Aircraft aluminium: rolled, extruded and forged

Aluminium is the material of choice for most aircraft structures.

High-strength aluminium alloy is the most used material for the fuselage, wing and supporting structures of many commercial airliners and military aircraft.

Figure 1

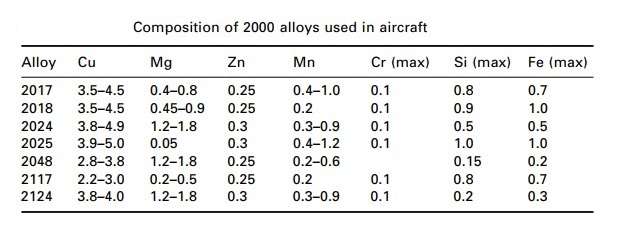

Aluminium accounts for 70–80% of the structural weight of most airliners and over 50% of many military aircraft and helicopters. In recent years, however, the percentage of airframe weight consisting of aluminium has declined owing to greater use of carbon fibre–polymer composites.

Figure. 2 – Materials selection for structural members of a typical passenger aircraft

Aluminium is not used in their as-cast condition for safety-critical aircraft structures or load-bearing jet engine components. Cast metals are used in a small number of nonstructural components on aircraft and helicopters, but not in heavily loaded structures which require high strength and toughness. The mechanical properties of cast metals are not good enough for them to be used in aircraft structures without incurring a significant weight penalty. Instead, aluminium alloys are processed after casting by plastic-forming operations which increase the strength properties. Materials processed in this way are called wrought metals.

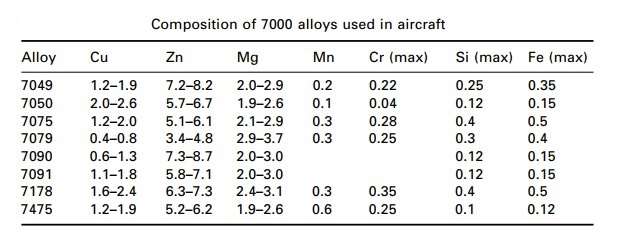

The 2000 alloys are used in many structural and semistructural components in aircraft. The main alloying element is copper, which readily forms highstrength precipitates when aluminium is age-hardened by heat treatment. 2000 alloys are characterised by high strength, fatigue resistance and toughness. These properties make the alloys well suited for fuselage skins, lower wing panels and control surfaces.

The 7000 alloys together with the 2000 alloys represent by far the most common aluminium alloys used in aircraft. The main alloying elements in 7000 alloys are copper and zinc, with the zinc content being three to four times higher than the copper. Magnesium is also an important alloying element.

Figure 4

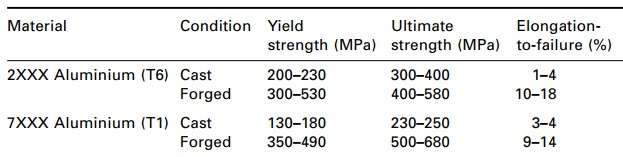

Most forming processes are designed to simultaneously harden and deform the metal into a simple shape, such as a sheet, plate or bar, which is then heat-treated and machined into the final component. The plastic forming of wrought metal increases the mechanical properties by the strengthening mechanisms of work hardening, grain refinement, elimination of casting defects (such as porosity), and the breakdown of alloy segregation in the casting. The yield strength of a wrought aluminium alloys is typically 50–200% higher than the cast metal with the same alloy composition.

Wrought aluminium used in aircraft structures are produced using various processes, with the most common being forging, extrusion, rolling and sheet forming. Other processes used by the aerospace industry are superplastic forming and hot isostatic pressing.

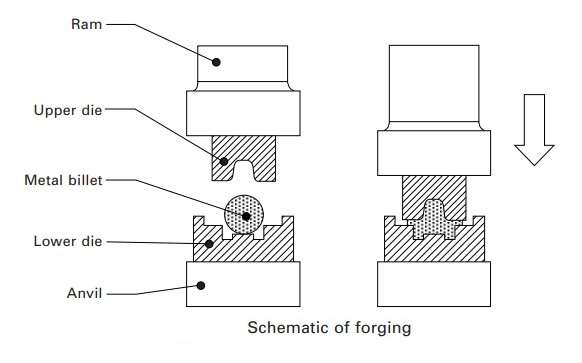

Forging is a forming process used to strengthen and shape thick sections of cast metal. The process involves plastically deforming the metal under high compressive forces inside a die cavity. Deformation usually occurs by repeated strokes or blows applied using hammers, mechanical presses or hydraulic presses.

Forging is performed at room temperature, called cold working, or at elevated temperature to make the metal soft and ductile, called hot working. Most aerospace metals are hot forged; for example the 2000 aluminium alloys are forged at 425–460 °C whereas the 7000 alloys are forged at 400–440 °C.

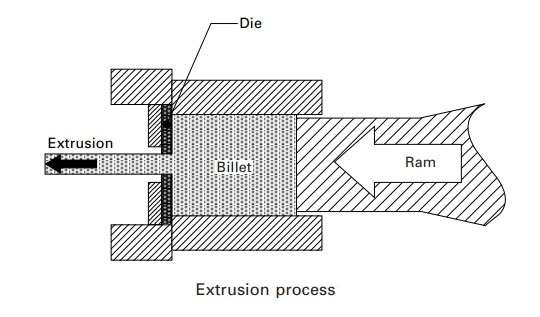

The forming process of extrusion involves pushing metal through a die under high compressive force. The cast metal (called a billet), which is hot or cold, is placed inside the die cavity and then squeezed through an annular opening in the die under force applied by a hydraulic ram. The metal effectively squirts out as a continuous bar having the same cross-sectional shape as the die opening. Extrusion is used to produce components of uniform cross-section such as beams and rods. Extruded ‘T’, ‘H’ ‘J’ and ‘L’ shaped sections are used for wing stringers and fuselage frames. High strength aerospace alloys, including 2000 and 7000 aluminium alloys, are referred to as ‘hard’ alloys because they are difficult to extrude.

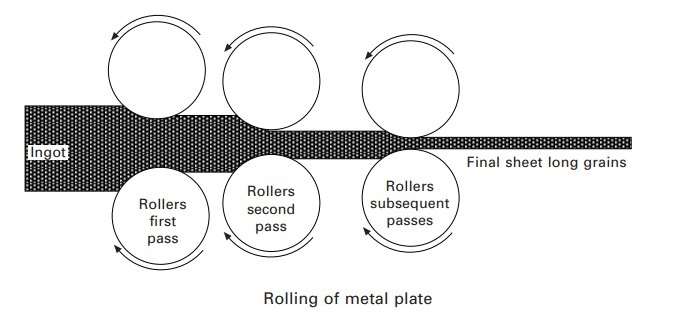

Rolling is a process that plastically deforms thick metal under heavy rollers into thin sheet. Rolling is used to produce high-strength sheet metal for skin panels, stringers, frames and other thin-walled structures in aircraft. The rolling process usually begins with hot rolling of the ingot to close any pores and break down the coarse grain structure of the casting. The thickness of the ingot is reduced progressively by a series of rolling operations. Rolled products are classified as either sheet (with a thickness between 0.15 and 6 mm) or plate (thickness greater than 6 mm).

Widths can range up to about 2500 mm. Rolled aluminium sheet and plate in the range of about 1 to 10 mm is used in the fuselage skin and stringers. Thicker plate (25 to 50 mm) is used for wing skins, and the thickest plate, up to 200 mm, is used for bulkheads, wing spars and supporting structures.

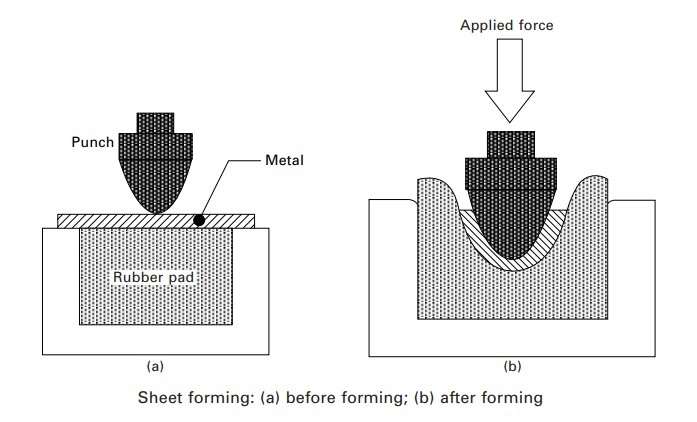

Sheet forming is used to produce curved panels for large structures such as the fuselage. The process involves clamping the ends of rolled metal sheet (usually thinner than 6 mm) and then stretching over a forming block to the desired shape. The pressure used to stretch the sheet is applied through male or female dies or both. The sheet is pressed into the rubber pad under force applied through the punch. The flat sheet is plastically deformed into the punch shape without any major change in the sheet thickness.

The sources:

- Introduction to Aerospace Materials / Adrian P. Mouritz – 2012

- Encyclopedia of Aluminum and Its Alloys / Eds. G. Totten, M. Tiryakioğlu, O. Kessler – 2019