Blind Rivets for Aluminium Structures

Well designed joints are essential to ensure the satisfactory performances of any aluminium structure. When components have to be riveted together in situations where the rivet is not accessible from both sides, blind riveting systems provide a solution to the problem. Using a suitable tool the rivets are inserted from one side and a closing head is formed.

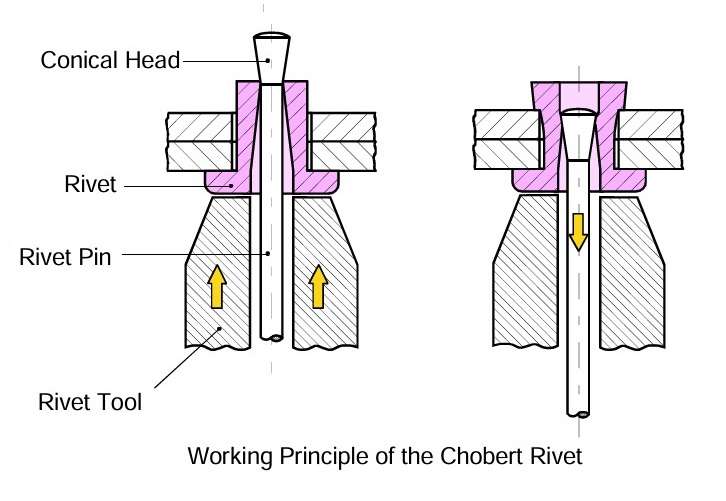

Chobert Blind Rivet

One type of hollow-shanked rivet, known as the Chobert rivet, is made from steel or aluminium alloys. The figure shows a conical rivet hole tapering from die head side to the shank end. The closing head is formed by gathering up the material at the end of the rivet shank. In sealed joints, or to increase the shear strength, the hollow shank can be closed by a filler pin. A rivet with its filler pin in place can be regarded as almost equivalent to a solid rivet. The aluminium rivets are made of AlMg5; the filler pins, of AlCuMg , cadmium-plated steel, or plastics.

Figure 1 – Working principle of the Chobert rivet

Figure 1 – Working principle of the Chobert rivet

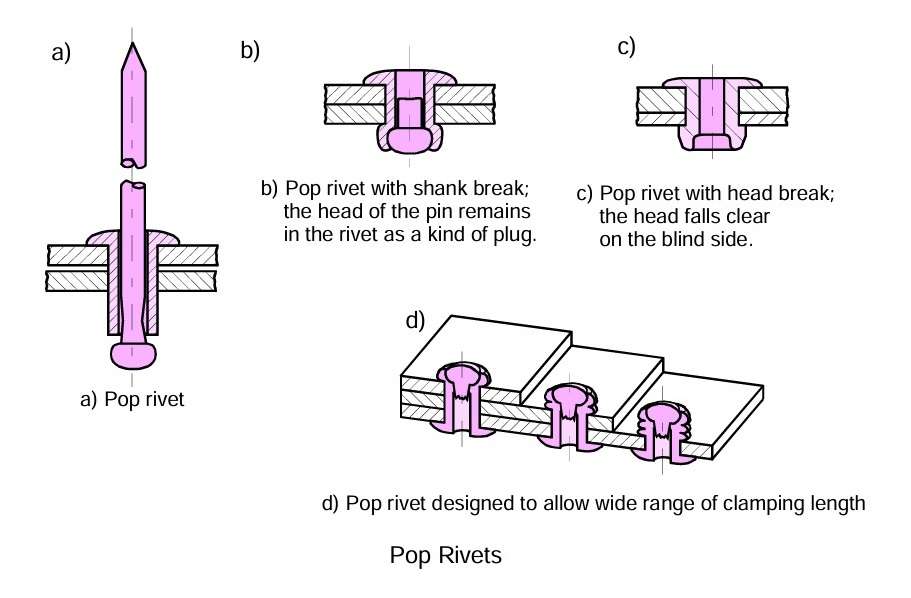

Pop rivets

Pop rivets consist of a riveting pin and a rivet sleeve with a flat or countersunk head. In the riveting process the tool first pulls the sheets tightly together and then forms the closing head. Finally, the pin breaks off at a predetermined point. In some types the pin breaks at a point within the rivet shank, and its head then remains as a sort of sealing plug. In other types the head breaks off and falls clear on the blind side. In this case, too, the hollow shank can be closed off by a metal or plastic filler pin, or by an aluminium cap.

