Atmospheric Corrosion of Aluminium

Explore the book ‘Corrosion of Aluminium’ by Christian Vargel and learn about the resistance of aluminium to atmospheric corrosion.

The contents of the book on atmospheric corrosion of aluminium

The Resistance of Aluminium to Atmospheric Corrosion

- The Dome of San Gioacchino Church, a 100-year-old Experience

- Atmospheric Corrosion of Aluminium Over Time

- Weathering Resistance of Wrought Alloys

- Weathering of Casting Alloys

- Weathering Resistance of Anodised Semi-products

- The Nature of the Alloy

- Anodising Conditions

- Film Thickness

- Maintenance

- References

From the book “Corrosion of Aluminium” by Christian Vargel.

The nature of atmospheric corrosion of aluminium

Atmospheric corrosion is the attack of a metal (or an alloy) by the atmospheric environment to which it is exposed. This corrosion is caused by the simultaneous attack by

- rainwater or condensing water,

- oxygen contained in the air, and

- atmospheric pollutants.

The parameters of atmospheric corrosion

The factors of atmospheric corrosion

The resistance to atmospheric corrosion of a metal, includung atmospheric corrosion of aluminium, depends on several factors:

- Relative Humidity

- Rain

- Fog

- Condensation

- Temperature

- Gaseous Pollutants

- Sulphur Dioxide (SO2)

- Carbon Dioxide (CO2)

- Hydrogen Sulphide (H2S)

- Ammonia (NH3)

- Nitrogen Oxides (NOx)

- Volatile Organic Compounds

- Chlorine (Cl2)

- Chlorides (Cl–)

- Dust

- Alternating Periods of Dampness and Dryness

The forms of atmospheric corrosion

The most frequent forms of atmospheric corrosion of aluminium are

- pitting corrosion,

- galvanic corrosion, and

- filiform corrosion of coated products.

Uniform corrosion is not observed because it is so minute that it cannot be measured. Other forms of corrosion of aluminium and its alloys such as exfoliation corrosion, stress corrosion, etc. are possible on age-hardenable alloys of the 2000 and 7000 series. However, the selection of alloys and their protection, if present, normally prevents these forms of corrosion from occurring in outdoor applications such as buildings or bridge railings.

The excellent resistance to weathering of aluminium alloys of the 1000, 3000, 5000, and 6000 series without copper can be attributed to the properties of the natural oxide film. The corrosion products are insoluble in slightly acidic or almost neutral media and tend to slow pitting corrosion once it has initiated. This explains the self-limiting effect of the atmospheric corrosion of aluminium, which has been observed for more than 50 years.

The curves in Figure 1 represents the progression of pitting depth (maximum and mean values). These are the results of real applications and corrosion tests obtained in outdoor testing stations. The duration of service or testing ranges from 5 to 54 years.

Three stages in atmospheric corrosion

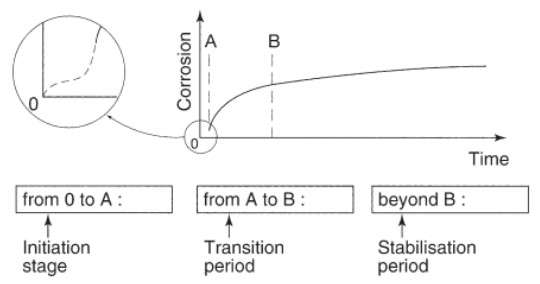

The general shape of these curves representing results over long periods of time is always the same, whatever the type of atmosphere: rural, industrial or marine. Three stages can be distinguished in atmospheric corrosion of aluminium (Figure 2):

- An initiation stage, during which pitting corrosion starts at fragile sites of the natural oxide film.

- A transition period, which may last for several months or even years.

- A stabilisation period, during which the deepening rate of pits is very low.

If corrosion is in progress, the density of pitting increases with exposure time.

Figure 1 – Atmospheric corrosion of aluminium [1]

Figure 1 – Atmospheric corrosion of aluminium [1]

Figure 2 – The stages of atmospheric corrosion of aluminium [1]

Figure 2 – The stages of atmospheric corrosion of aluminium [1]

Weathering resistance of aluminium alloys

Wrought alloys

- The copper-containing alloys of 2000, 6000, and 7000 series are not intended for exposure to weathering and atmospheric corrosion without adequate protection such as specific anodising, cladding, etc.

- Also, they are sensitive to intercrystalline corrosion, exfoliation corrosion, and stress corrosion, and even more so in the T4 temper than in the T6 temper.

Casting alloys

It has been known that silicon- and magnesium-containing casting alloys have a high resistance to atmospheric corrosion. The testing results over 10 years in an industrial atmosphere showed that the pitting depth of samples does not exceed 175-200 micrometers.

- In general, casting alloys without copper show an high resistance to atmospheric corrosion. They are widely used in construction and shipbuilding, electrical engineering, etc.

- The use of copper-containing alloys should be avoided. From experience, it is known that severe corrosion can occur in urban and industrial atmospheres.

Source:

1. Corrosion of aluminium /Christian Vargel – Elsevier – 2004