Aircraft Fastening: Which is Better?

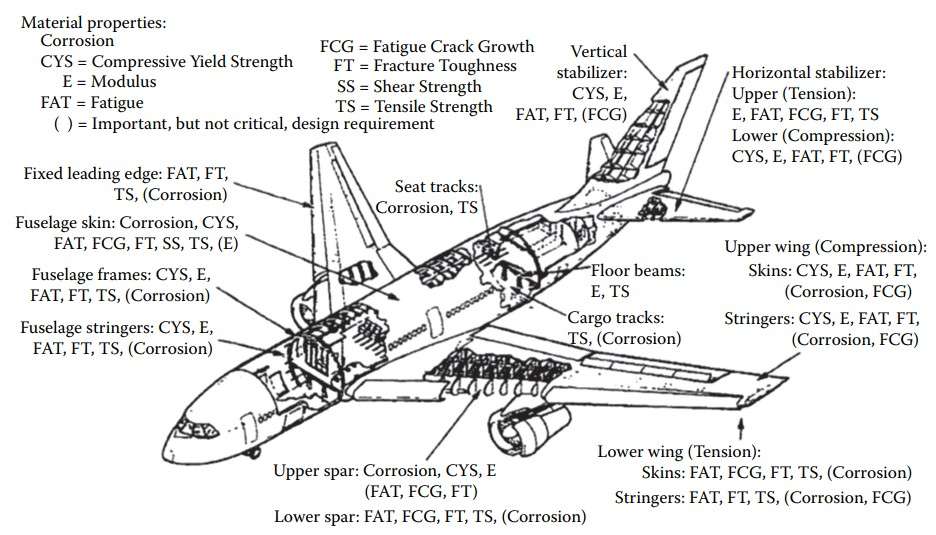

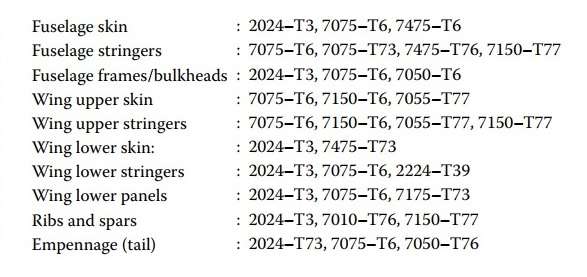

Aircraft structural materials used in major components such as the fuselage, wings, landing gear, and empennage are subject to a range of loading. For example, an aircraft fuselage is subjected to various forces including compression, tension, bending torsion and pressurization as it is carrying the entire payload. As another example, the upper surface of an aircraft wing is subjected to compression and the lower surface to tension during flight. The most commonly used aircraft structural materials are high-strength aluminum alloys, titanium alloys, and carbon fiber-reinforced polymer composites.

Aircraft components need to be selected and manufactured to adequately combat the environment, temperature, loading, compatibility, and so on. The 2024 and 7075 aluminum alloys are used in the upper wing skins and stringers as they have a good combination of the following properties: compressive yield strength, modulus, fatigue, fracture toughness, fatigue crack growth, and corrosion.

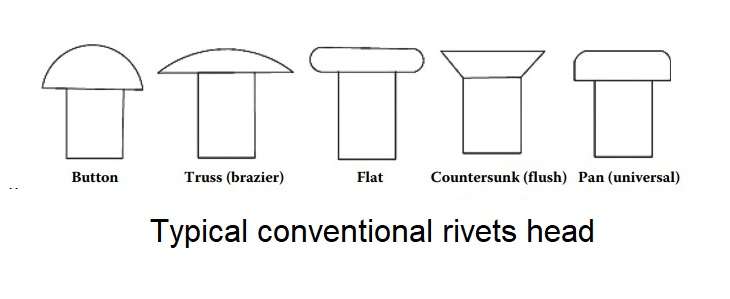

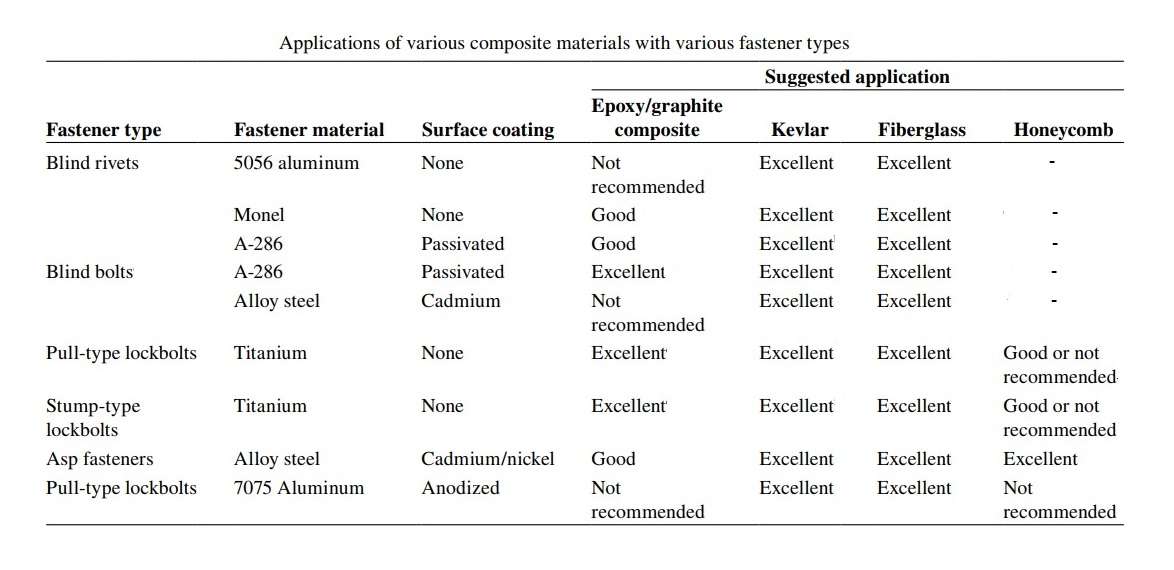

Structural materials such as aluminum alloys or fiber-reinforced polymer composites need to be joined in aircraft. The selection of fasteners, bolts, rivets, adhesives, and other methods need to be quantitatively assessed in order that the correct design for the component and joining method is identified. There is a variety of fasteners, bolts, and rivets, made using a variety of materials. Aluminum rivets are often used to join aluminum components in an aircraft. Rivets do not perform well under tension loading, but perform better in shear, thus limiting the application specifically for these purposes.

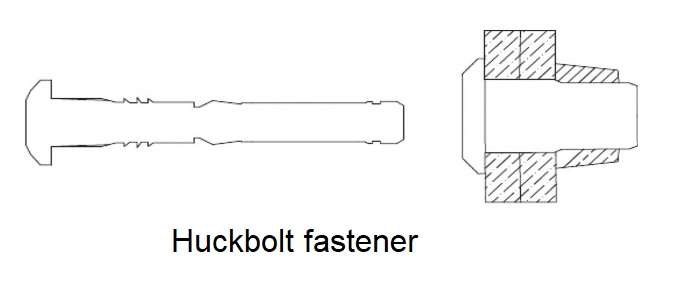

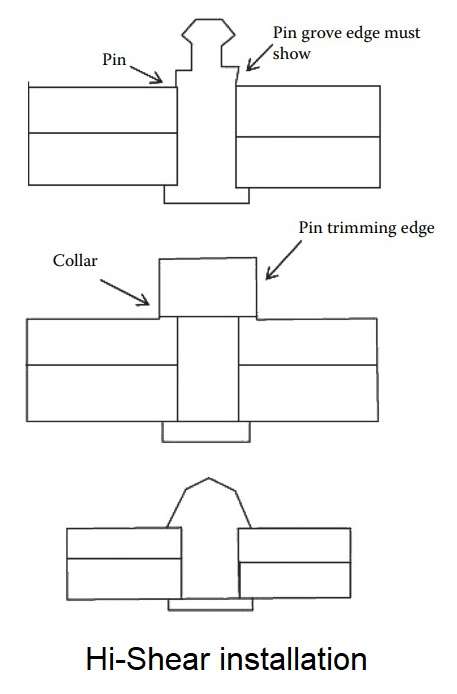

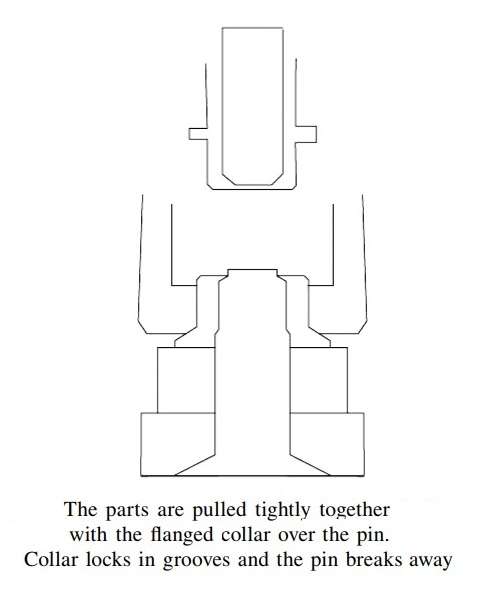

Huckbolts as shown in the figure have their stem broken in the position of the notch. These bolts are available in aluminum, stainless steel, and carbon steel. Generally, aircraft rivets are of aluminum alloy grade such as 5056, 2117, 2017, 2024, and 1100.

High-shear pin rivets are made from aluminum, stainless steel, titanium, or carbon steels. However, this type of rivet is only used for shear-loading purposes.

Lightweight grooved proportioned lockbolt is manufactured with a titanium shank which has a highshear capability and is typically used in joining composite materials The extra-large sizes made for the heads and collars have been designed intentionally in this manner in order to minimize stresses on the composite material.

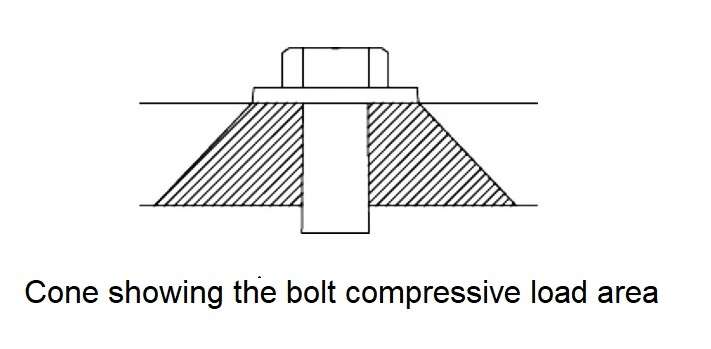

Bolts are designed to clamp material together, and even though the bolt may be adequate to support a particular structure and load requirement, consideration must also be given to the modulus of elasticity and stiffness of the components that are being clamped together. Therefore, an understanding of each of the materials being clamped or joined together is necessary. Bolts manufactured from steel, for instance, have coatings applied in order to help protect them from corrosion.

Figure 7

The use of composites translates to a reduced number of rivets and fasteners to be used. Drilling of holes into composites to insert fasteners poses many challenges because the fibers are damaged, a region of high stress concentration may be formed, and the hole is a site for the ingress of water or moisture. The insertion of aluminum fasteners or the contact of aluminum components with carbon fibers creates galvanic corrosion due to the large difference in electrical potential. Titanium alloy (Ti-6Al-4V) is a typical fastener where there is composite joining due to its better compatibility (elimination of galvanic corrosion) and increased strength properties.

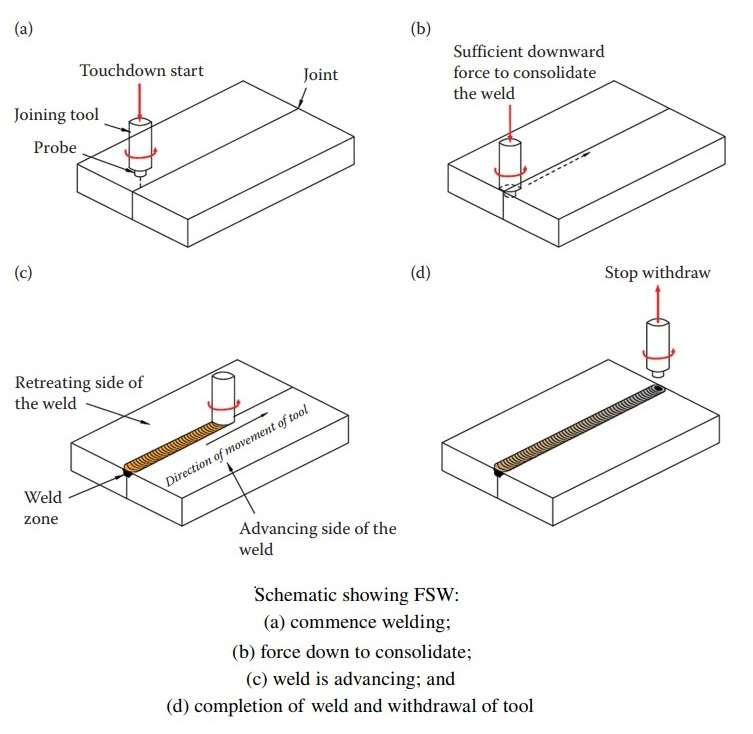

Substitution of rivets and fasteners for welding is also on the increase in aircraft because laser beam welding (LBW) and friction stir welding (FSW) both reduce cracking, porosity, and better properties achieved due to deeper penetration, and reduce the heat-affected zone which would typically be undesirable with conventional arc welding such as metal inert gas and tungsten inert gas welding.

Fasteners for aircraft structural applications are not only dependent upon their own properties but are also very much dependent upon the structures to which the fasteners are connected. All materials must be examined on a micro and a macro level, and design philosophies such as “damage-tolerance” and “fail-safe” are necessary to take into account with structures adjacent and in connection with any fasteners, bolts, or rivets. Fastener design alone is not enough, nor is it simple to design, because many factors must be taken into account to ensure longevity so that it is fit for purpose.

The source: Aerospace Fasteners: Use in Structural Applications / George Nadim Melhemt // Encyclopedia of Aluminum and Its Alloys – 2019