6060 aluminium alloy

Chemical composition

Nominal chemical composition

Al-0,5Mg-0,45Si

Chemical composition according to EN 573-3

Table 1 – The chemical composition of 6060 aluminium alloy by EN 573-3

in comparison with 6063 aluminium alloy

Metallurgical characteristics

- Wrought

- Heat hardenable

- Partial analogues: 6063 aluminium alloy.

- 6060 aluminium alloys has an excessive content of Si relative to the magnesium.

- Maximum iron content: 0,30 compared with 0,35 % in 6063 aluminium alloy.

- The place of 6060 aluminium alloy among other 6xxx series alloys see at Figure 1.

Figure 1 – AlMgSi extrusion ingot alloys used in Europe and USA [5]

Figure 1 – AlMgSi extrusion ingot alloys used in Europe and USA [5]

Designations

- EN 573-3: 2013: EN AW-6060 и EN AW-Al MgSi

- Teal Sheet – Aluminium Association: 6060

- Unified Numbering System (UNS): А96060

- ISO 209:2007: 6060

- DIN 1725-1 (canceled): AlMgSi0.5 and 3.3206

Typical applications

- Building constructions, such as windows, facade constructions, enter the store, winter gardens.

- Internal partitions.

- Heat dissipating elements of electronic devices, including, computers.

- Elements of engineering equipment.

- Interior equipment of passenger cars.

- Irrigation, heating and cooling pipes.

- Furniture and office equipment.

Mechanical properties

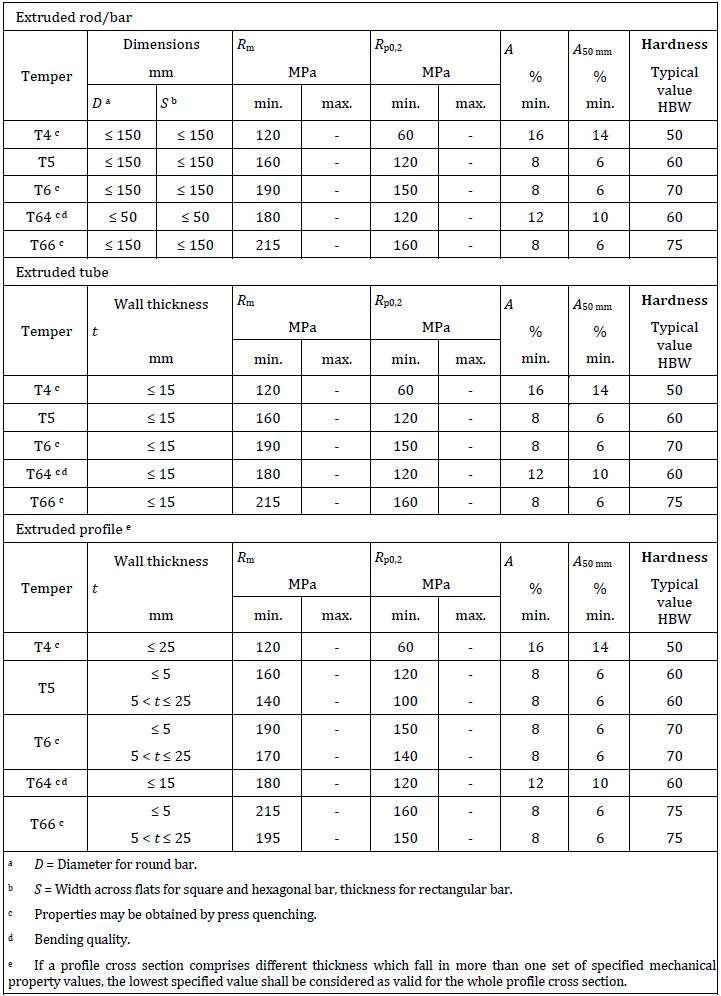

Table 2 – Requirements of EN 755-2 to mechanical properties

extruded rods, tubes and profiles of 6060 aluminium alloy

Poisson’s ratio

- 0,33

Elastic modulus (Young’s modulus)

- in tension and compression – 69000 MPa

- Shear – 26000 MPa.

Physical properties

Density

- 2,70 g / cm3 at 20 ° C

Melting interval

- From 600 to 655 ° C.

Coefficient of linear thermal expansion

- 23,5 micrometers/(m K)

- In the range from 20 to 100 ° C.

Thermal conductivity

- 200 W / (m K)

Specific heat

- 880-900 J / (kg K)

Electrical conductivity

- 52 % IACS (54 % in relation to annealed copper)

Technological properties

Extrudability

- See Figure 2

Figure 2

Weldability

- Good arc-welded under inert gas, in particular, argon arc welding, as non-consumable electrode (GTAW-TIG), and consumable electrode (GMWA-MIG).

- Conventional welding alloy – 4043.

Homogenization

- 580-585 ° C

- At least 2 hours.

Annealing

- 420 ° C.

Solution treatment

- 510 ° C.

Artificial ageing

- 185 ° C

- 5 hours.

Bending

- T4 temper.

Sources:

1. European Aluminium Association – http://www.alueurope.eu

2. EN 573-3

3. EN 755-2

4. TALAT 1302

5. Tom Hauge, Hydro Aluminium, Norway – IHAA Symposium, 25th of September 2014, New York