Extrusion of aluminium

Learn the ins and outs of extrusion aluminium. Discover how this process allows for large deformations while minimizing cracking risk.

Metals extrusion

Extrudable metals

Extrusion of metals is the process, in which a billet, usually round, is pressed by a stem at high pressure through a tool of the desired shape, the die, to one or more lengths (Figure 1). The process is used mainly for the production of bar, wire, tubes, and profiles in

- aluminum alloys and

- copper alloys.

Figure 1 – The principle of extrusion [2]

Сompressive stress state

During extrusion, a compressive stress state is developed throughout the billet (Figure 1). It enables large deformations to be achieved with a low risk of cracking.

The ratio of the billet cross-sectional area to that of the extruded section is known as the extrusion ratio. It usually falls in the range 10 to 100 and more in special cases.

This requires:

- the material’s being extruded to have a low flow stress

- a high specific press pressure of up to 1000 N/mm2.

Extrusion is therefore normally carried out at a high temperature:

- aluminum alloys usually in the range 420 to 525 ºC

Two main types of extrusion

Figure 2 illustrates the two most important types of extrusion [2]:

- (a) direct

- (b) indirect.

Figure 2 – Variation of friction components and longitudinal speed components

Figure 2 – Variation of friction components and longitudinal speed components

of metal flow in the reduction zone across the billet cross section in

the case of (a) direct, and (b) indirect extrusion processes.

(VD, VC, and VR are speed of die, container, and ram, respectively) [2]

Direct extrusion (forward extrusion)

- A stem, with a dummy block in front, pushes the billet in a stationary container through a tool of the desired shape, the die.

- Relative movement takes place between the billet and the container (Figure 3a).

Indirect extrusion (backward extrusion):

- The die is located in front of a hollow stem and pushed against the billet by the forward movement of the container closed at the back.

- There is no relative movement between the billet and the container (Figure 3b).

- There is no relative displacement between the billet and the container. As a result, there is no frictional slress at the billet/container interface.

- Therefore, the extrusion load and the temperature generated by deformation and friction are reduced [5].

Figure 3 – Typical load versus ram displacement curves

Figure 3 – Typical load versus ram displacement curves

for aluminium extrusion processes [5].

(a) Load versus ram displacement curves

for direct (forward) (1) and indirect (backward) (2) extrusion.

(b) Division of the work of deformation.

A, work of upsetting billet;

B, work needed to initiate deformation;

C, work of deformation;

D, work needed to overcome friction and shearing in direct extrusion

Direct extrusion versus indirect extrusion

The indirect method affords the following advantages:

- Longer initial billets

- Higher extrusion speed for many materials

- Thinner butt ends

- More uniform structure over the extruded length

- Thinner sections

- Closer tolerances over the entire length of the product

- More uniform container and billet temperatures during extrusion

- Longer service life of the container and liner

But, there are some important disadvantages of indirect presses:

- Machining of billet skin is required to prevent surface imperfections.

- Size of extrusion is limited with the bore of hollow stem.

- Die handling is difficult.

- The difficulties in ram construction.

- The extruded product must travel the length of the stem before it is possible to quench. Therefore, it is not possible to do press quenching.

Because of these limiting factors indirect extrusion has not found the same extensive application as the direct process.

Extrudability of aluminium alloys

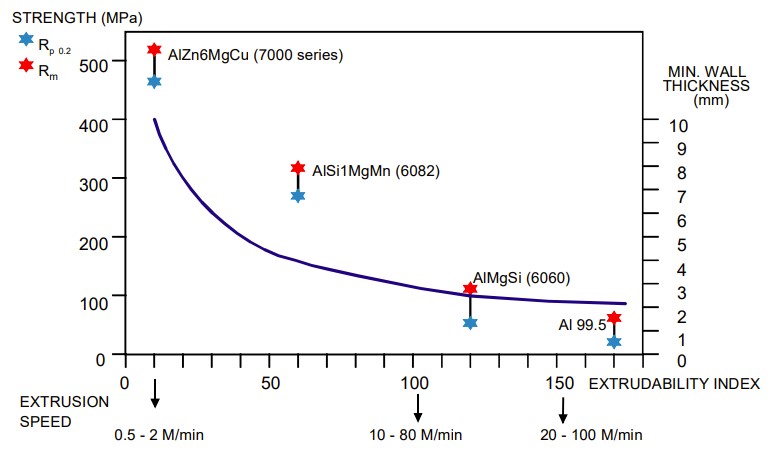

Extrudability, which can be measured by the maximum extrusion speed, is one of the most significant factors influencing cost and efficiency of the extrusion process (Figure 8). Temperature and speed parameters, together with the state of stress in the deformation zone, mainly in the die region, play a significant role in improving extrudability of a given alloy.

Easy to extrude – Soft alloys:

- Al

- AlMn

- AlMg1

- AlMgSi0.5, and

- AlMgSi0,8

Moderately difficult to extrude – Medium-strength alloys:

- AlMg2-3

- AlMgSi1

- AlZnMg1

Difficult to extrude – Hard alloys

- AlCuMg

- AlCuMgPb

- AlZnMgCu

- AlMg > 3%Mg

Figure 4 – Extrudability of various aluminium alloys: soft, medium-strength and hard [4]

Figure 4 – Extrudability of various aluminium alloys: soft, medium-strength and hard [4]

Flow stress of aluminium alloys

Figure 11 shows the range of exit speeds encountered in the extrusion of various aluminum alloys.

- The extrusion rate depends greatly on the flow stress of the alloy under the process conditions

- Exit speeds are relatively high for soft (6063 and 3003 alloys), but are quite low for hard alloys such as 7075 and 2024 [5].

Figure 5 – Extrusion rate versus flow stress for various aluminum alloys [5]

Figure 5 – Extrusion rate versus flow stress for various aluminum alloys [5]

Force and pressure capacities of extrusion presses

Presses for hot extrusion are usually rated in terms of force capacity, that is, the total force the press is capable of exerting upon the billet. However, press operation depends on the actual unit pressure exerted on the metal. For a press with a given force capacity, higher unit pressures can be obtained if the billet container is smaller in diameter. As the container increases in diameter, the unit pressure capability decreases, with a resultant decrease in extrusion capability [5].

The typical unit pressure, or the specific pressure, is listed in the table of Figure 12 for different press capacities and container sizes. The unit or specific pressure of the press has to be greater than the required pressure for a particular extrusion under certain conditions. The required pressure for extrusion could vary with the alloy and its condition, the extrusion ratio, length and billet temperature, extrusion speed, and circumscribed circle diameter [2].

- The typical maximum unit pressure that is used on most extrusion presses is about 1035 MPa.

- This pressure is near the upper limit of the mechanical strengths of most tool steels used for extrusion [5].

Figure 6 – Force and pressure capacity of typical aluminium extrusion presses.

Figure 6 – Force and pressure capacity of typical aluminium extrusion presses.

(The fragment of the table of the source [2])

Sources: