Adhesive bonding of aluminium

Adhesive bonding is defined as the process of joining parts using a non-metallic substance (adhesive) which undergoes a physical or chemical hardening reaction causing the parts to join together through surface adherence (adhesion) and internal strength (cohesion).

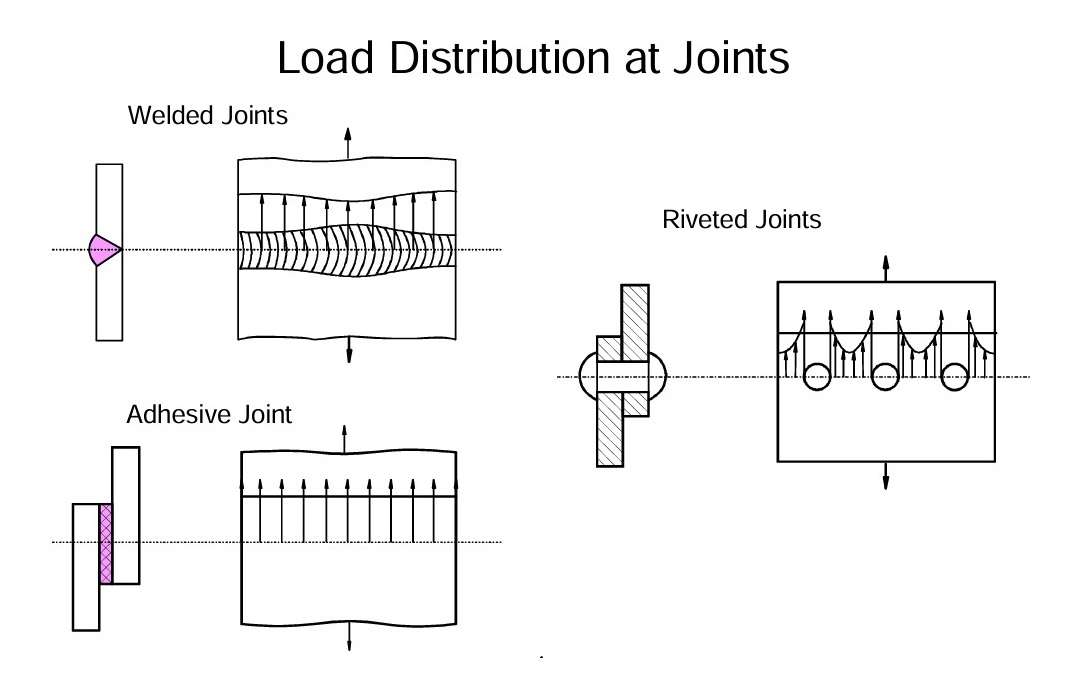

Adhesive joining is classified within the manufacturing processes in the main group joining, the group combination of substances and the subgroup adhesive joining, together with welding and brazing/soldering. The main advantage of adhesive joining over welding, riveting, brazing and screw fastening is that the load is distributed more evenly at right angles to the loading direction. In the direction of the loading itself, however, this is valid only for scarfed adhesive joints.

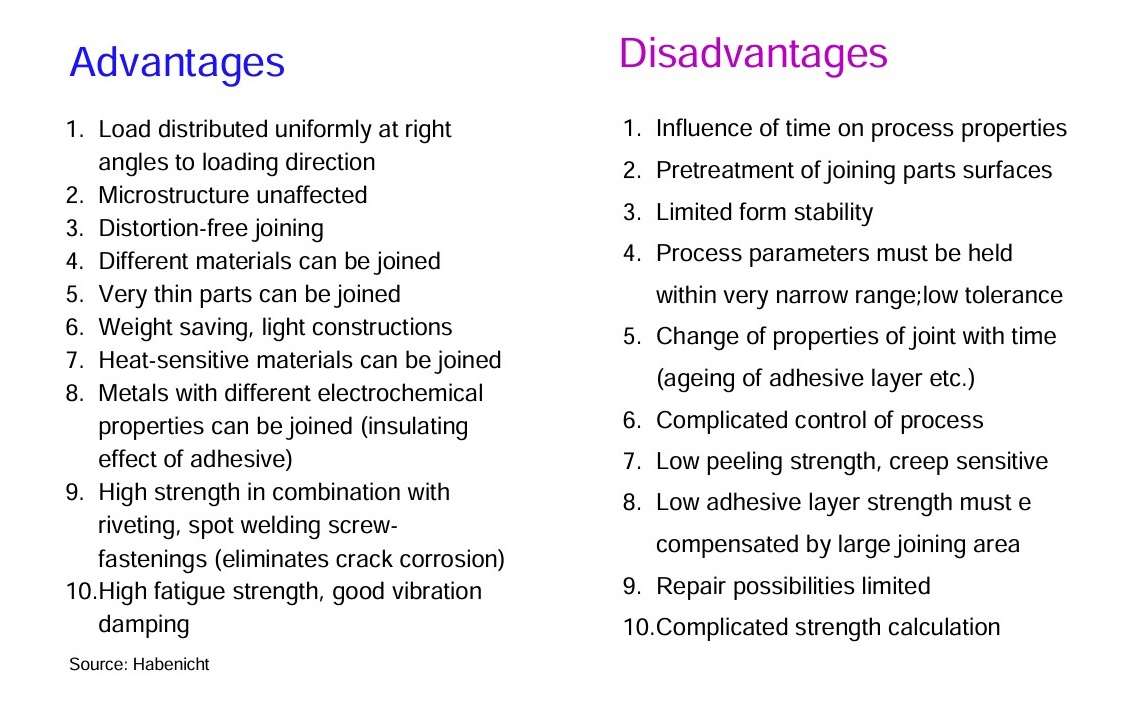

The figure shows the advantages and disadvantages of adhesive joining. It serves as a help in choosing the appropriate joining method.

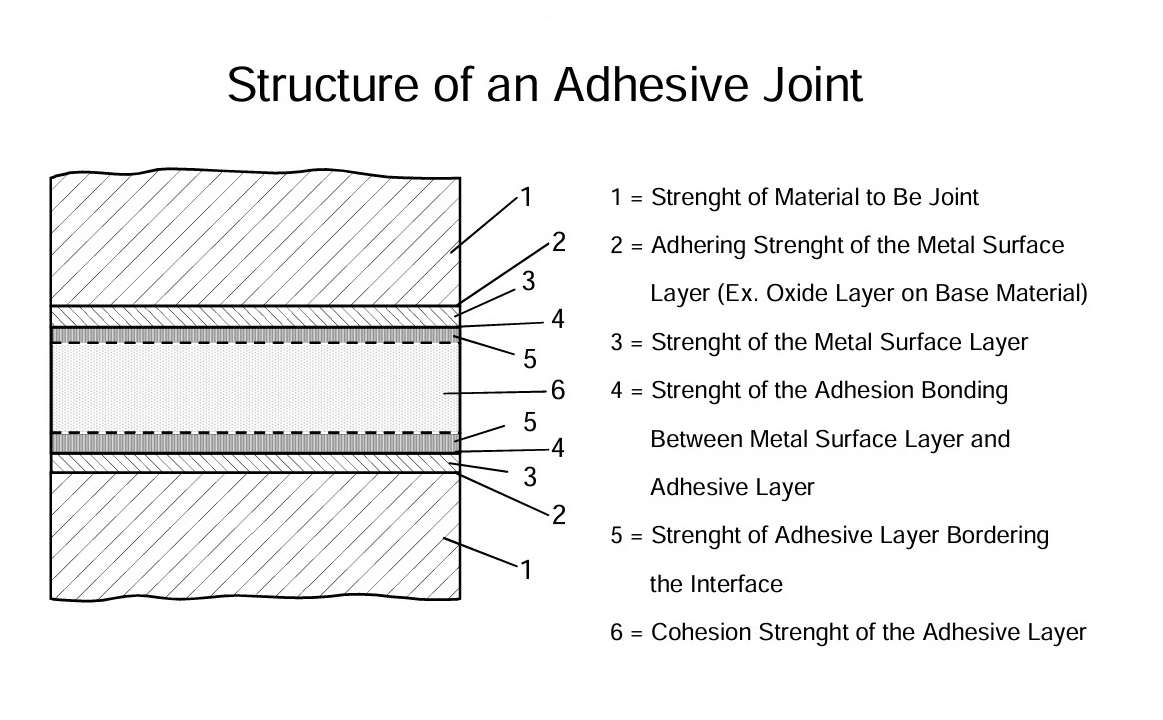

Adhesive joints are composite systems whose strength depends on both the geometrical design and loading type. As in every composite system consisting of different members, the overall strength is limited by the weakest member.

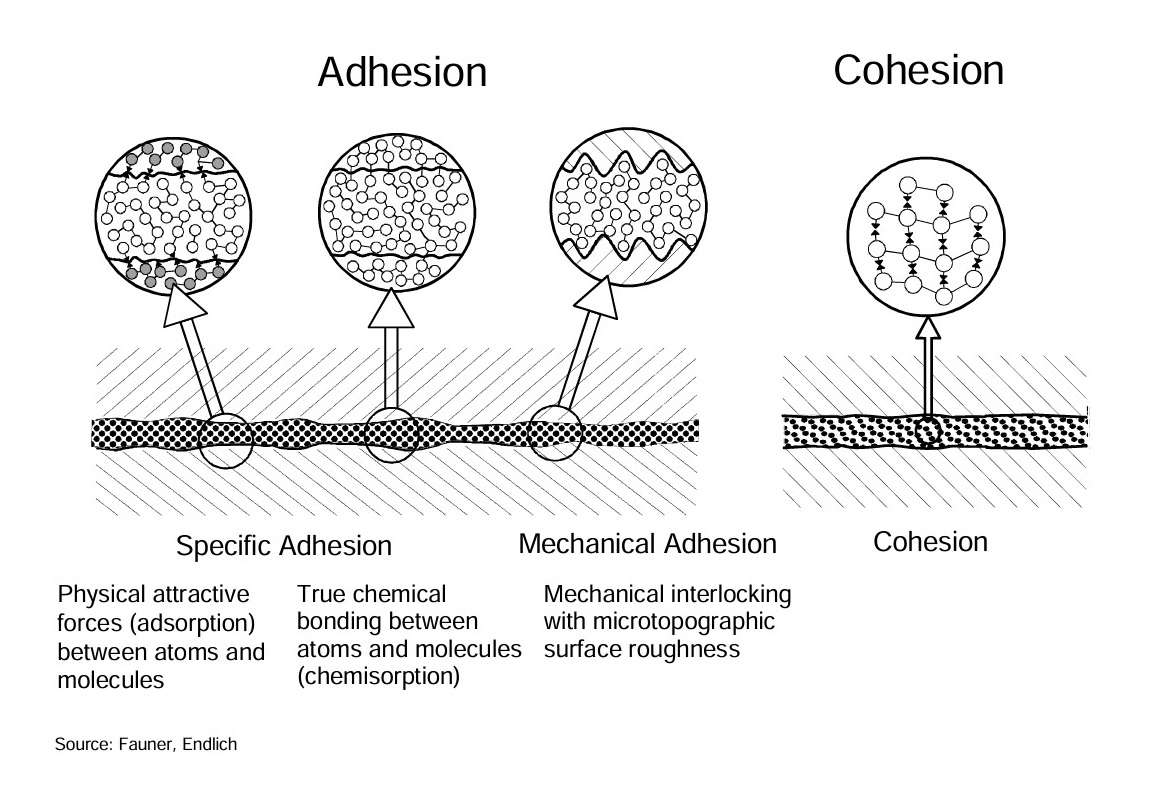

Adhesion and cohesion. Adhesion is defined as the adhesive force acting between the adhesive and the surface of the material. This force is the result of the mechanical interlocking between adhesive and the material surface roughness (mechanical adhesion) as well as the physical and chemical interaction between the adhesive and the material (specific adhesion). Cohesion is the strength of the adhesive itself. This is a result of the mechanical entangling and interlocking of the adhesive molecules and their physical and chemical affinity for each other.

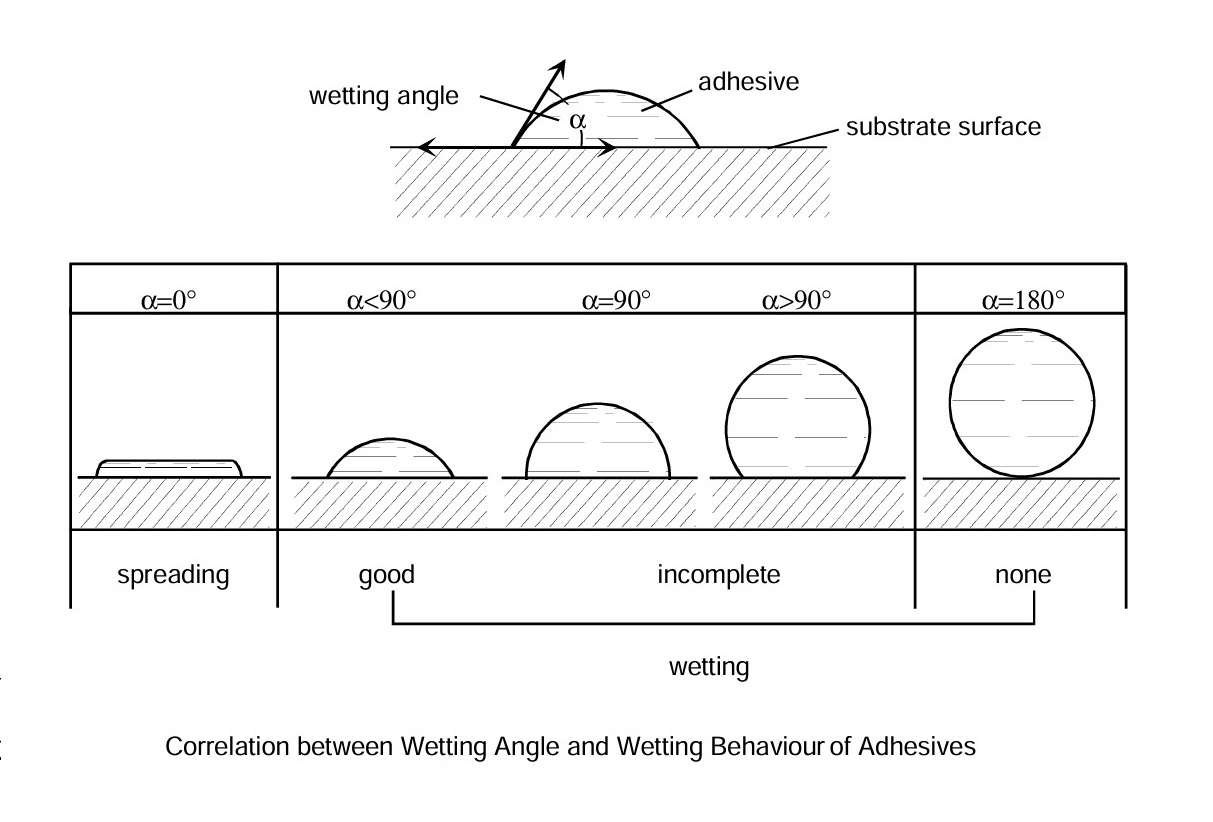

A necessary condition for attaining high adhesion forces is the ability of the adhesive to wet the surfaces of the joining parts properly. The wetting is optimal when the angle of contact α does not exceed 30°. This can be achieved, in principle, by a suitable surface treatment of the joining parts and by choosing an appropriate viscosity for the adhesive.

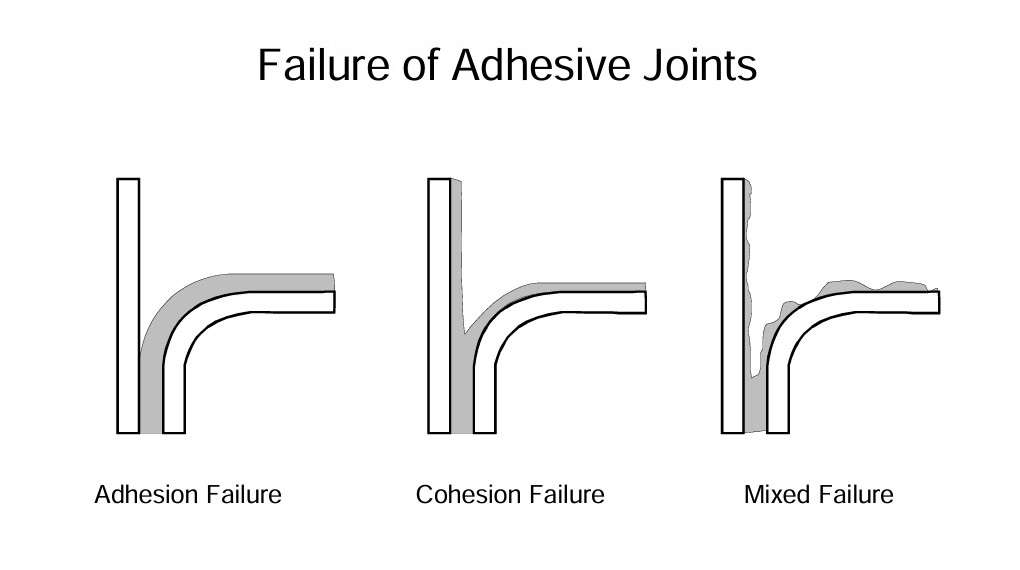

The separation of adhesive joints occurs due to the failure of adhesion or cohesion or of both (i.e., mixed adhesion and cohesion failure). A cohesion failure is to be strived at. An adhesion failure indicates that the surfaces of the parts to be joint had not been properly pretreated.

The source:

TALAT Lecture 4701 – Adhesive Bonding – Terms and Definitions / Lutz Dorn – European Aluminium Association – 1994