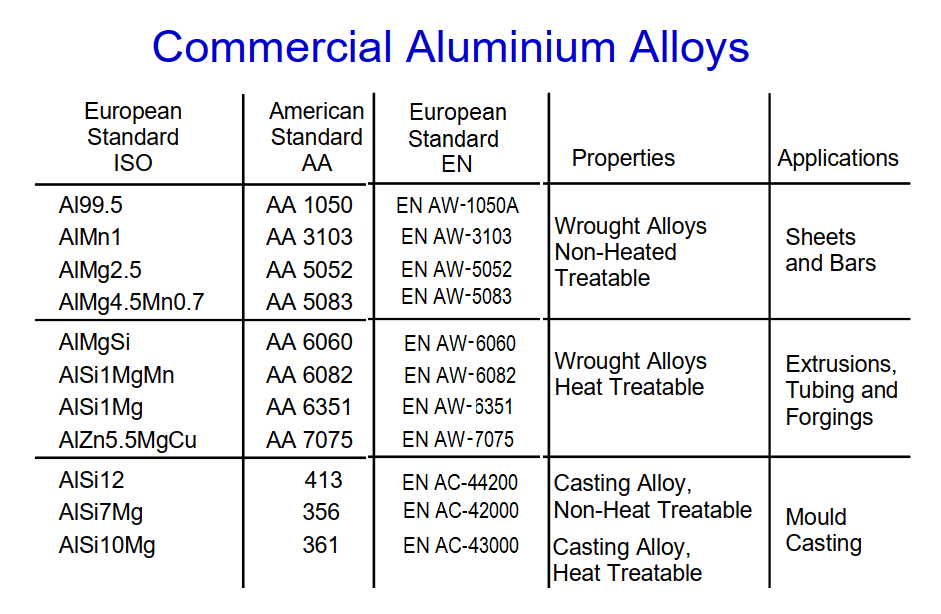

Figure 3 is a list of the most common commercial alloys available from all suppliers. These alloys have been used extensively and their properties are well documented.They may be referred to as “generic alloys” and it is always a good idea to take one of them as a point of departure during the concept phase of the product development process. If a special combination of properties is required, special alloys should be examined in consultation with a supplier. One of the generic alloys in the 7000 series, 7075, is especially strong. It is a socalled “aviation alloy”, primarily used in aircraft. However, high costs, reduced weldability and the risk of corrosion mean that these aviation alloys are rarely used in building construction or for marine applications or other types of transport.

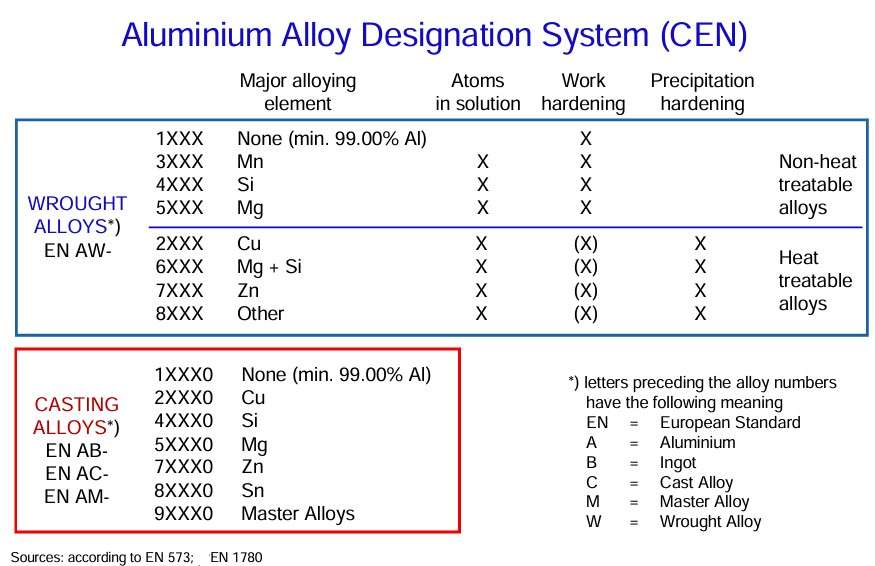

Figure 4 shows the European designation system for wrought and cast aluminium alloys.

The mechanical and other properties of an aluminum product depend not only on the chemical composition of the alloy it is made of. The technological history of this product, i.e. the technological operations, such as heat or deformation treatment, that it has undergone, is of great importance. These histories are called tempers, which have a special designation (Figure 5). The full material designation of an aluminum product usually contains four digits for the alloy designation and a combination of letters and numbers for the temper. For example, 6060-T6, where 6060 The full material designation of an aluminum product usually contains four digits for the alloy designation and a combination of letters and numbers for the temper. For example, 6060-T6, where 6060 designates the alloy and T6 the temper. the alloy and T6 The full material designation of an aluminum product usually contains four digits for the alloy designation and a combination of letters and numbers for the temper. For example, 6060-T6, where 6060 designates the alloy and T6 designates the temper.

Source: TALAT Lecture 1501 – Aluminium: Physical Properties, Characteristics and Alloys / Ron Cobden – European Aluminium Association – 1994