Aluminium sand casting

Learn about the properties and benefits of aluminium casting in sand moulds. Find out how this versatile process produces high-quality castings in various shapes and sizes.

Aluminium sand casting

Sand casting, including aluminium sand casting, involves the forming of a geometrically dimensioned impression in sand.

A sand mold

The important parameters of molding sand are compressive strength and permeability. Tests for each are routinely performedfor quality assurance. The mold must have sufficient strength to maintain its shape through the casting process and sufficient permeability to permit the air, and gases formed during pouring, to evacuate the mold cavity as the metal enters. Compressive trength

and permeability are functions of sand particle size and shape, moisture and binder contents, and the degree of compaction applied in forming the mold.

The advantages of sand casting

The advantages of typical sand casting are versatility in a wide variety of alloys, shapes, and sizes. Alloys considered hot short because of cracking tendencies during solidification are more easily cast in green sand since molds offer reduced resistance to dimensional contraction during solidification. Lower mold strength is also advantageous for parts with widely varying section thicknesses and intricate designs. These advantages are diminished in chemically bonded molds, which display greater rigidity than green sand molds.

Sizes and tolerances

- Typical minimum wall thickness is normally 4 mm, but thicknesses as little as 2 mm can be achieved.

- Dimensional accuracy are relatively low. Basic linear tolerances of 30 mm/m with a minimum tolerance of 20 mm/m.

- Achievable dimensional tolerances can be substantially improved using precision methods in the forming and assembly of dry sand mold components.

- Surface quality can be improved by using a finer grade of facing sand in the molding process.

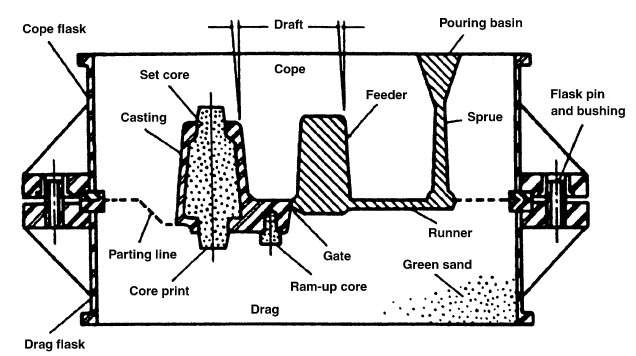

Figure 1 – Typical sand mold gating [1].

Figure 1 – Typical sand mold gating [1].

The process cycle for sand casting

The process cycle for sand casting, including aluminium sand casting, consists of six main stages [2].

Sand mold making

The first step in the sand casting process is to create the mold for the casting:

- A sand mold is formed by packing sand into each half of the mold.

- The sand is packed around the pattern, which is a replica of the external shape of the casting.

- When the pattern is removed, the cavity that will form the casting remains.

- Any internal features of the casting that cannot be formed by the pattern are formed by separate cores which are made of sand prior to the formation of the mold.

Clamping

- The surface of the mold cavity is first lubricated to facilitate the removal of the casting.

- The cores are positioned and the mold halves are closed and securely clamped together.

Pouring

- The molten metal is maintained at a set temperature in a furnace.

- The molten metal can be ladled from its holding container in the furnace and poured into the mold.

- Enough molten metal must be poured to fill the entire cavity and all channels in the mold.

- The filling time is very short in order to prevent early solidification of any one part of the metal [1].

Cooling

- When the entire cavity is filled and the molten metal solidifies, the final shape of the casting is formed.

- The mold can not be opened until the cooling time has elapsed.

- The desired cooling time can be estimated based upon the wall thickness of the casting and the temperature of the metal.

- If some of the molten metal cools too quickly, the part may exhibit shrinkage, cracks, or incomplete sections.

Removal

- After the predetermined solidification time has passed, the sand mold can simply be broken, and the casting removed.

- This step called shakeout. It is typically performed by a vibrating machine that shakes the sand and casting out of the flask.

- Once removed, the casting will likely have some sand and oxide layers adhered to the surface.

- Shot blasting is sometimes used to remove any remaining sand.

Trimming

- During cooling, the material from the channels in the mold solidifies attached to the part.

- This excess material must be trimmed from the casting either manually via cutting or sawing, or using a trimming press.

- A larger casting will require a longer trimming time.

- The scrap material that results from this trimming is either discarded or reused in the sand casting process.

Sources: