An aluminium extrusion container

Learn about the major components of aluminium extrusion container and its importance in achieving accurate alignment.

Aluminium extrusion press

The major components

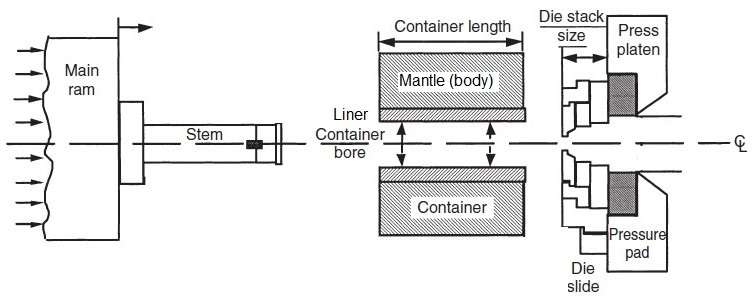

The major components of conventional aluminium extrusion presses are shown in Fig. 1. The most important extrusion toolings are the three components [1]:

- Extrusion container with liner

- Stem with dummy block

- Die slide with die stack

The role of the tooling in the extrusion process is seemly simple [2]:

- A hot billet is inserted into one end of the liner and pushed out the other end.

- This is done repeatedly and as quickly as possible.

- Extrusions should be made rapidly, one after another, without interruption or delay.

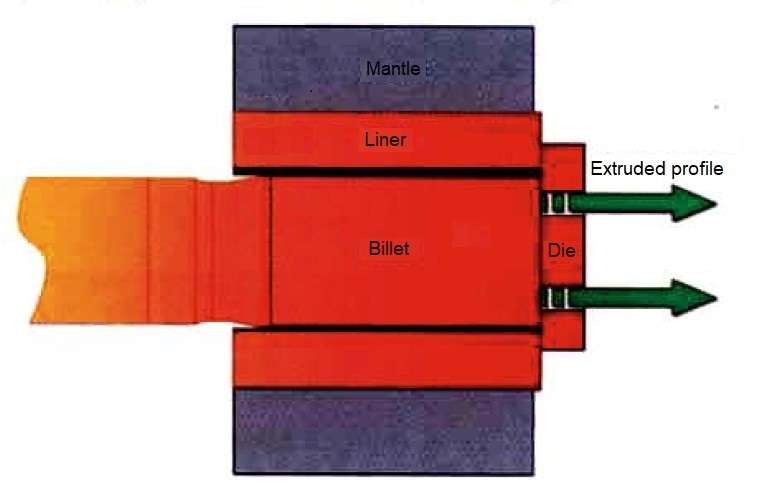

Fig. 1 – The major components of a conventional (direct) aluminium extrusion press [1]

Fig. 1 – The major components of a conventional (direct) aluminium extrusion press [1]

Mechanical alignment of extrusion press

The press should have accurate and adjustable alignment:

- the stem, container, and die should lie on the same centerline as shown in Fig. 1.

Aluminium extrusion container

The heavest tool

Among extrusion tools, the aluminium extrusion container is the heaviest and the most expensive. Usually, containers represent about 80% of the total mass of the tooling. For example, an 8-inch container weighs about 4 tons while the total weight of the stem, dummy block, die set, and bolster is under a ton [2].

Container mantle

The container mantle has the function of supporting the liner in order to prevent a breakage of the liner under high extrusion pressures. The pressure needs to be distributed homogenously from the liner to the container. This provide a proper shrink fitting process. This external pressure on the liner balances the generated pressure during the extrusion [3].

Container liner

The liner is under severe wear due to contact with the billet surface and the dummy block. Therefore, the liner must have high hardness and wear resistance at elevated temperatures,

Good container liner can withstand 30,000 to 40,000 cycles of aluminium extrusion [1]. After the end of its service life, the container is replaced with a new one.

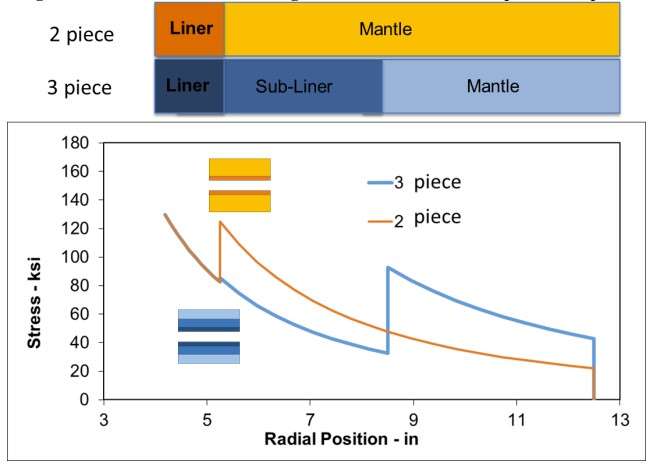

Two- or three piece container design

The container is designed to withstand high stresses at elevated temperatures. However, the container is more highly stressed at the die end where the pressure and temperature are higher and applied over longer times because the billet length decreases as extrusion proceeds. The container can be of a 2-piece or 3-piece design.

In a 2-piece container, the body’s ID is under more stress than that of a 3-piece container as it is further away from the pressurized liner (Figure 2). In a 3-piece container, the sub-liner is supported through the shrink fit with the body, which neutralizes a portion of the stress during the process and decreases the stress on the subliner.

Figure 2 – Stress distribution in a 2-piece and a 3-piece container with 620 MPa face pressure [2]

Figure 2 – Stress distribution in a 2-piece and a 3-piece container with 620 MPa face pressure [2]

The criteria for the two- or three part design of container are [1]:

- Inner pressure in the container liner

- The maximum outside container diameter

Container mounting

The container is mounted in special way [1]:

- When it is subjected to heat, it expands freely on all sides while retaining its position relative to the press centerline.

- The container can be turned axially to ensure even wear of the liner.

- The container is locked into the container holder, which can move by hydraulic means along the longitudinal axis of the press.

Container heating

The container is heated to a temperature of about 430 °C by a resistance heating unit installed in the container itself or in its holder. Due to the mass and length of the huge container of large capacity presses, the inside temperature of the liner is difficult to maintain with conventional wraparound container heating elements [2].

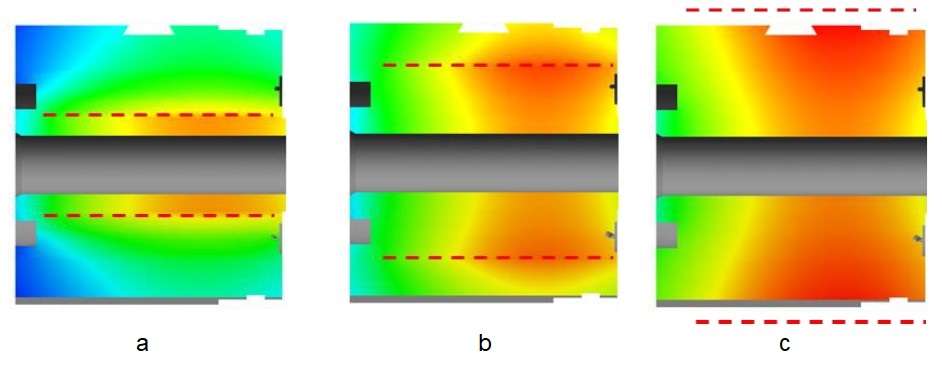

Fig. 3 – The effect of heating element location on temperature distribution in the container [2]:

Fig. 3 – The effect of heating element location on temperature distribution in the container [2]:

a – elements on the liner;

b – elements at centre of mantle;

c – externally heated container

Container temperature

Container heat generation

During extrusion, there is an enormous amount of heat generated within the container depending on:

- the billet length

- billet temperature

- alloy types

- extrusion speed and

- extrusion ratio.

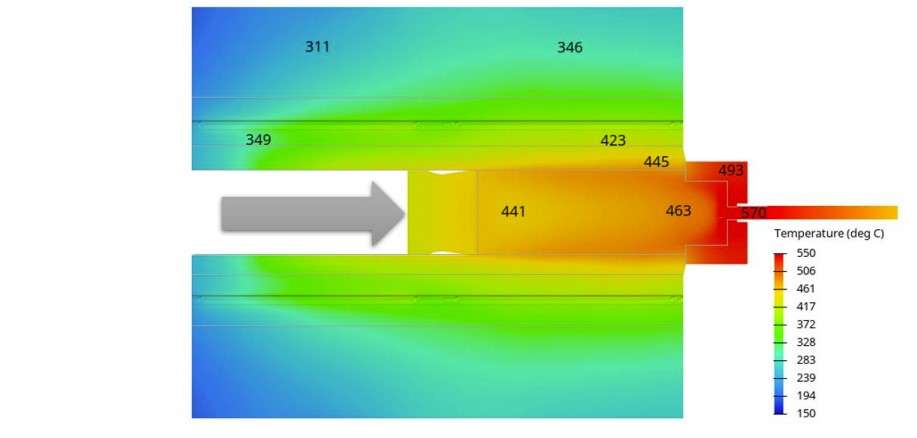

The temperature increase can be as much as 150°C near the die region (Fig. 4).

Figure 4 – Temperature distribution during the extrusion of 6063 aluminum alloy [2].

Figure 4 – Temperature distribution during the extrusion of 6063 aluminum alloy [2].

Container thermal alignment

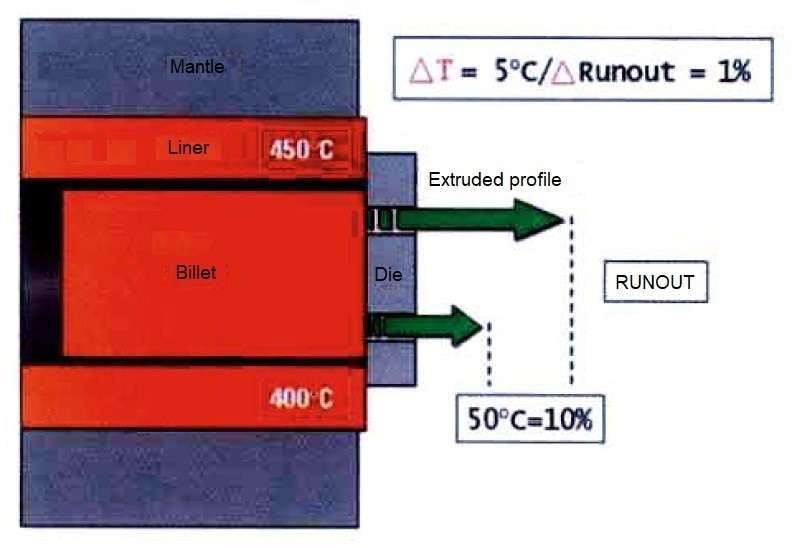

The press extrusion tools must be aligned not only mechanically, but also thermally (Fig. 5) [4]:

- The die must be always mounted exactly in the center of the container.

- The temperature of the container liner should remain uniform, bottom to top, to preserve the uniformity of the temperature of billet. The temperature non-uniformity interfere the consistency of metal flow from container into the die (Fig. 6).

Figure 5 – The ideal thermal alignement of mantle and liner [4]

Figure 5 – The ideal thermal alignement of mantle and liner [4]

Figure 6 – The results of of non-uniform liner temperature [4]

Figure 6 – The results of of non-uniform liner temperature [4]

Extrusion Container Maintenance

Container-liner assembly is considered expendable tooling and are therefore expected to have a finite service life. They are one of the most abused parts of an extrusion press. Excluding the dies they are the only part of the press that has to do its work at a constantly elevated temperature [5].

Following are the most common causes of premature container or liner damage and failure:

- Improper pre-heating

- Over-heating

- Fatigue cracks

- Misalignment between the stem and the container

- Misalignment of the press frame (tie rods)

- Insufficient bearing area between the die and the liner face

- Aluminum buildup on the face of the die

- Caved platen pressure ring or caved platen

Sources:

- Aluminum Extrusion Technology / P.K. Saha – ASM Internatonal – 2000

- Material Selection for Extrusion Containers – Ya. Mahmoodkhani and P. Robbins – Castool – 2022

- Extrusion Press Container – Damatool – 2023

- Extrusion – A major change in focus / P. Robbins, Castool – 2005

- Extrusion Container Care and Maintenance /James M. Pope // Tooling – Extrusion Press Maintenance Manual – 2022