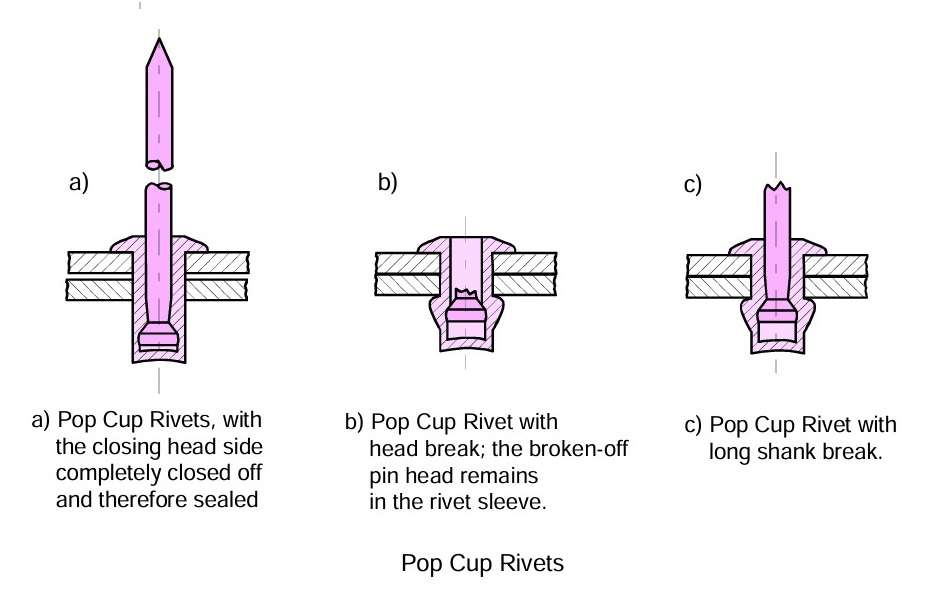

Cup rivets

Cup Rivets are blind rivets and a variant of the pop rivet. The riveting procedure and the tool are just the same, but the closing head side of the rivet is completely closed and thus perfectly sealed. The broken off head of the pin remains in the rivet sleeve. Cup rivets are available in “head break” or in “shank break” versions.

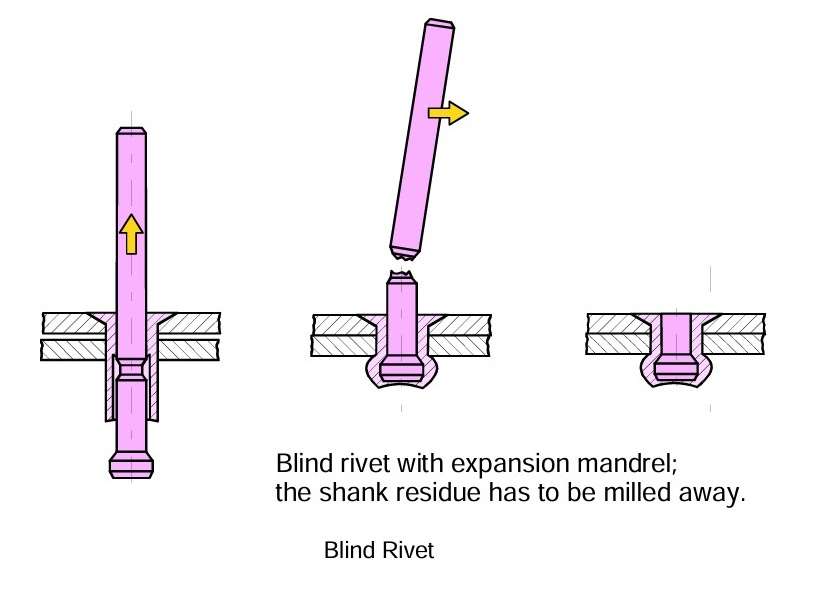

Blind Rivets with Expander Mandrels

The Figure shows a type of rivet with a mandrel which, when pulled through, first expands the rivet sleeve and then forms the closing head. The fracture point of the mandrel is so chosen that the part left behind projects far out of the rivet sleeve, and must be milled flush to the surface.

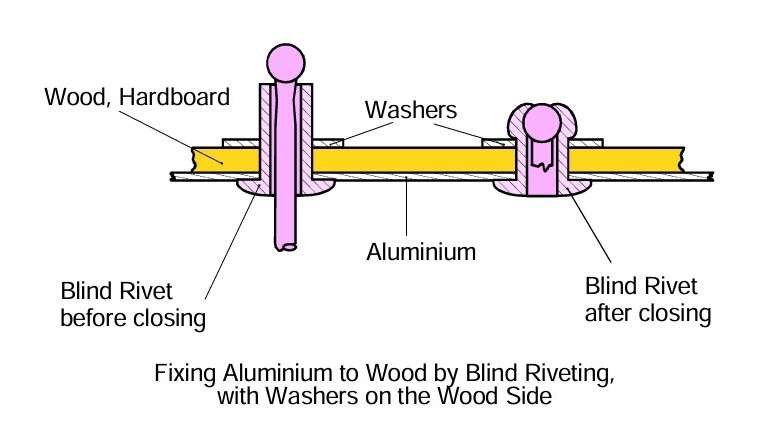

Riveting of Aluminium Sheet to Soft Material

In practice, soft materials (wood, cardboard, hardboard) are often clad with aluminium sheet. A rapid and durable joint can be formed by passing a washer of the corresponding size over the shank of the blind rivet and closing the rivet over this.

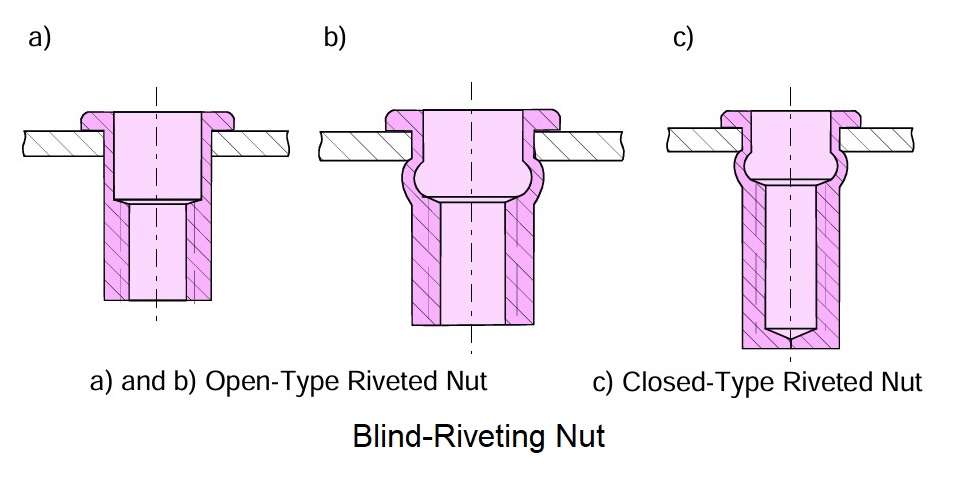

Blind-Riveted Nuts and Screw Rivets

There are two versions: the open type and the closed type. Other products are a blind-riveted nut, a two-sided riveted nut, a hammer nut, and a screw rivet. Apart from these, there are different types of driven fasteners.

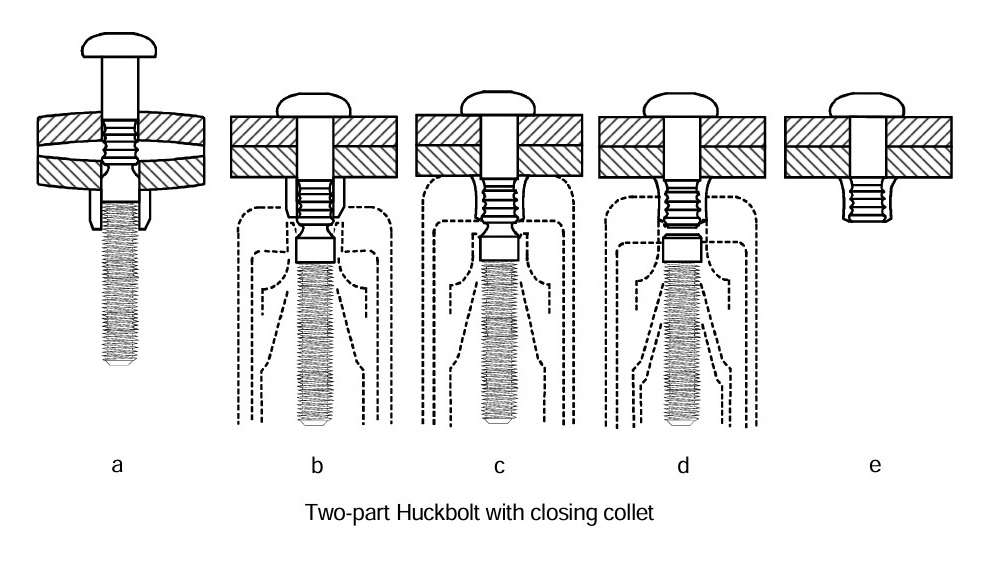

Huckbolts

Huckbolts are not blind rivets in the strict sense of the term, since the bolts are introduced from the rear, while the closing operation is performed on the working side. The particular advantage of this method is that the rivet bolt itself is not deformed. The bolts are made of steel or aluminium (AlMg5). The joint can withstand very high shear and tensile stresses.

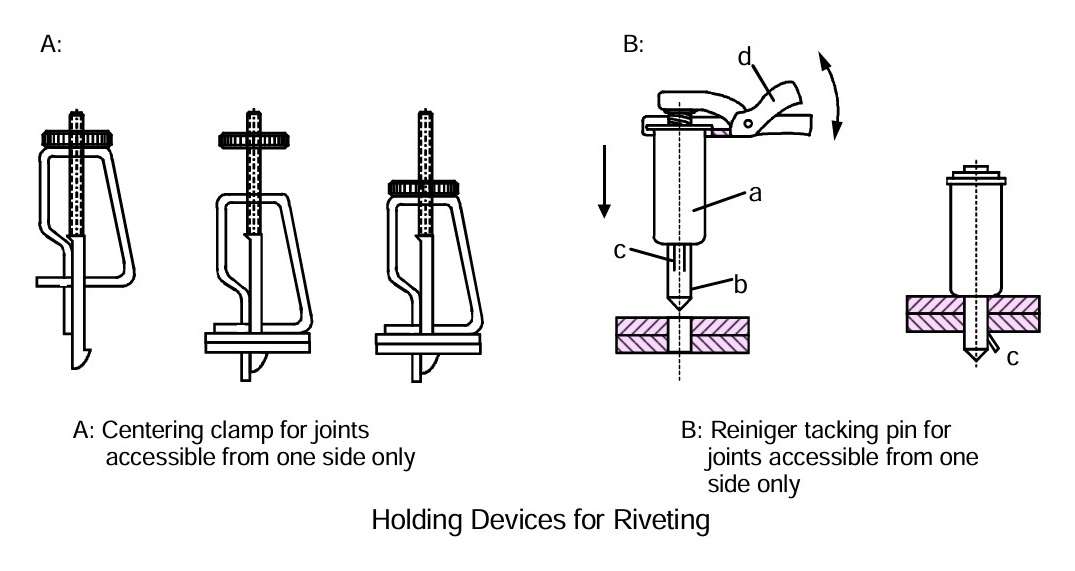

Holding Devices for Riveting

Riveted joints can be made more easily with the aid of suitable holding devices. These can be obtained from the manufacturers of blind rivets. Moreover, there are other, virtually essential aids such as centering clamps, tacking pins or tacking screws. It should, however, be mentioned that such aids are mostly intended for use with lighter sheetwork (holes up to about 6 mm diameter).

The source:

TALAT Lecture 2302 – Design of Joints / T. Höglund – 1994. Updated according to EC9 by Federico M. Mazzolani – European Aluminium Association – 1998.