Aluminium extrusion pullers

The crucial role of an aluminium extrusion puller in the extrusion process. Discover how it maintains profiles, signals the press, provides tension, and enables accurate cutting of profiles.

An aluminium extrusion puller

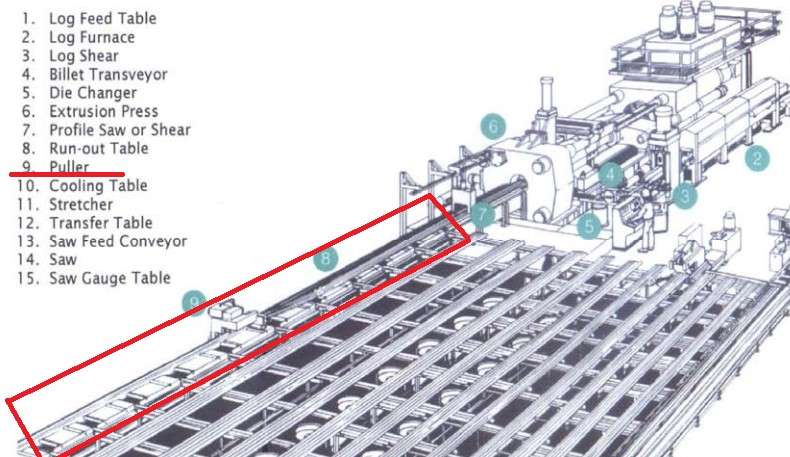

An aluminium extrusion puller is a pulling device, which directs extrudate along the run-out table (Figure1).

Figure 1 – An extrusion aluminium puller in typical extrusion press handling system [1]

Functions of the extrusion puller

The puller of extrusion press should perform, how miniumum, the following four functions [1]:

- Adopt and maintain profiles on the receiving table for the entire length of the roller output in each cycle press unattended

- Give a signal to the press to stop pressing, is achieved when the predetermined length of the profile

- To provide a tensile force in accuracy sufficient for, all profiles mnogoochkovoy matrix were identical length

- Promote hot cut saw cutting profile exactly in the space on the outlet roller conveyor, where they will be sent further to the cooling table.

To be able to perform these functions, the puller must be:

- reliable – have a probability of failure of not lower than, than other parts of the press line;

- fast – to perform their tasks and return to the starting position during the technological pause of the press;

- smooth – operate without damage profiles.

Pullers types

Various pullers may differ from each other as intended, and a separate design specifications.

Single puller

Most of the early pollers were single. However, understandably, that a single puller difficult to keep coming back to the starting position on the output table during the waiting time of the press when changing workpiece. The duration of the pause is usually not more than 20 seconds, and the output length of the table, which is necessary to have time to pass Puller, often it is about 50 m. It should be noted, that at an excessively large rate of movement of the puller decreases its reliable operation.

Double puller

To reduce the non-productive downtime media have been developed various types of double pollers, that provide the, that at the beginning of each pressing cycle one of the pullers is always in the starting position near the press:

- two puller, front and rear, the first transfers the profile to the second during the pressing cycle;

- Parallel Pullers (Twin Pullers), who work in the press cycle turns, that is, through a cycle;

- The combination of the main and auxiliary puller puller. The main puller pulls the profile during the press cycle, and the auxiliary puller drove the profiles already cut more by the output roller conveyor for transfer to a cooling table.

- A combination of a saw-puller and conventional puller. Puller-saw cuts the profile of the track welding and helps ordinary puller spending profile for the output table.

Location puller

Pullers are moving along the guide rails, which can be placed directly on the output table or next to it.

Drive puller

The following types of puller drives are commonly used:

- cable,

- chain,

- a linear motor and

- rack.

The supply of electric power to the puller

The energy to drive the puller arms (and the hot-cut saw, when it is installed on one of the pullers) can be supplied:

- on cable suspension,

- on the supply rails or

- in the form of compressed air to the air cylinders, are charged after each working cycle.

Types of seizures and their actuators

Puller grips can be in the form of a vise or consist of several segments (fingers). The grippers are opened and closed by pneumatic cylinder, springs, hydraulic cylinders or linear electric actuators.

Sources:

- Extrusion Press Maintenance Manual / Al Kennedy

- Jürgen Sturm and Jaume Amoros, Servo-Drive Applications in Aluminum Profile Extrusion Equipment, Aluminium ET Seminar, Chicago, 2016