Aluminium extrusion work instructions

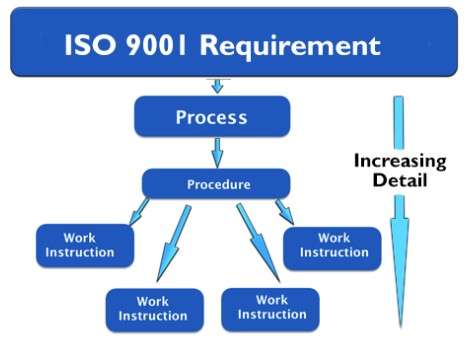

An important part of the ISO quality management system 9001, are Work Instructions. Learn about the importance of work instructions in the aluminium extrusion industry and how they contribute to ISO quality management standards (Figure 1).

Work instruction

Typical aluminum profile factories with one to two to three extrusion presses are relatively small companies.. Such companies often have difficulty quantifying, the content and format of these same work instructions.

Usually a work instruction is a special guide or step-by-step instruction on how to, how to perform a particular production task, a procedure and / or part of a general organizational or production procedure.

The degree of complexity of the products and technological processes of a particular enterprise depends on, where and how much detailed work instructions should be applied. These instructions are needed in addition to complex process procedures., as the ISO standard calls them 9001. These manufacturing processes often take the form of process instructions..

Why are work instructions needed?

are the so-called “work instructions” (Work Instructions)

- as aids for training new employees, as well as workers, who are transferred from other parts of the enterprise;

- clear instructions on the necessary equipment and tools, who are transferred from other parts of the enterprise;

- reduction in the likelihood of errors and inconsistencies, who are transferred from other parts of the enterprise;

- regulation of types of work or production tasks, for example, Maintenance, which must be carried out periodically;

- which must be carried out periodically;

- ensure that, so that all technological and operational instructions are clear and precise, and complemented each other.

Work Instruction Forms

There should not be too many work instructions. They must be really necessary for work.. Very often, in addition to work instructions, they use

- technological maps,

- process flowcharts,

- photos,

- product examples,

- customer specifications.

For work, calibration and maintenance of measuring and production equipment and tools are always available

- standard operating instructions.

Therefore, in this case, there is usually no need to develop separate work instructions.. Too voluminous instructions make sense to break into several “digestible” parts. Anyway, all these “documents” must be registered and entered into the quality system documentation system.

Not part of the technological instructions

On the other hand, a simple excerpt from a large technological instruction cannot work instructions, for example, its section or subsection.

Technological instructions, usually, write engineering workers for the same engineering workers. For a work instruction, these sections or subsections of the process instruction must be reworked as follows, that they be stated in a clear and simple language and, very desirable, with “pictures”.

Quality system element

For, so that work instructions can be part of a quality management system, including ISO 9001, they need a certain standardized format, links to more general technological processes (technological instructions). Technological instructions, in turn, must refer to and rely on relevant work instructions, as well as standards, internal technical documents, customer specifications, drawings and the like.

Work Instructions Aluminium Extrusion Plant

- Heating dies and other extrusion tools

- Editing profiles by stretching

- Cutting profiles to lengths

- Loading profiles into an aging furnace

- Procedure for testing new dies

- Die correction methods

- Dies Maintenance

- Die Etching

- Die nitriding

- Batch melting and processing of aluminum melt

- Calculation of the charge for the melting furnace

- Extrusion ingots casting

- Homogenization of extrusion ingots

- Surface pretreatment of profiles for powder coating.

- Powder coating aluminium profiles

- Rules for hanging profiles for anodizing

- Running the anodic oxidation line

- Preparation and adjustment of working solutions

- Control of the appearance of finished aluminum profiles

Source: