Brazing of aluminium

Brazing is a joining method which provides a permanent bond between the parts to be joined with the help of a brazing filler metal. The composition of the filler alloy is such that its melting point is slightly below the melting range of the parent metal of the parts.

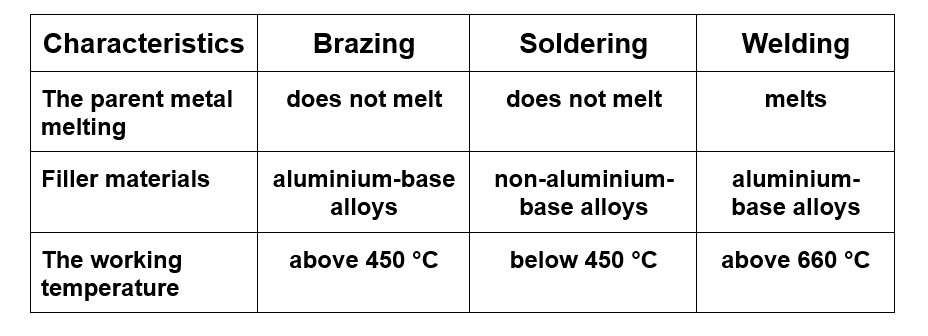

Brazing of aluminium is distinguished from welding of aluminium by the fact that the parent metal does not melt during the process. It differs from soldering by the facts that a) the brazing filler metal is an aluminium-base alloy and b) the working temperatures for soldering are appreciably lower. The working temperature for brazing is above 450 °C, whereas it is below 450 °C in the case of soldering.

The oxide surface of aluminium, although very thin, prevents the tight contact of the filler and parent metals. During brazing, therefore, the oxide has to be removed and, at the same time, the bare surface has to be protected against oxidation.

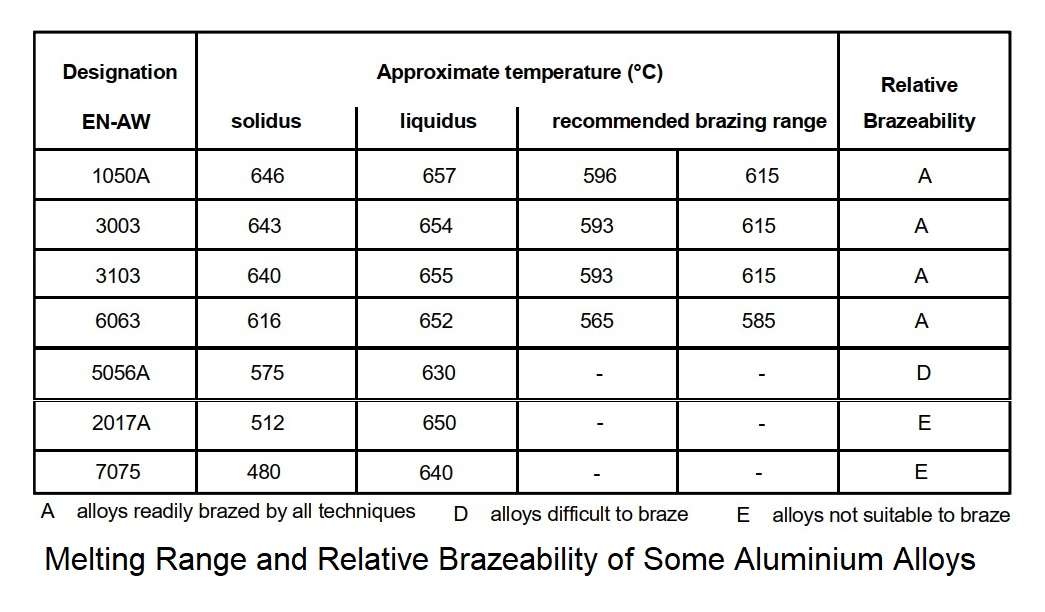

Generally, brazing of the various aluminium alloys is restricted by the available filler alloys which are based on the binary system Al – Si. Alloys of type 2XXX and 7XXX are, therefore, not brazeable as their solidus/liquidus temperature are too low for the filler metals.

Alloys with higher magnesium content (> 1 – 2 %) are difficult to braze due to increased oxide layer formation which cannot effectively be removed by fluxes.

Dependent on the source of heat the following most popular methods may be distinguished: torch brazing, flux-dip brazing and furnace brazing.

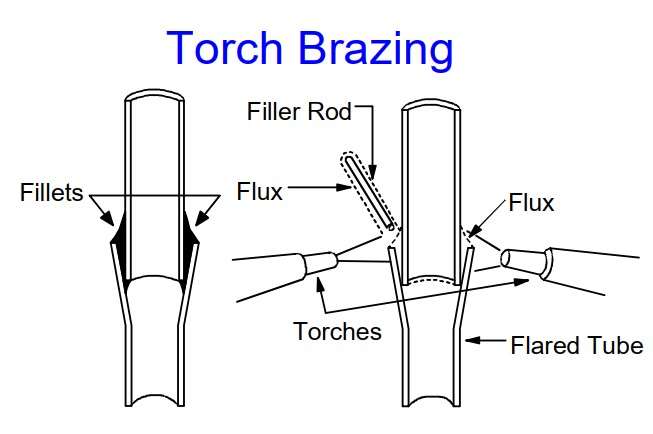

Torch brazing is typically being used for repair work, small production runs and as an alternative to fusion welding. It is accomplished with the same type of torch and gases used for welding. Aluminium brazing merely requires a change in torch nozzles and goggle lenses. All commercial gases can be used to fuel the torch.

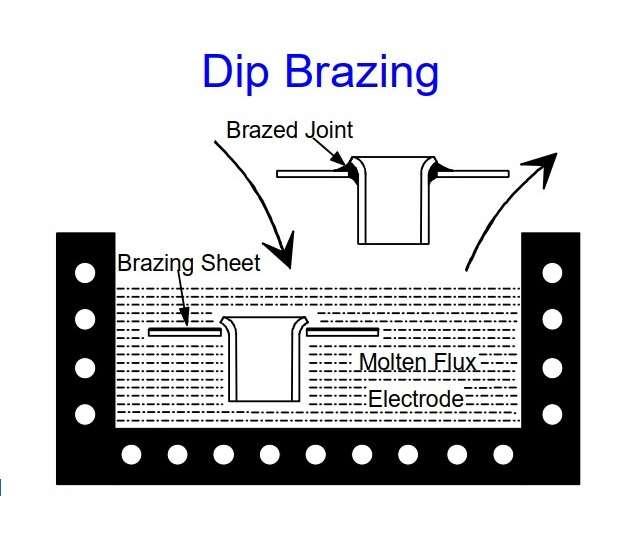

In Flux-Dip Brazing the parts to be brazed are cleaned, assembled and jigged together with the necessary filler metal. The assembly is pre-heated to approximately 540 °C, removed and immersed in molten flux (1 – 2 min.). In dip-brazing the temperature of the molten flux can be controlled within +/- 3 K. This will allow the use of filler metals with liquidus temperatures as close as 6 K to the solidus temperature of the base metal.

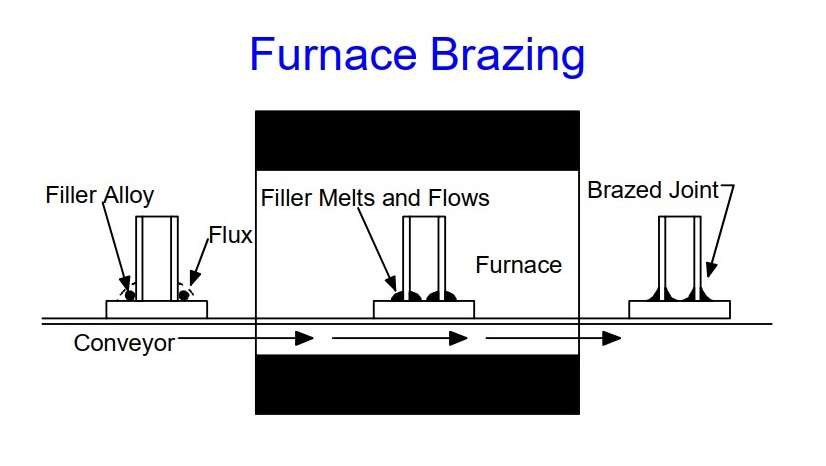

Furnace brazing is the most popular method of brazing aluminium alloys. The working surfaces are fluxed, the filler metal positioned and the parts are assembled and jigged. It is required to control the furnace temperature within +/- 3 K. After brazing the assembly shall be cooled or quenched if possible.

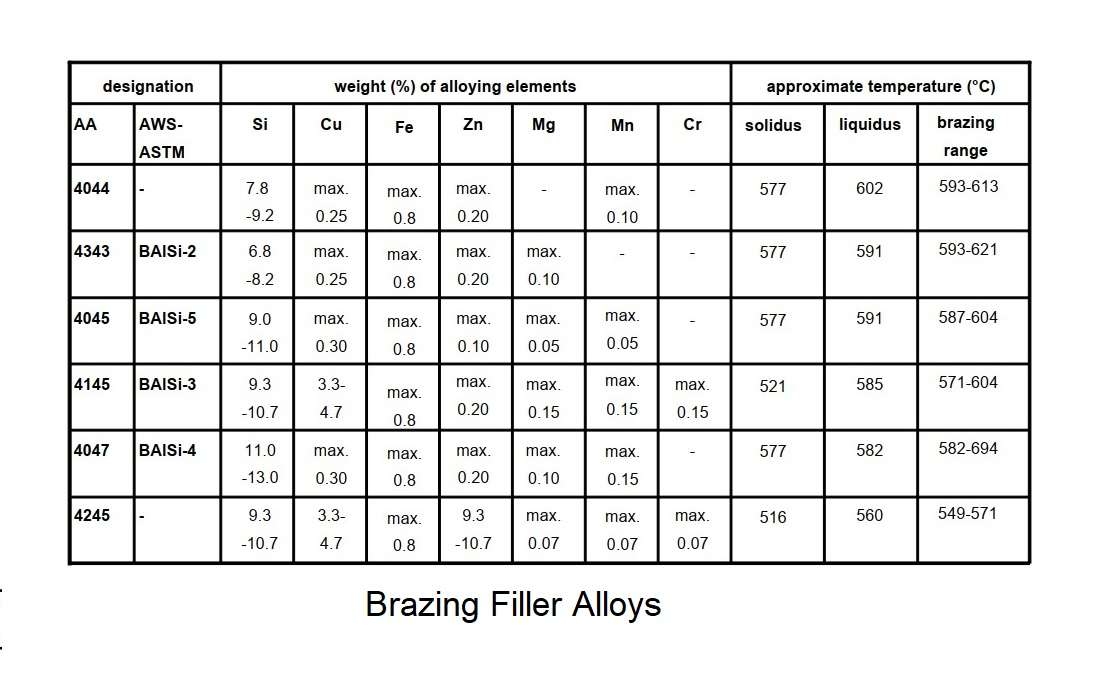

The standard commercial filler metals are based on the aluminium-silicon-system containing 7 to 14 % silicon. Increasing silicon content decreases the liquidus temperature, solidus is equivalent to the eutectic temperature. Additions of copper and zinc act to lower both solidus and liquidus temperatures still further. Furthermore, sometimes elements like magnesium, zinc or bismuth are added to improve the brazeability. The elements added and their concentration are dependent on the individual brazing process.

The fluxes perform a number of important functions simultaneously during the brazing process: displacement of the oxide layer, protection of the bare metal surface, lowering the surface tension of the filler metal, promotion of wetting characteristics and filler fluidity. Aluminium brazing fluxes contain primarily alkali and alkaline chlorides and fluorides, occasionally aluminium fluoride or cryolite.

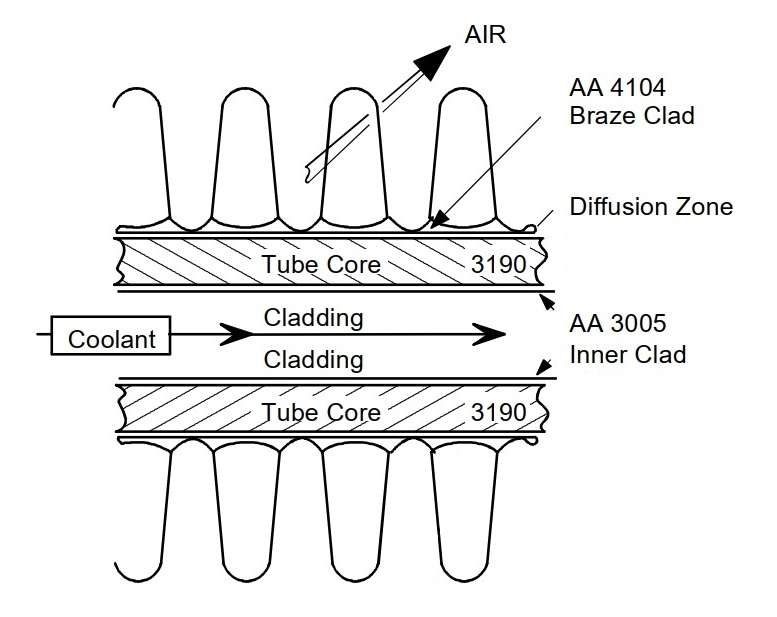

Good example of aluminium brazing is brazed aluminium heat exchangers in radiators, oil coolers, heating and air conditioning equipment for all types of vehicles. Typical core material for separator sheets, extruded sections and fins is AA 3003.

Sources:

- TALAT Lecture 4601 – Introduction to Brazing of Aluminium Alloys / R. Mundt – European Aluminium Association – 1994

- Aluminum and Aluminum Alloys, ASM International, 1996

- Brazing of Aluminum Alloys / Y. Sugiyama // Encyclopedia of Aluminum and Its Alloys – Eds. G.E. Totten, M. Tiryakioğlu, and O. Kessler – 2019 – 171-182

- Brazing/Joining / Aluminium Automotive Manual – European Aluminium Association – 2015